LED package with a rounded square lens

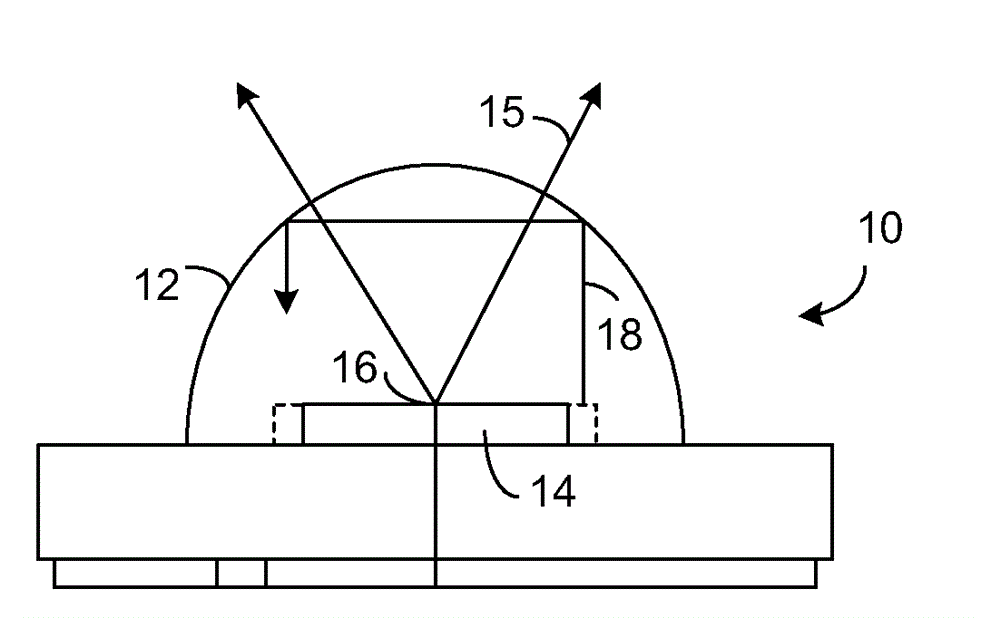

A LED device and lens technology, applied in the field of light-emitting diode (LED) packaging, can solve the problems of not being able to increase the diameter of the hemispherical lens, increase the width of the package 10, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

