Electrified wire-binding insulated spool

A wire insulation and bobbin technology, applied in the field of live construction operation tools, can solve the problems of difficult control of metal wire ends, scratches covered by wire insulation, obvious hand fatigue, etc., to solve scratches, avoid safety hazards, and save money input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

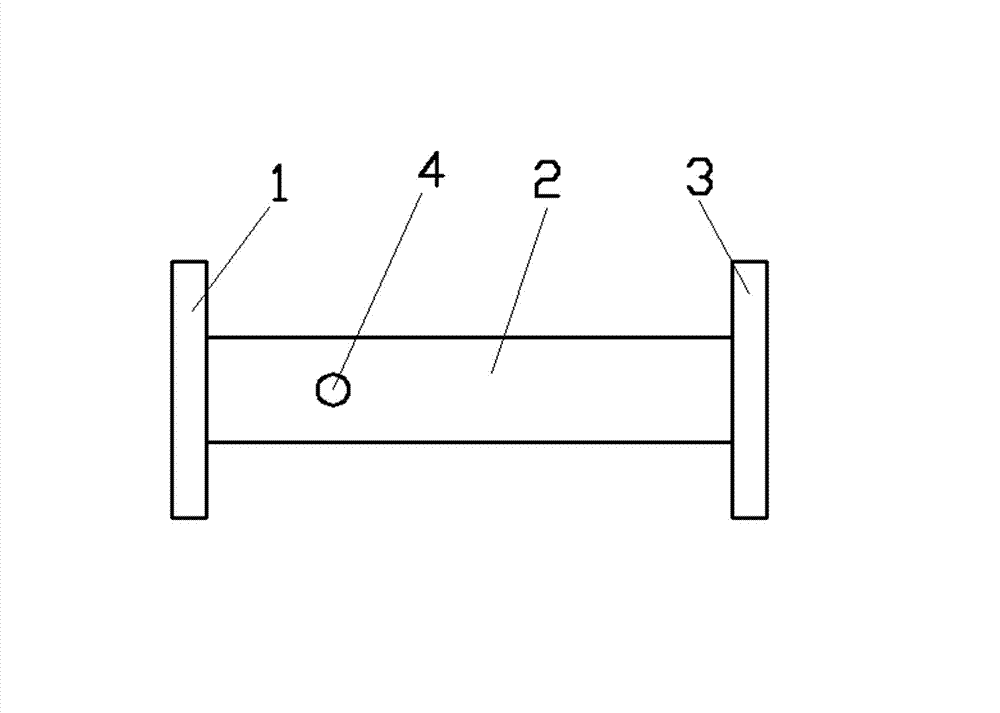

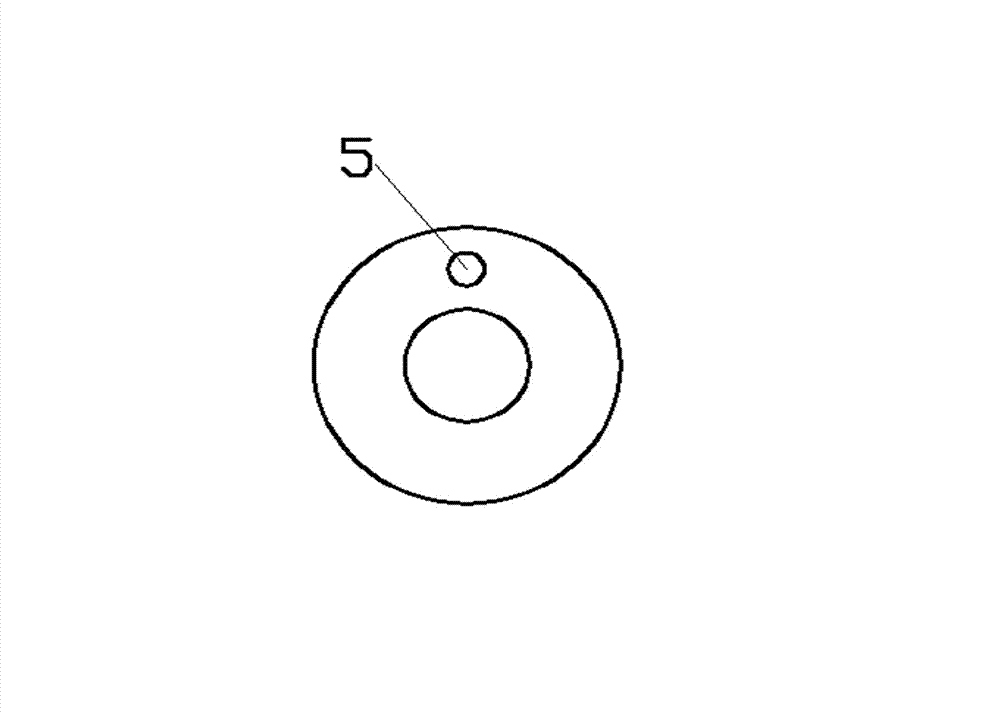

[0018] This embodiment provides an insulated spool for live binding wires, which includes a left end baffle 1, a shaft body 2, a right end baffle 3, a shaft body through hole 4, and a baffle through hole 5. The left end baffle 1, the shaft body 2 and the right end baffle 3 are an integral structure, the shaft through hole 4 is on the shaft 2, the center line of the through hole 4 is perpendicular to the axis of the shaft 2, and the baffle through hole 5 is located On the left end baffle 1 and the right end baffle 3, the center line of the through hole 5 is parallel to the axis of the shaft body 2.

[0019] The end surfaces of the left end baffle 1 and the right end baffle 3 are both circular.

[0020] Specific operation process: First, insert one end of the suitable metal binding wire into the through hole 4 of the shaft body without exposing the end of the metal thread, and then wind the metal binding wire clockwise on the shaft body 2 closely to meet the needs of the work. , The...

Embodiment 2

[0022] The present invention provides an insulated spool for live binding wires, wherein the end surfaces of the left end baffle 1 and the right end baffle 3 are both elliptical, and the purpose is to facilitate placement and prevent rolling. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com