Plug and connector assembly applying same

A plug socket and plug technology, which is applied to the parts of the connection device, electrical components, two-part connection device, etc., can solve problems such as looseness, no anti-drop structure, and disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

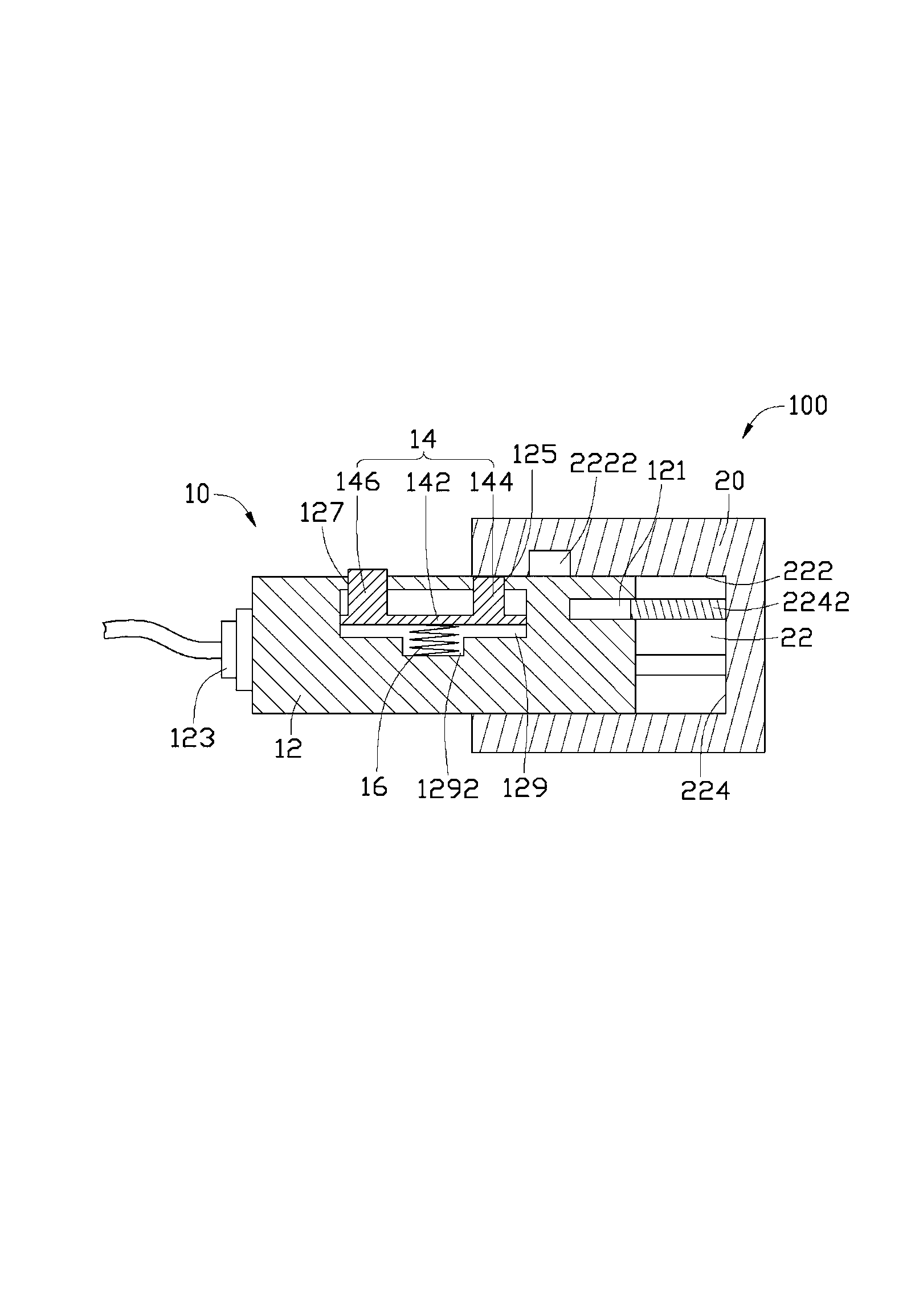

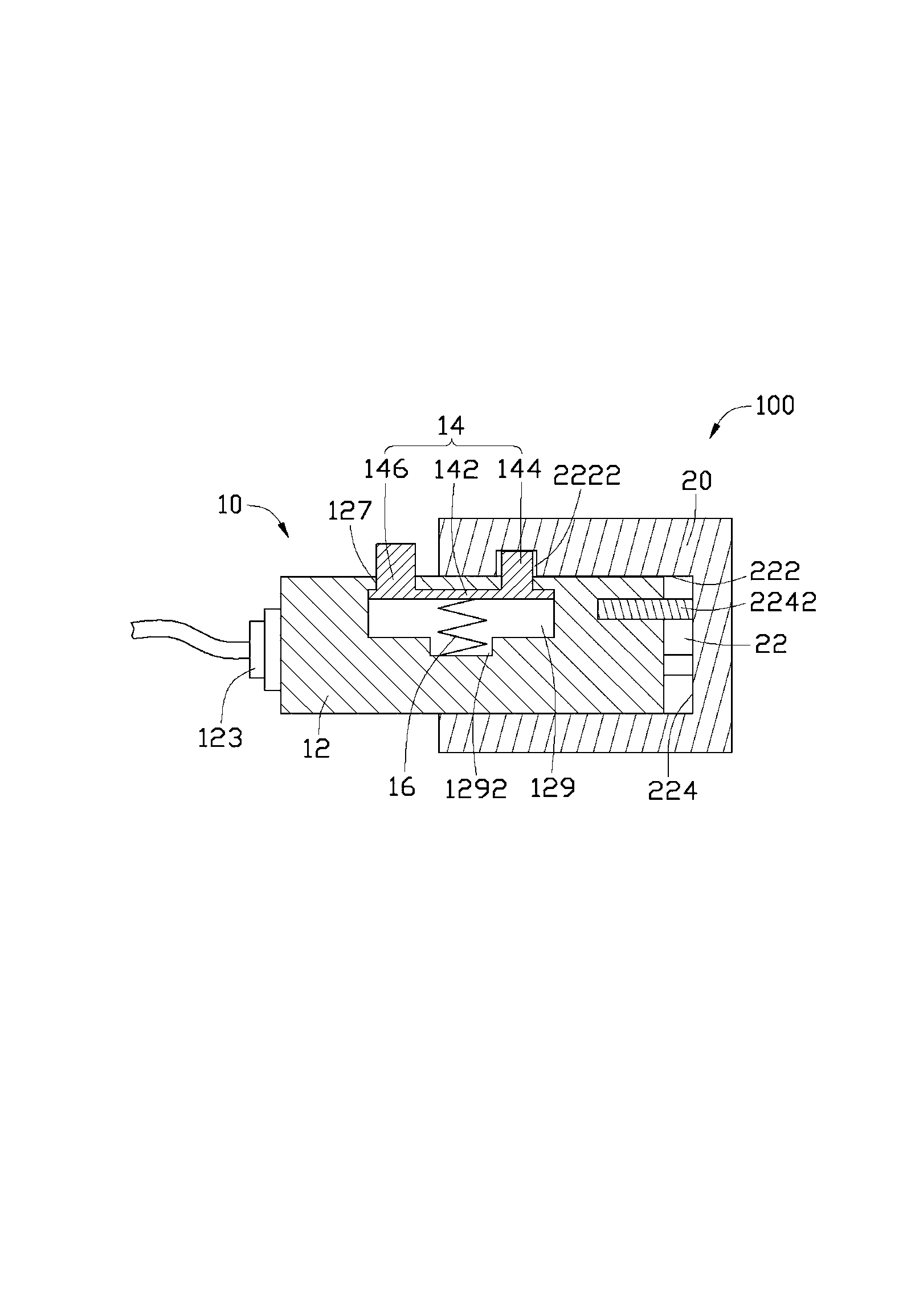

[0013] see figure 1 , the plug socket assembly 100 includes a plug 10 and a socket 20 . The plug 10 includes a main body 12 , an anti-removal component 14 mounted on the main body 12 , and an elastic member 16 elastically abutting against the main body 12 and the anti-detachment component 14 .

[0014] One end of the main body 12 defines a plurality of insertion holes 121 for plugging into the socket 20 , and the other end defines an electrical connection portion 123 for electrically connecting with a power source. A first piercing hole 125 and a second piercing hole 127 are also provided on the peripheral surface of the body 12, and a housing cavity 129 communicating with the first piercing hole 125 and the second piercing hole 127 is also provided in the body 12 . The accommodating cavity 129 is used for accommodating the anti-off component 14 and the elastic component 16 . The first through hole 125 and the second through hole 127 are used to partially protrude the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com