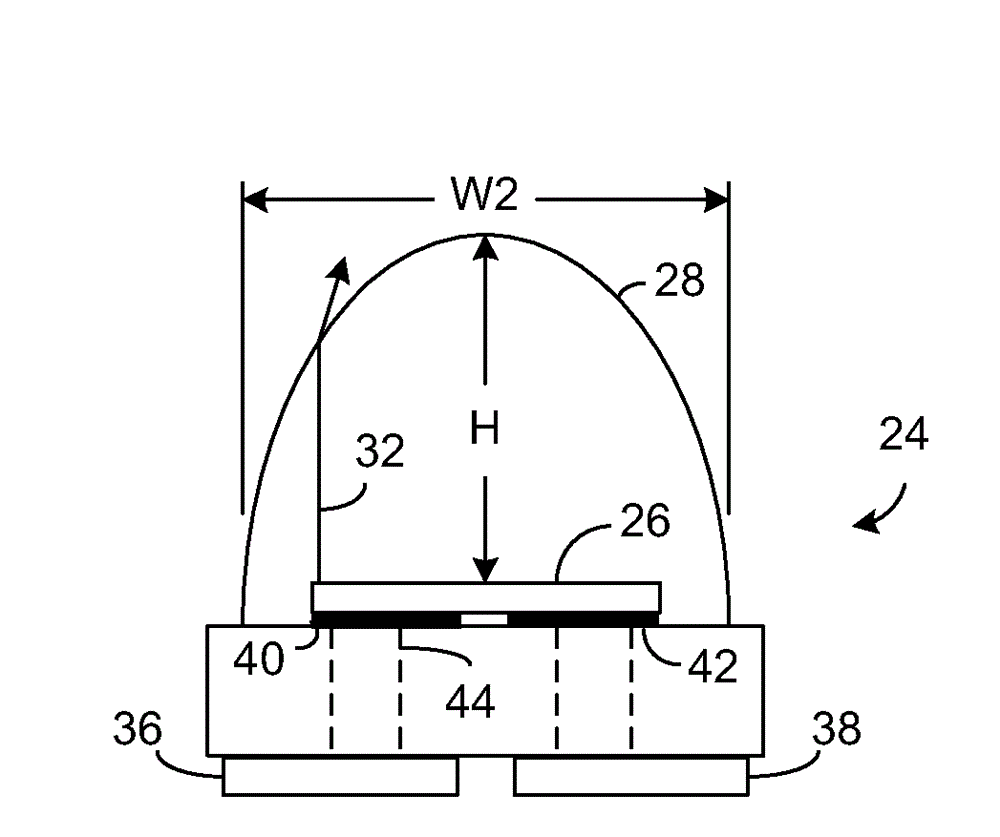

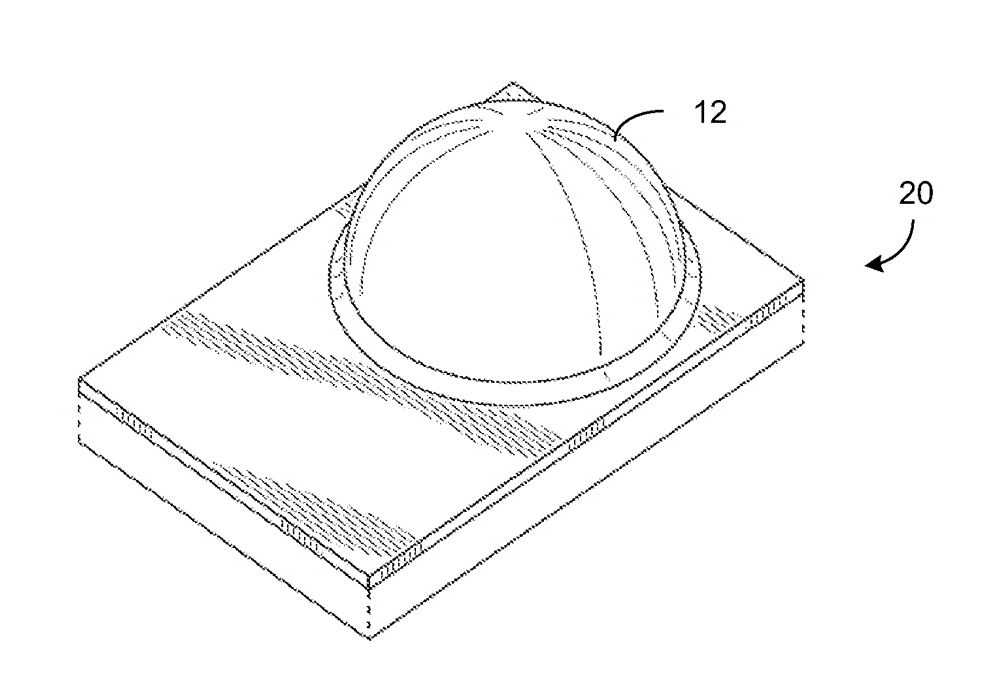

[0026] Figure 5-8 The invention is shown.

[0027] exist Figure 5-7 In this case, the body 22 of the package 24 may be ceramic, plastic, silicone or other material. The outer dimensions of the body 22 can be exactly the same as those of the prior art package 10 or 20, and the electrode structure can be exactly the same, so that the package 24 can be used instead of the package 10 or 20 in any application. The only difference is the size of the LED die 26 and lens 28 . In one example, LED die 26 includes an LED semiconductor layer mounted on a ceramic submount with a metal pattern, and electrodes on the submount are connected to package electrodes, as discussed with reference to FIG. 1 . In another embodiment, LED die 26 does not include a submount.

[0028] In a practical example, the diameter of the prior art hemispherical lens 12 in FIGS. 1 and 4 is about 2.55mm, Figure 5 The width of the rounded square lens 28 is the same size so that it can be used in a package of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com