Flowmeter and calorimeter asynchronous metering and detecting method and flowmeter and calorimeter asynchronous metering and detecting system based on communication

A technology of measurement and detection and flowmeter, which is applied in the measurement of heat, calorimeter, liquid/fluid solid measurement, etc., can solve the problems that the detection technology cannot meet the detection requirements, does not have high-response pulse signal output, and is difficult to adapt to.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

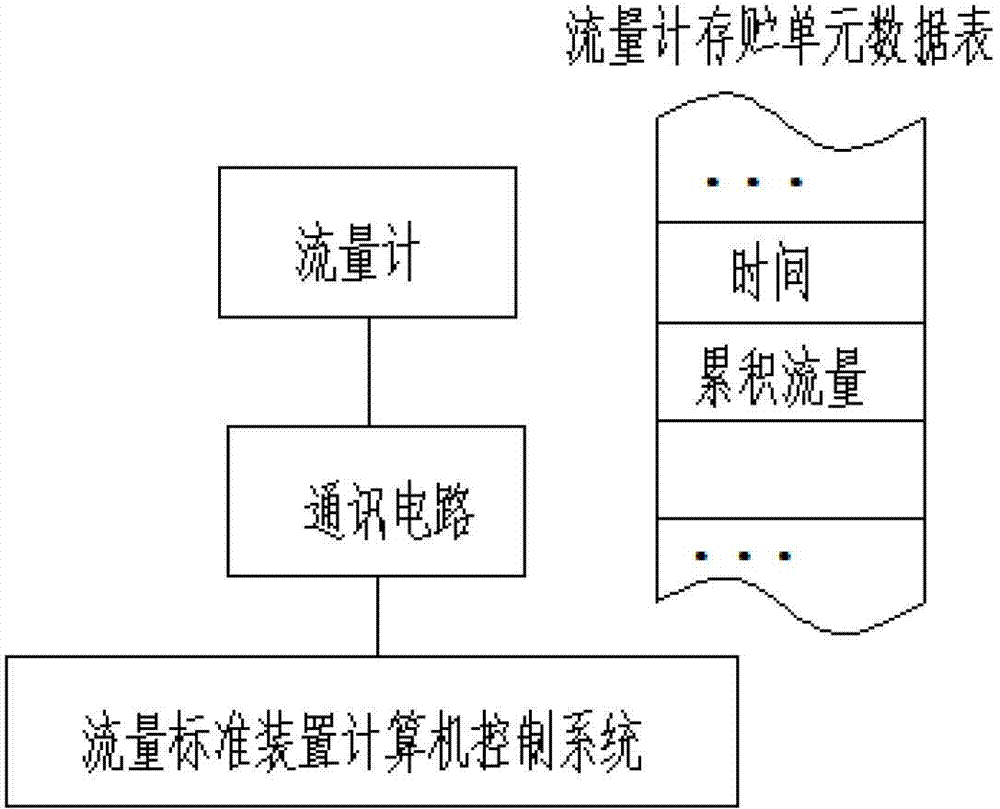

[0036] Reference attached figure 1 .

[0037] The object of this embodiment is a flow meter, and the implementation process is described as follows.

[0038] The communication-based non-synchronized measurement and detection method for flow meters and heat meters of the present invention includes the following steps:

[0039] Step 1. Detect the flow meter and heat meter to be checked, and the microprocessor of the flow and heat signal measured by the sensor is processed by signal and data calculation to obtain the accumulated flow and accumulated heat;

[0040] Step 2: When the microprocessor stores the accumulated flow rate and / or accumulated heat data in the data storage unit, it also stores the time data collected to the internal clock of the microprocessor at this moment in the data storage unit; For flow meters, the cumulative flow and time form a set of one-to-one correspondence data; for heat meters, the cumulative flow, cumulative heat and time form a set of one-to-one corresp...

