Method for allowing multiple fluid working substances to enter rotating reaction container in insoluble sulphur production

A technology of fluid working medium and reaction vessel is applied in the field of insoluble sulfur production equipment to achieve the effects of reducing labor intensity, improving production efficiency and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

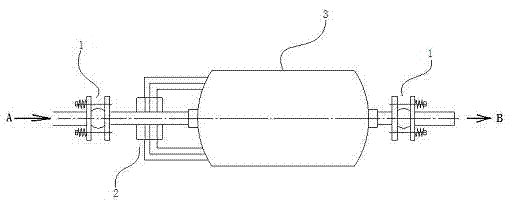

[0012] The specific embodiment of the present invention is as figure 1 shown. This embodiment is carried out in the drying process of insoluble sulfur.

[0013] In the embodiment of the present invention, an external pressure spring type spherical sealing rotary joint is respectively installed on the pipelines at both ends of the insoluble sulfur drying tank; a multi-way rotary joint is installed on the pipeline between one end of the drying tank and the external pressure spring type spherical sealing rotary joint, The number of multi-way channels depends on the type of fluid working medium to be transported; the input and output pipes of the multi-way rotary joint are respectively connected to the corresponding pipe ports of the drying tank compartment. Sulfur, insoluble sulfur and carbon disulfide (CS 2 ) through the pipeline through the external pressure spring type spherical seal rotary joint into the drying tank, and then through the external pressure spring type spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com