Processing method for medical catheter with built-in steel wire

The technology of a medical catheter and a processing method, which is applied in the field of processing medical equipment, can solve the problems of inability to form large-scale production, and achieve the effects of high consistency of product quality and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

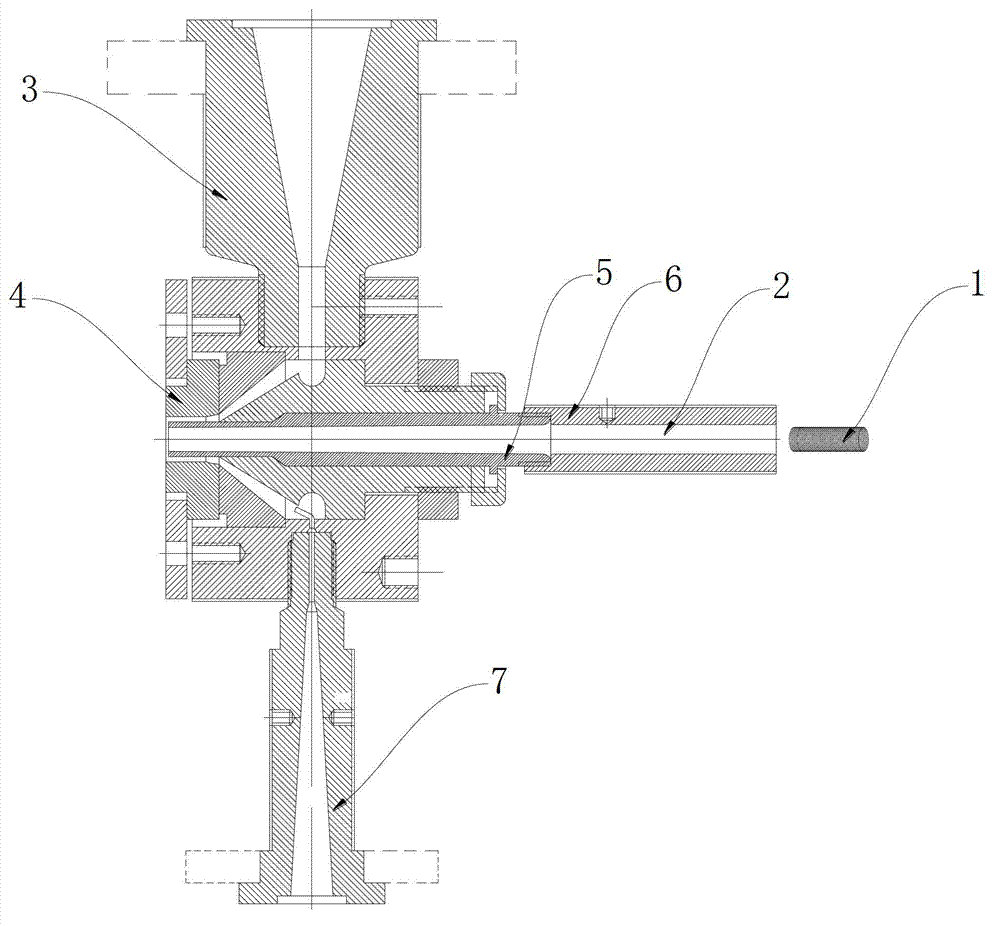

[0012] The present invention will be further described below in conjunction with accompanying drawing. The first step is to prepare the polymer material and the steel wire 1 set in the medical catheter; the second step is to extrude the prepared steel wire 1 into the steel wire guide groove 2 of the extruder, and the extruder Including die head device, described die head device comprises main material guide post 3, described guide post is provided with tapered guide cavity, core 5, mouth plate 4, described core 5 and mouth The templates 4 are provided with annular intervals with uniform thickness, and the annular intervals are connected to the diversion cavity through the diversion channel, and the diversion channel is formed from the diversion cavity to the annular interval. It is tapered and makes the wall thickness of the formed conduit gradually decrease. The core 5 is connected with a steel wire guide tube 6 in the opposite direction of the discharge, and the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com