Embodiment 2

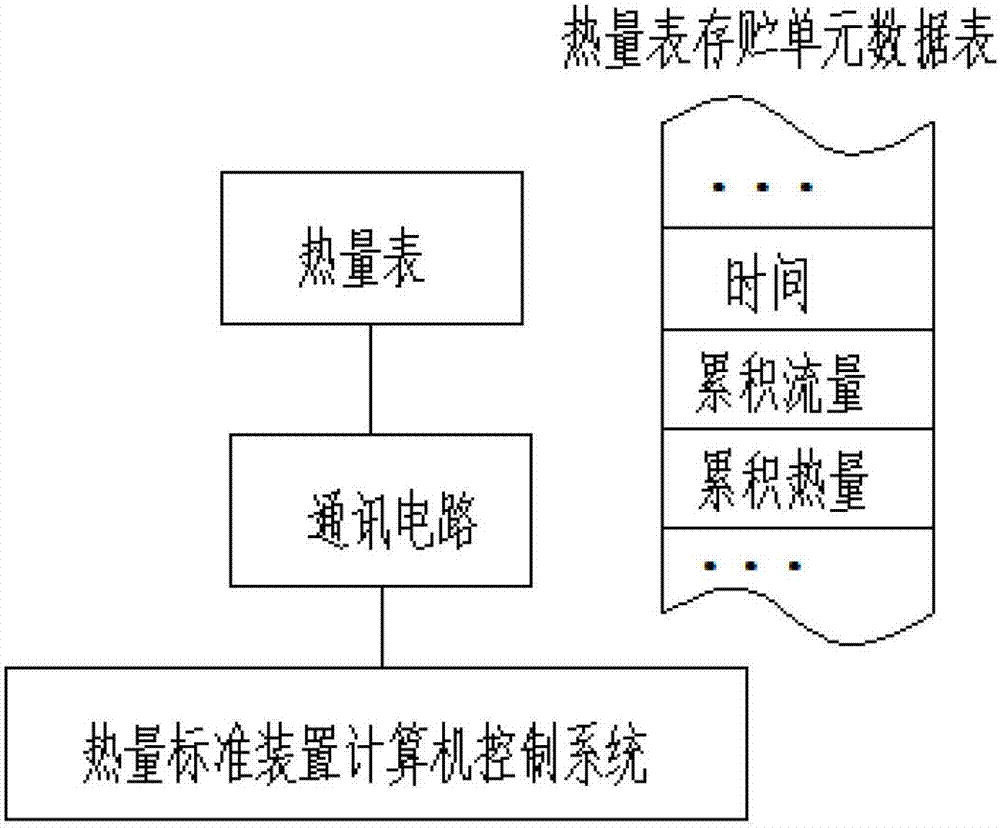

[0048] Reference attached figure 2 .

[0049] The main difference between this embodiment and the first embodiment is that the meter object is different. The meter targeted by this embodiment is a heat meter.

[0050] The implementation process is described as follows.

[0051] The communication-based non-synchronized measurement and detection method for flow meters and heat meters of the present invention includes the following steps:

[0052] Step 1. Detect the flow meter and heat meter to be checked, and the microprocessor of the flow and heat signal measured by the sensor is processed by signal and data calculation to obtain the accumulated flow and accumulated heat;

[0053] Step 2: When the microprocessor stores the accumulated flow rate and / or accumulated heat data in the data storage unit, it also stores the time data collected to the internal clock of the microprocessor at this moment in the data storage unit; For flow meters, the cumulative flow and time form a set of one-t...

Embodiment 3

[0062] This embodiment describes a system using the method of the present invention.

[0063] A communication-based non-synchronized measurement and detection system for flow meters and heat meters, including a standard device computer control system, and sensors for measuring flow signals and heat signals of flow meters and heat meters, characterized in that: the sensors are connected to a microprocessor The microprocessor includes an accumulation unit that accumulates the flow signal and the heat signal to obtain the accumulated flow and accumulated heat, and collects the accumulated flow and accumulated heat with this time from the internal clock of the microprocessor A data storage unit and a communication unit that store time data together; the communication unit is connected to the computer of the standard device computer control system, and the flow rate measurement error E is set in the computer 1 And calorie measurement error E 2 The calculation unit is as follows:

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com