Computer vision cube calibration based three-dimensional measurement method

A computer vision and three-dimensional measurement technology, applied in the field of computer vision, can solve the problems of complex calibration system, inability to obtain measurement results in real time, and expensive system, and achieve the effect of expanding the calibration range, reducing economic costs, and improving calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

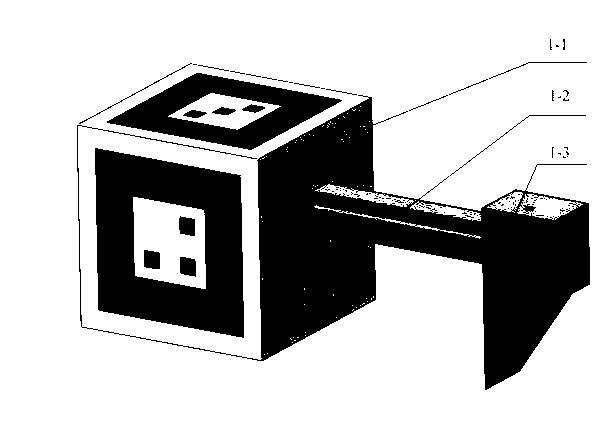

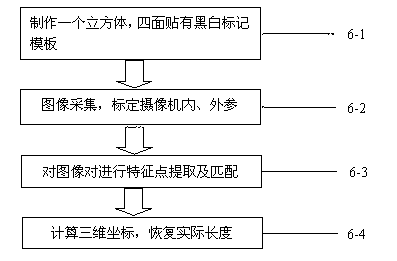

[0021] See figure 1 with image 3 , This three-dimensional measurement method based on computer vision cube calibration is characterized in that it includes the following steps:

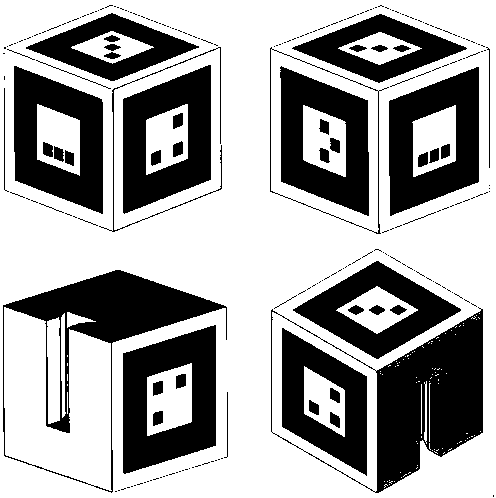

[0022] 1) Use a cube with a black and white mark on the surface—a combination pattern of a large black and white box and three small black squares with its own clamping device as a calibration object;

[0023] 2) Use the dot matrix graphic template to calibrate the camera internal parameters, and then use the calibration cube to calibrate the camera external parameters and collect image pairs;

[0024] 3) Use the SIFT method to identify and match the feature points of the acquired image pairs;

[0025] 4) Finally, the three-dimensional coordinates of the key points are calculated and the actual length is restored.

Embodiment 2

[0027] This embodiment is basically the same as the first embodiment, and the special features are:

[0028] 1) The black and white marks are a set of templates, and they are different.

[0029] 2) The cube calibration object and its own clamping device are 50*50*50mm 3 , The clamping device can be slid and fixed freely between 0 and 50mm.

[0030] 3) The camera calibration is divided into two independent parts, which internally participate in the calibration of external parameters. Extract multiple images, use the image coordinate system, the world coordinate system and the relationship between the image coordinate system to obtain the projection matrix, and perform QR decomposition of the projection matrix to obtain the internal and external parameters of the camera.

[0031] 4) The center of any black and white mark template of the calibration cube is used as the origin of the three-dimensional coordinates to obtain the transfer matrix when the camera takes pictures, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com