Control method and device for production line processes

A control method and assembly line technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as flexible adjustment and redistribution, and achieve optimal configuration, improve efficiency, and avoid worker confusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

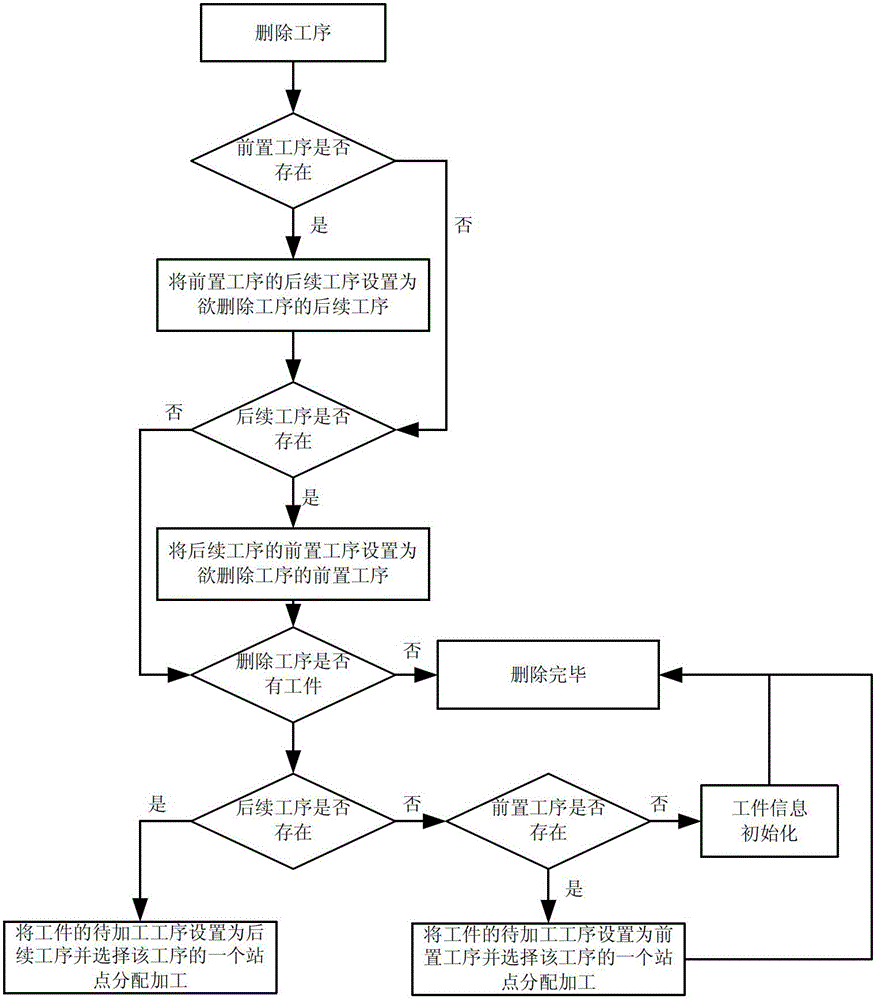

[0044] Specific embodiment 1: In a certain task that includes 10 processing procedures, the process list of the host computer includes the process IDs: A1, A2, ..., A10. When the third process is deleted, the process ID corresponding to A3 will be deleted. process.

[0045] Delete process A3 in the process list, that is, the host computer deletes the process information A3 in the process list, and at the same time updates the information of A2 in the preceding process of A3, sets the subsequent process of A2 as the subsequent process A4 of A3, and sets the preceding process of A4 The process is set as the preceding process A2 of A3. If the station assigned by A3 has no workpieces to be processed, the deletion process ends. If the station assigned by A3 contains workpieces to be processed, obtain the information of these workpieces, and modify the process to be processed of these workpieces to the subsequent process A4 of A3, and select a station from the stations assigned by ...

specific Embodiment 2

[0046] Specific embodiment 2: when the tenth process is deleted, the process whose process ID is A10 is deleted. Since the process A10 is an end process, there is no next process. Therefore, after the host computer deletes process A10 from the process list, it needs to set the subsequent process of process A9 in the process list to empty. For the workpiece whose process to be processed on the assembly line is in A10, modify the process to be processed to the preceding process of A10, that is, process A9, and select a station from the stations allocated for process A9 as the new follow-up processing station. These workpieces are put into the main track for re-running, and re-enter the processing station of process A9, and it is decided by A9 whether to enter a new subsequent process (if A10 is deleted and a new process is added at the end), or to complete (delete A9 No new processes will be added thereafter).

[0047] When the process change of the processing task on the asse...

specific Embodiment 3

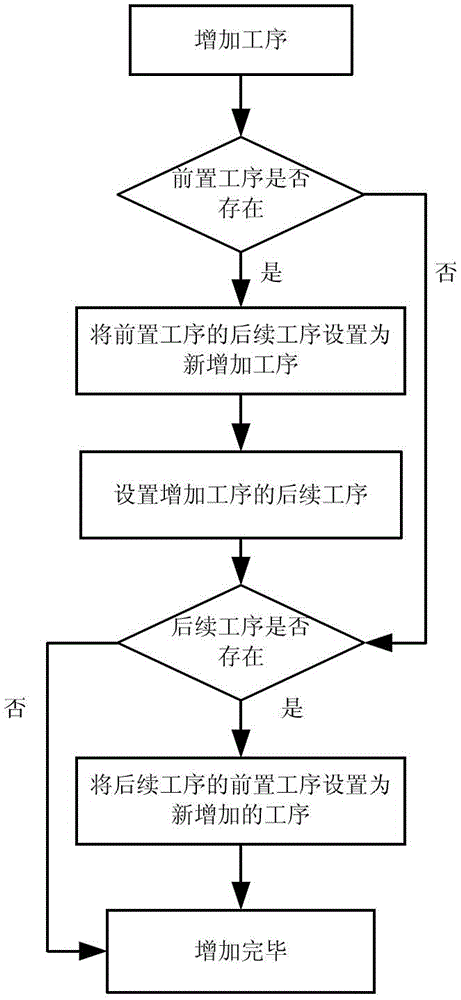

[0049] Specific embodiment three: Adding a new process between the first process and the second process of a processing task can be understood as adding a new process A11 between processes A1 and A2.

[0050] Add a new process A11 in the process list, and the host computer changes the pre-process information of process A11 to A1, and changes the subsequent process to A2. At the same time, the follow-up process of A1 is changed from A2 to A11, and the pre-process of A2 is changed from A1 to A11. When the workpiece whose processing procedure is A1 passes through the export reader-writer of its processing station, the export reader reads the information of the workpiece ID tag and transmits this information to the host computer, and the host computer reads the workpiece ID tag according to the Combined with the updated process list, set the process to be processed of the workpiece as A11, and select the site with the least number of processes to be processed from the sites assign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com