Annular vortex coupler

A ring-shaped eddy current coupler technology, applied in the field of mechanical transmission, can solve the problems of large radial size of disc-shaped eddy current coupler, increased construction period and difficulty of work, low stability, etc., achieves small wind resistance, reduces engineering expenses, increases Effects on Reliability and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

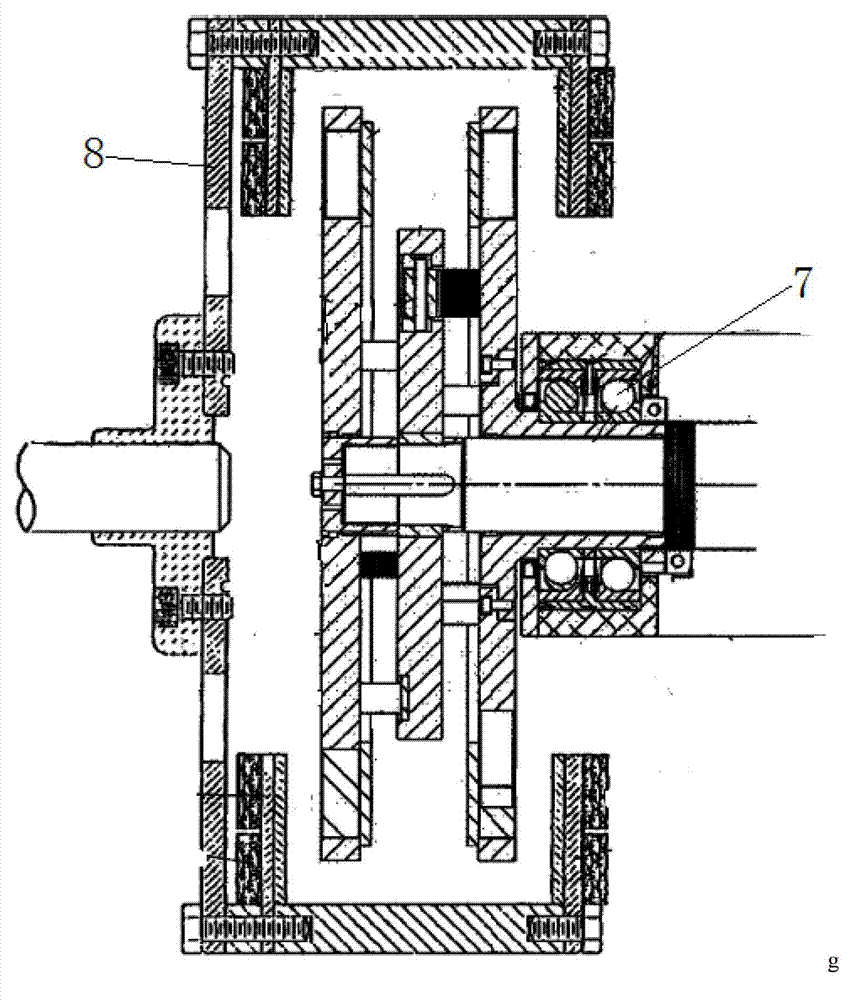

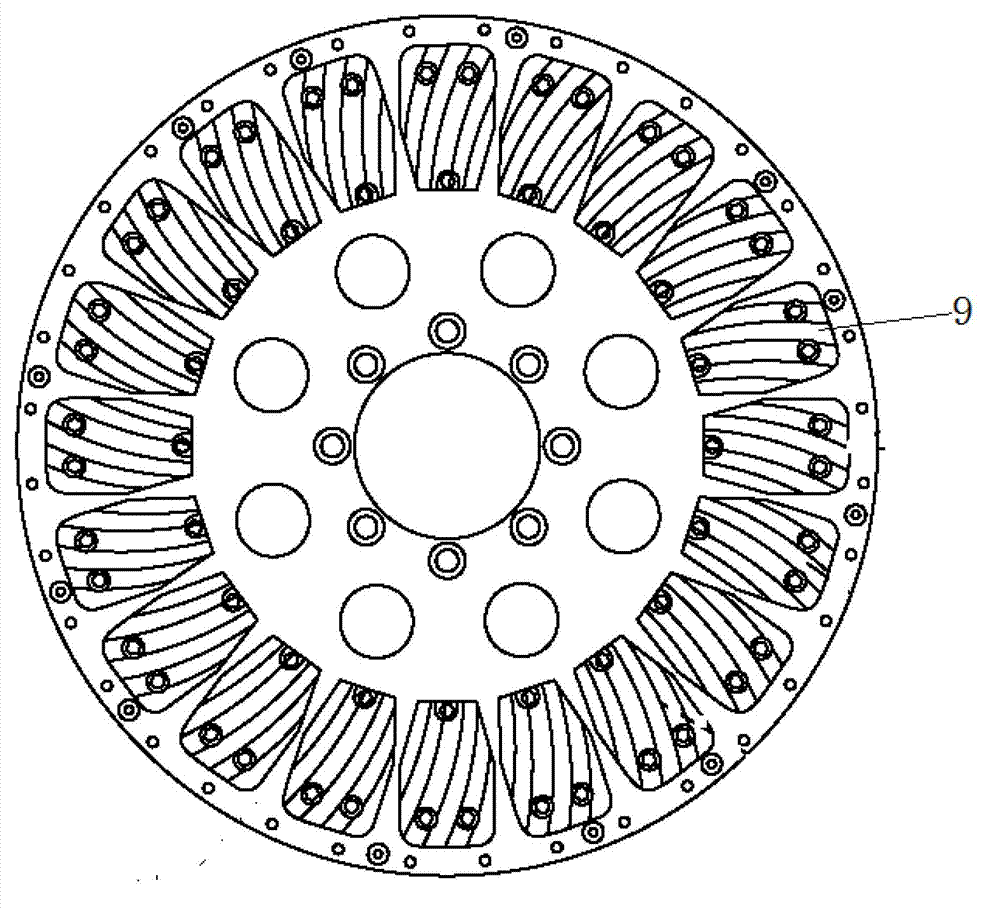

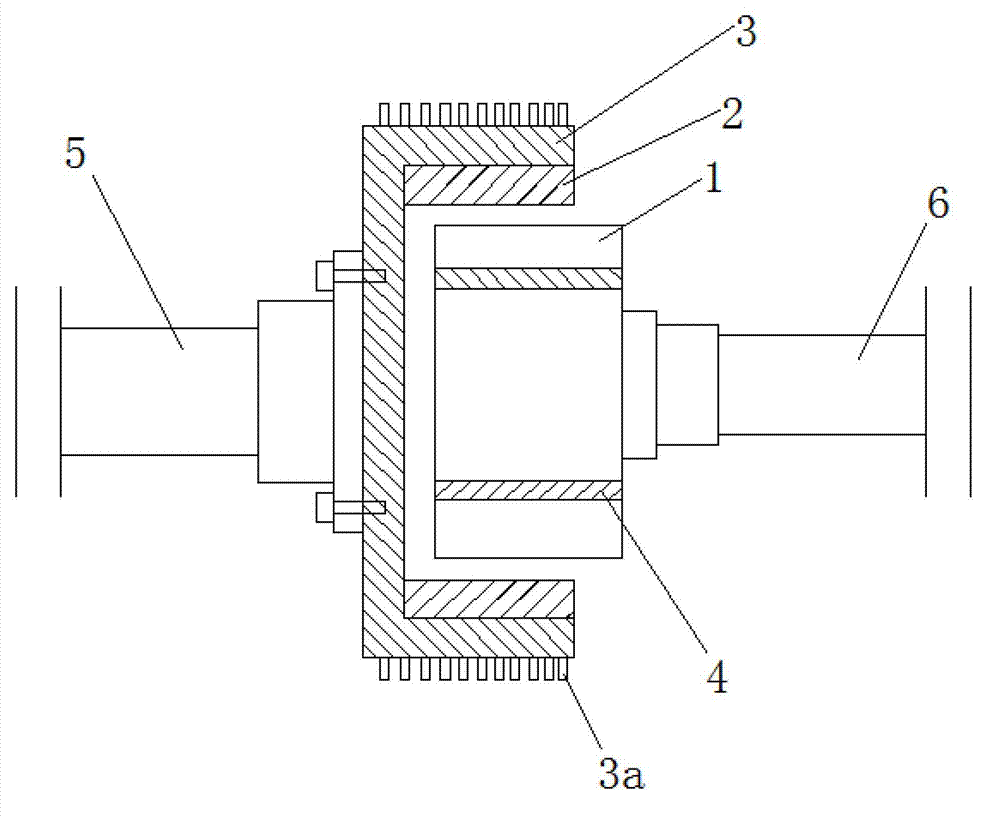

[0020] Such as image 3 As shown, the drive shaft 5, the annular eddy current coupler, and the load shaft 6 are arranged coaxially. The annular coupler includes a first carbon steel ring 3 that plays a supporting role. The axial section of the first carbon steel ring 3 is in a U-shaped structure. The word opening faces to the right, the upper and lower inner walls of the first carbon steel ring 3 are connected to the conductor ring 2, that is, the conductor ring 2 is fixed on the upper and lower inner walls of the first carbon steel ring 3, and the left end of the load shaft 6 is connected to the second carbon steel ring 4 , the permanent magnet ring 1 is fixed on the outside of the second carbon steel ring, and is facing the conductor ring 2. The outer outer surface of the first carbon steel ring 3 is provided with radially arranged cooling fins 3a, and the direction of the cooling fins is parallel to the rotation plane of the first carbon steel ring 3, that is, the direction...

Embodiment ( 2

[0024] On the basis of the first embodiment, the functions of the present invention can also be realized by exchanging the positions of the conductor ring 2 and the permanent magnet ring 1 .

Embodiment ( 3

[0026] On the basis of the first embodiment, after the positions of the drive shaft 5 and the load shaft 6 are reversed, the functions of the present invention can still be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com