EU-1/Beta composite molecular sieve, and catalyst for toluene disproportionation and transalkylation and application of catalyst

A composite molecular sieve, EU-1 technology, applied in the field of EU-1/Beta composite molecular sieve, can solve the problems of increasing catalyst preparation steps, increasing catalyst cost, etc., achieving the effects of low catalyst cost, reducing secondary reactions and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A kind of preparation method of EU-1 / Beta composite molecular sieve of the present invention comprises the steps:

[0017] (1) Mix EU-1 molecular sieve, silicon source, aluminum source, alkali, water and templating agent uniformly according to the ratio to obtain a gel. The ratio of each component in the gel is calculated as follows (in the distribution ratio of each component SiO 2 and Al 2 o 3 SiO as oxide in silicon source and aluminum source 2 and Al 2 o 3 content, excluding SiO in terms of oxides in EU-1 molecular sieves 2 and Al 2 o 3 ):

[0018] EU-1 / SiO2 2 (gram / gram)=0.17~0.40;

[0019] R / SiO 2 (mol / mol)=0.36~0.54;

[0020] SiO 2 / Al 2 o 3 (mol / mol)=38~148;

[0021] Na 2 O / SiO 2 (mol / mol)=0.45~0.54;

[0022] h 2 O / SiO 2 (mol / mol)=20~33;

[0023] Preferably:

[0024] EU-1 / SiO2 2 (gram / gram)=0.17~0.40;

[0025] R / SiO 2 (mol / mol)=0.45~0.54;

[0026] SiO 2 / Al 2 o 3 (mol / mol)=63~125;

[0027] Na 2 O / SiO 2 (mol / mol)=0.45~0.54;

...

Embodiment 1

[0043] (1) Synthesis of EU-1 / Beta Composite Molecular Sieve

[0044] Add sodium aluminate, distilled water, and tetraethylammonium hydroxide successively into the beaker, stir evenly, then add EU-1 molecular sieve, stir for 10 minutes, finally add white carbon black, stir for 30 minutes, and then put it into the synthesis kettle.

[0045] The ratio of materials in synthetic materials is:

[0046] EU-1 / SiO2 2 (g / g) = 0.35;

[0047] R / SiO 2 (mol / mol) = 0.50;

[0048] SiO 2 / Al 2 o 3 (mol / mol)=112;

[0049] Na 2 O / SiO 2 (mol / mol) = 0.52;

[0050] h 2 O / SiO 2 (mol / mol)=32.

[0051] The synthetic material was heated in an oven at 140°C for 4 days, the obtained product was filtered, washed with distilled water until neutral, dried, and calcined at 550°C for 5 hours to obtain EU-1 / Beta composite molecular sieve.

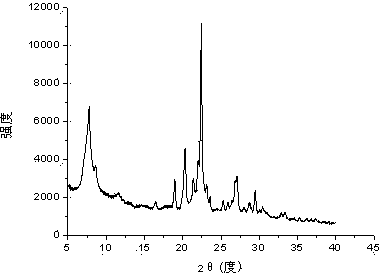

[0052] The XRD spectrum of this EU-1 / Beta composite molecular sieve is as figure 1 shown. It can be seen that the characteristic peaks of EU-1 molecular sie...

Embodiment 2

[0060] Take 75 grams of hydrogen-type EU-1 / Beta composite molecular sieve A prepared in Example 1, 104.2 grams of SB powder, and 3.75 grams of scallop powder, mix well, then add 85ml of deionized water and 3.75ml of concentrated nitric acid (66.5w%) in the mill Fully knead on the press to make it into a paste-like plastic, extrude a cylindrical rod with a diameter of 1.5mm on the extruder, dry at 110°C for 8 hours, and then bake at 550°C for 4 hours in an air atmosphere to obtain catalyst C2. The catalyst composition and evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com