Automatic gas sampling device and using method thereof

An automatic sampling and air extraction device technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of the accuracy of test results, large gas consumption, poor stability of sample injection, etc., and achieve unattended operation , save human resources, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings.

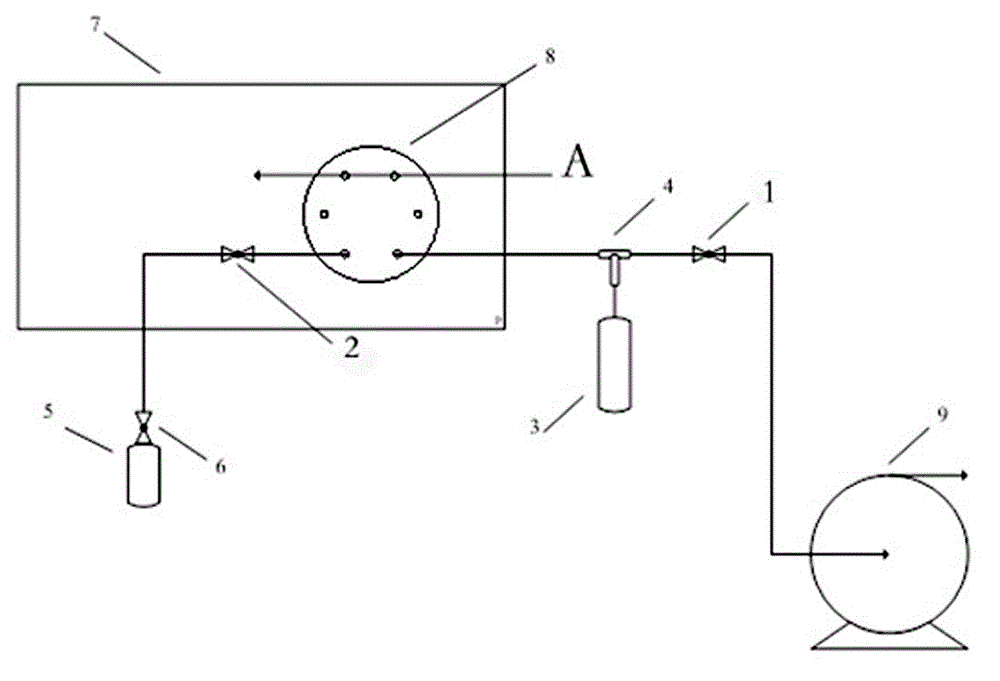

[0023] Such as figure 1 as shown, figure 1 A schematic structural diagram of an air circuit system according to an embodiment of the present invention is shown. An embodiment of the present invention, the negative pressure gas automatic sampling device includes a housing, and the inside of the housing includes a gas circuit system and an electrical circuit system; the structural diagram of the gas circuit system is as follows figure 1 As shown, including a sample analysis instrument 7, the sample analysis instrument of this embodiment is a gas sample analysis instrument, which can be a gas analyzer or a gas detector; as a preferred embodiment, the sample analysis instrument of this embodiment is a gas chromatograph, The gas chromatograph includes a six-way valve 8, one end of the quantitative loop of the six-way valve is connected with the pumping device 9 through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com