Axial flow type oil smoke ventilator

A range hood, axial flow technology, applied in the field of range hood, can solve the problems of difficult installation, reduction of effective use area, increase of construction cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

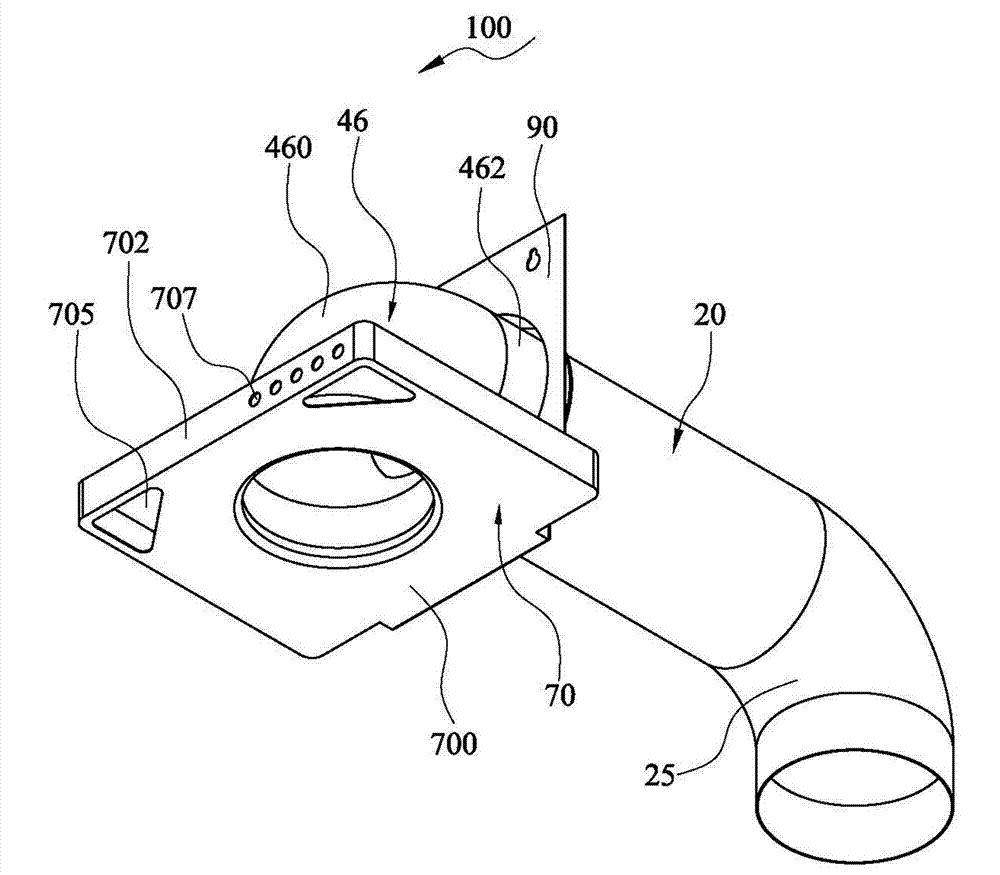

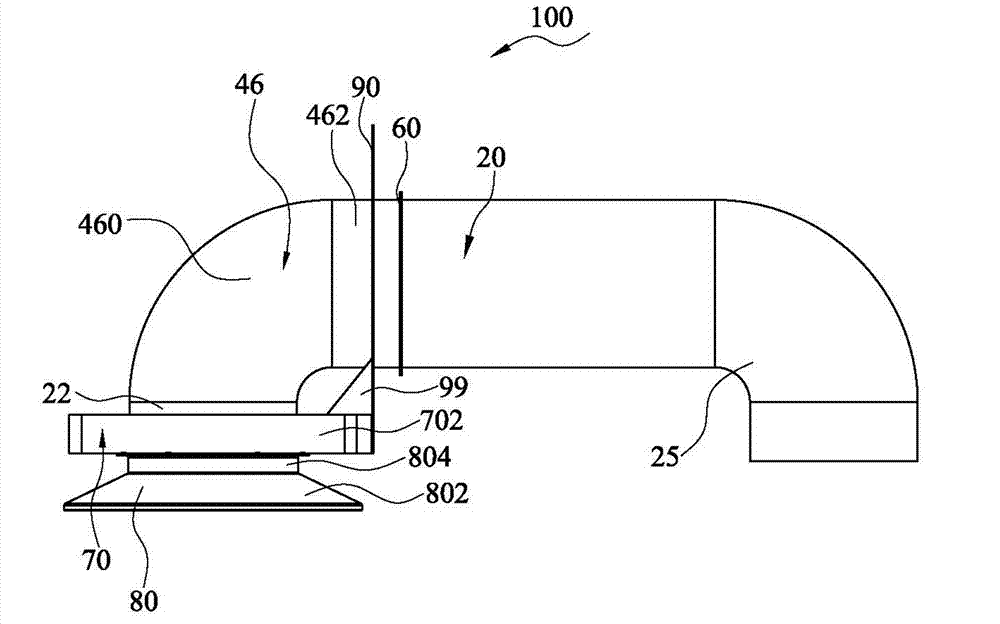

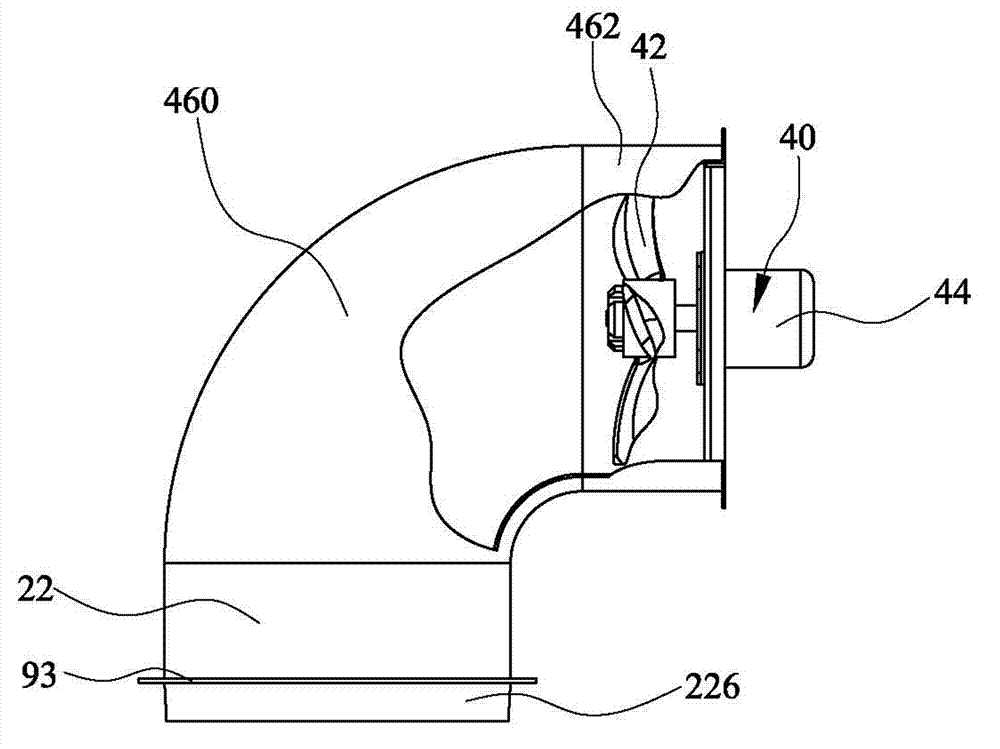

[0031] like Figure 1 to Figure 3 As shown, the axial flow range hood 100 of an embodiment of the present invention includes: a curved tube axial flow range hood fan 40 .

[0032] The curved tube axial flow oil fume fan 40 includes: a curved duct 46 , a fan body 42 disposed in the curved duct 46 , and a fan motor 44 connected to the fan body 42 . The fan motor 44 is fixed in the curved duct 46 through a motor bracket 50 .

[0033] Further, the curved duct 46 of this embodiment includes: a curved section 460 and an exhaust section 462 connected to one end of the curved section 460 . The air inlet of the curved duct 46 is oppositely disposed at the other end of the curved section 460 . The air outlet of the curved duct 46 is opposite to the other end of the air exhaust section 462 . In this embodiment, the fan body 44 is disposed in the exhaust section 462 .

[0034] The fan body 42 is installed on the windward side. According to the different rotation directions of the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com