Lens before edging and method for manufacturing edging lens

A manufacturing method and lens technology, applied in glasses/safety glasses, glasses/goggles, optics, etc., can solve problems such as difficulty in adhesive penetration, achieve the effects of eliminating obstacles to vision, improving transparency, and improving designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, with reference to the drawings, the lens before edging and the method of manufacturing the edging lens will be described. However, the technical scope of the present invention is not limited to these embodiments, and attention should be paid to the contents of the inventions described in the claims and equivalent inventions thereof.

[0045] In addition, hereinafter, the blank lens and the finished lens (or finished lens) are referred to as "lenses before edging", and the lenses obtained by edging the lenses before edging are called edging lenses. In addition, the blank lens, finished lens (or semi-finished lens), and edged lens including the liquid crystal lens structure are collectively referred to as "liquid crystal lens".

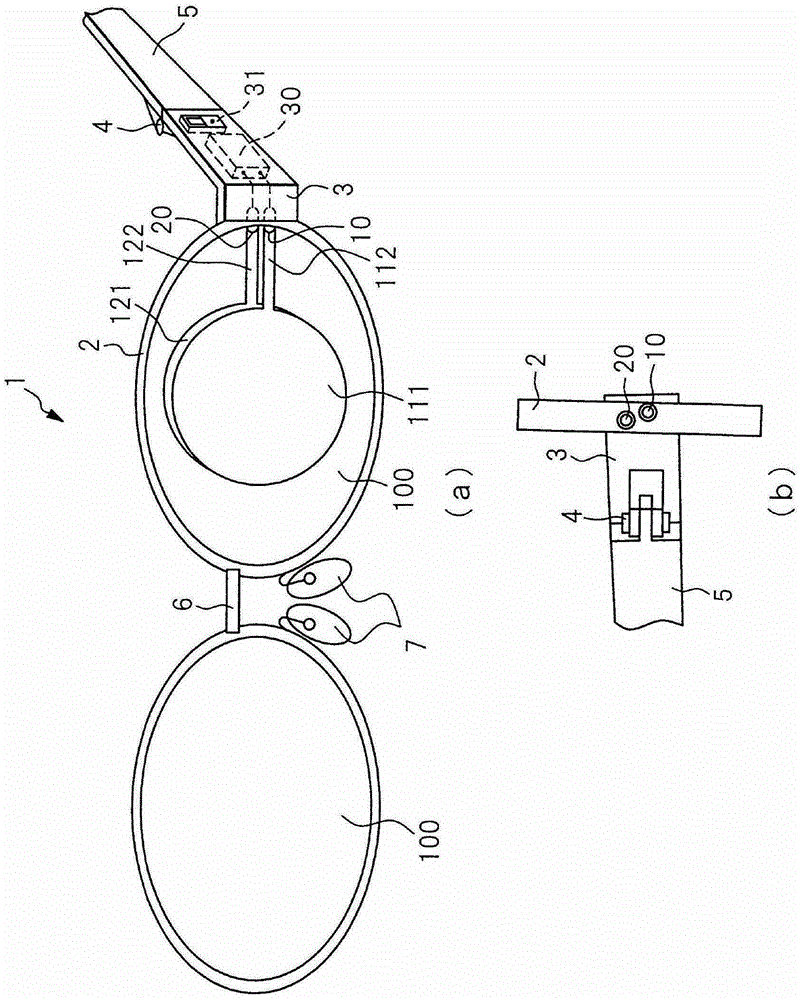

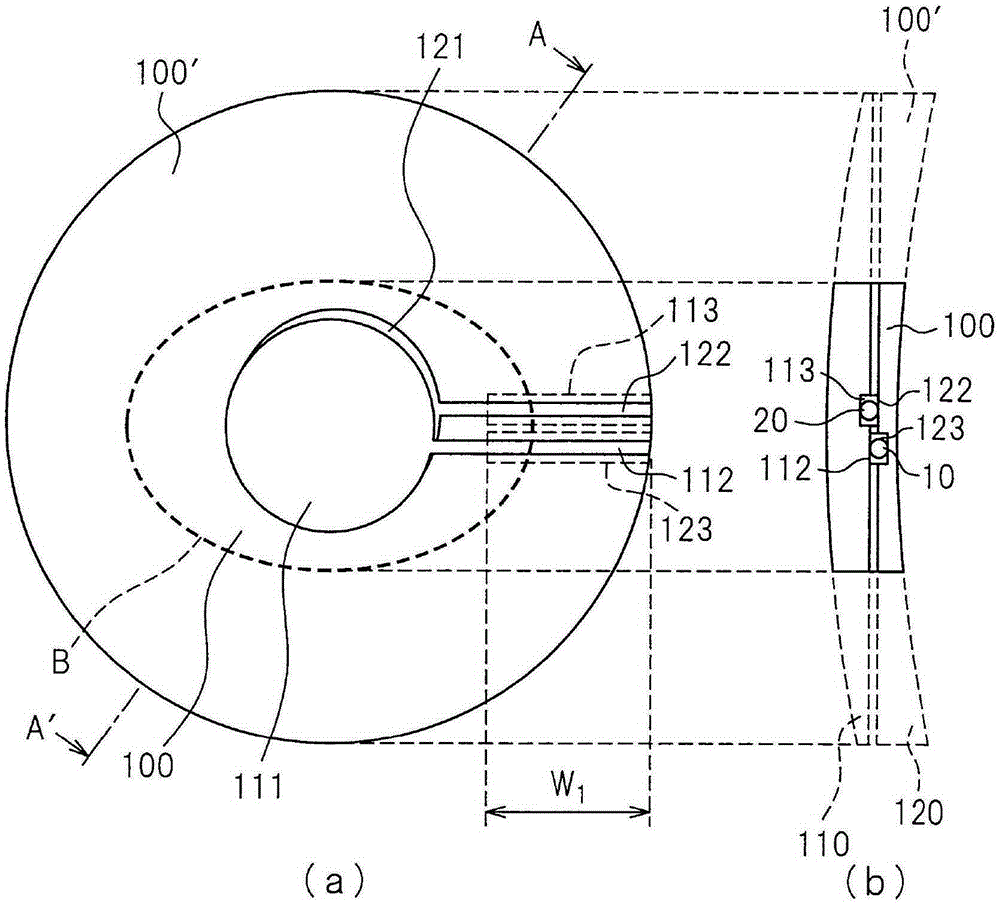

[0046] figure 1 It is a partial schematic view of the electronic glasses 1 using edged lenses as an example.

[0047] Such as figure 1As shown in (a), the electronic glasses 1 include a spectacle frame 2, a stud (ヨロイ) part 3, a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com