Aeration pump

A technology of aeration pump and air guide shaft, which is applied in water aeration, pump, pump device, etc., can solve the problems of the air volume and strength of the sieve is not very large, the efficiency is not very ideal, and the path is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

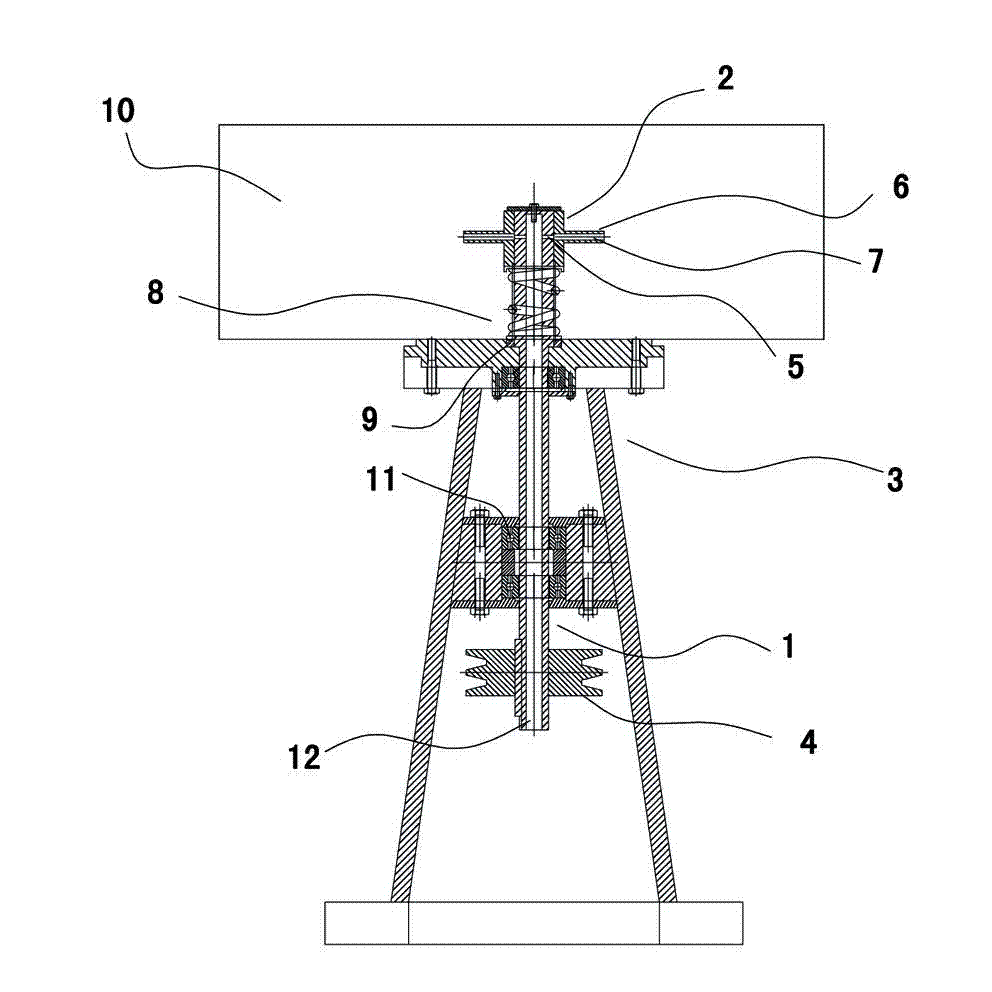

[0014] Please refer to image 3 , the aeration pump in the figure includes a rotary drive device, a hollow wind guide shaft 1, an impeller 2 communicating with the hollow wind guide shaft inner cavity 12, a sealing assembly, and a bracket 3 supporting the above-mentioned components.

[0015] Rotary driving device comprises motor, transmission belt, transmission wheel 4, and wherein motor and transmission belt are not shown in the figure;

[0016] The wind guide shaft 1 is a straight shaft, the inside is empty for outside air to flow in, and the top end is processed with a transverse cavity 5 communicating with the blade cavity 7 of the impeller 2 .

[0017] The impeller 2 includes a hollow inner cavity and a hollow blade 6; the hollow inner cavity is used for installing the wind guide shaft 1, and the blade inner cavity 7 is also hollow and communicates with the transverse cavity 5 of the wind guide shaft 1, and the blade inner cavity 7 forms a height difference with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com