Method and device for treating textiles

A textile and treatment agent technology, which is applied in the field of textile treatment devices, can solve the problems of high energy consumption and high cost, and achieve the effects of improving contact, improving heat transfer, and improving energy gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, the invention will be described in terms of slurry coating. In this case the slurry forms the treatment agent. But the invention can be applied in other situations, then for example when the textile is colored or printed or when the textile is simply washed.

[0037] The invention is described next on the basis of textiles in the form of yarn samples. However, it can also be used in other forms of textiles, for example in flat textiles which were previously produced by weaving, knitting, knitting or otherwise.

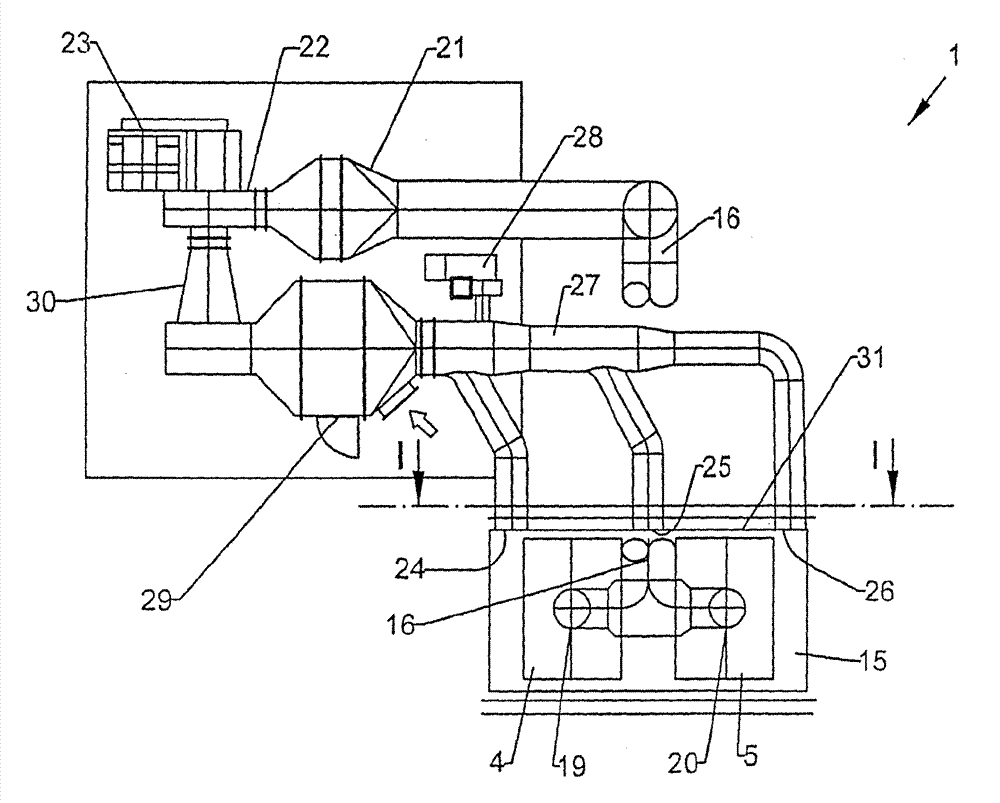

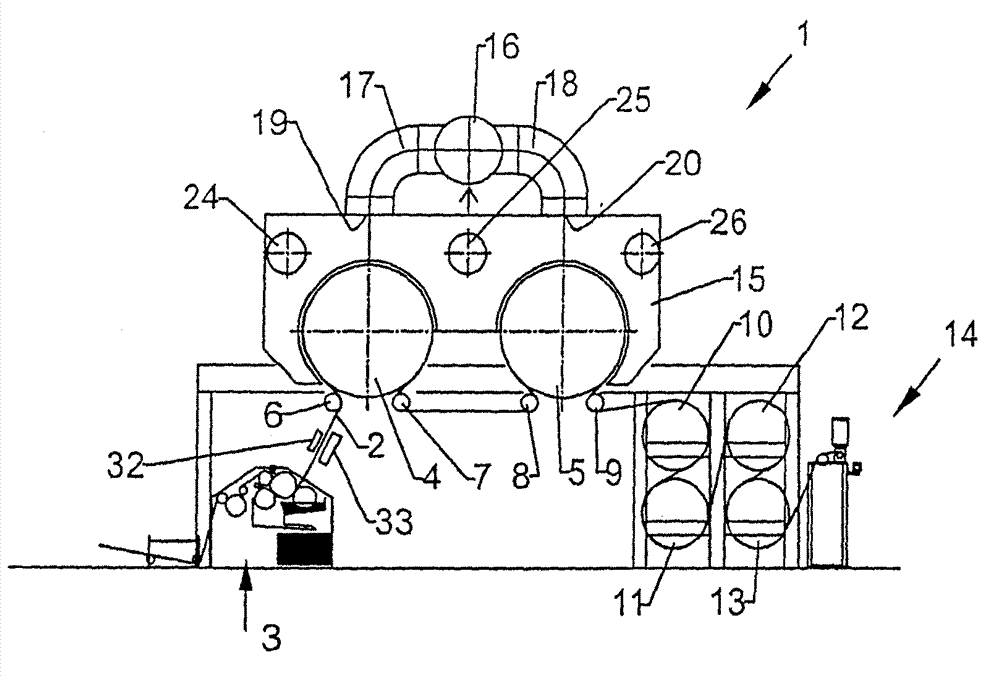

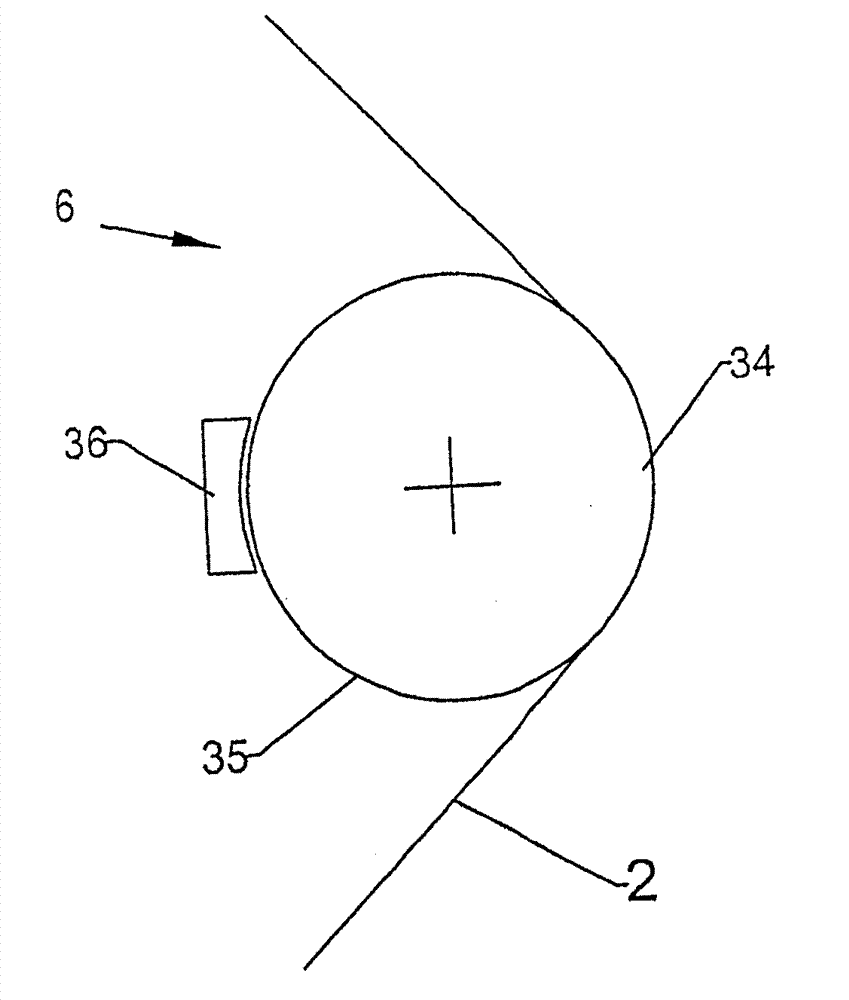

[0038] The device 1 for sizing a textile 2 provided with a yarn sample has a size application section 3 in which the textile 2 is loaded with size. The slurry can have different designs. It can be, for example, a dispersion section in which the slurry is distributed in a carrier fluid. It can also be directly a liquid slurry. Slurries can also be present as foams or pastes. In each case the textile 2 is wet or at least damp when the size is applied. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com