Low-cost smelting silicon-controlling method for hydro-chrome-molybdenum steel

A chromium-molybdenum steel, low-cost technology, applied in the field of low-cost hydrogen chromium-molybdenum steel smelting silicon control, can solve the problems of high silicon sampling at the end of vacuum, affecting contract delivery time, weakening market advantages, etc., to achieve silicon increase Reduce, shorten the effect of strong reduction time, good slag fluidity and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

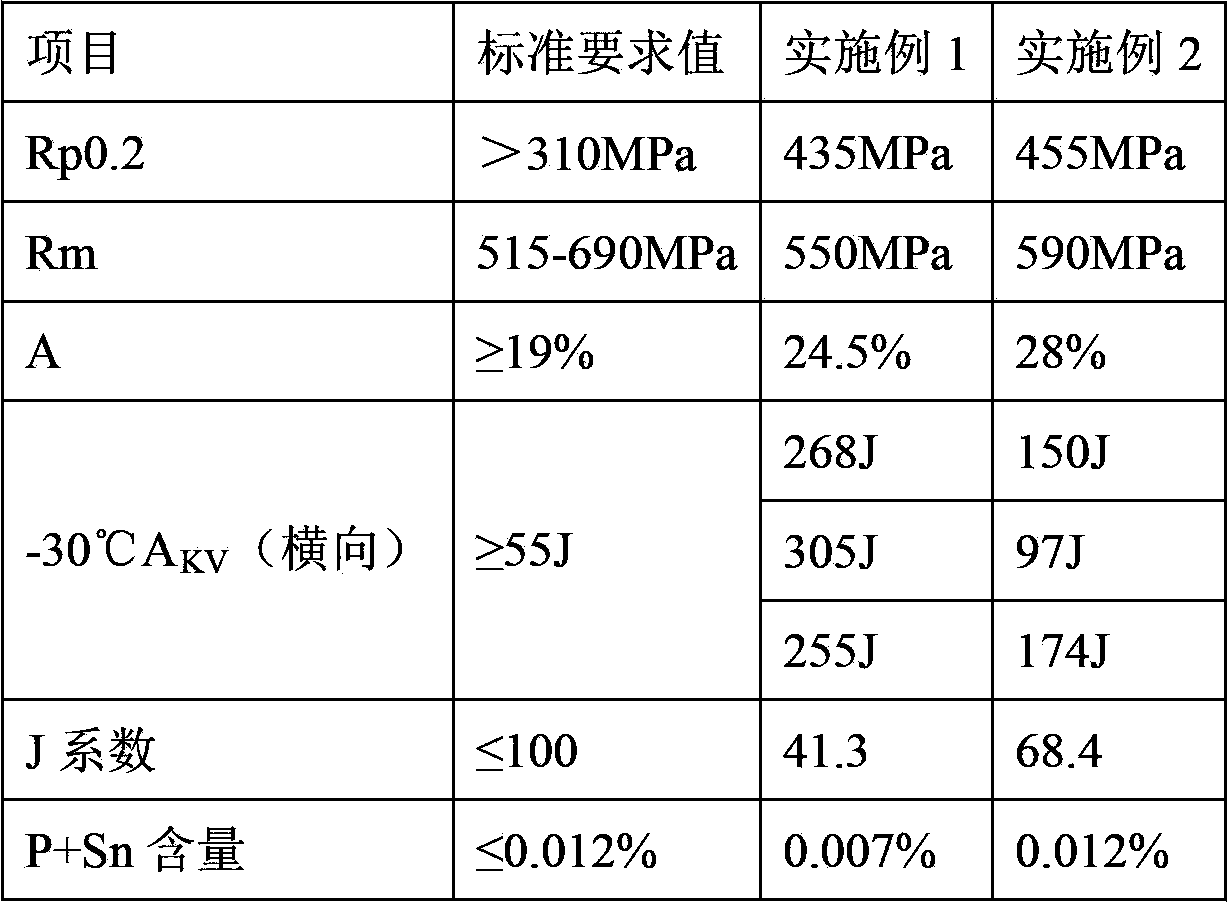

Embodiment 1

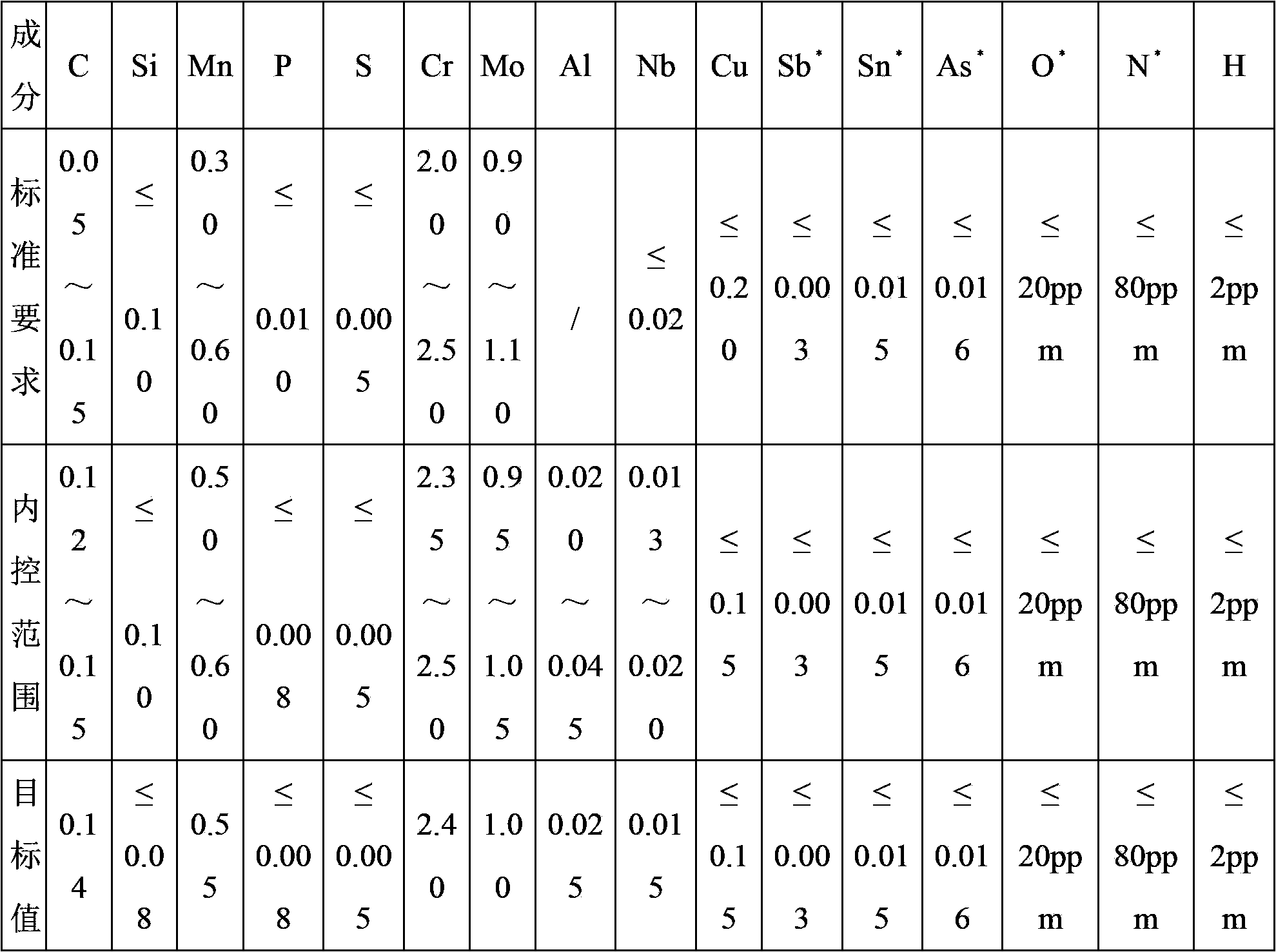

[0018] The silicon-control technology method for smelting low-cost hydrogen-prone chromium-molybdenum steel (100 tons of molten steel / furnace) in this embodiment, the specific steps are as follows:

[0019] (1) Electric furnace smelting: the proportion of pig iron and iron is not less than 70wt%, and the amount of scrap steel added is less than 30% of the total material; It is strictly forbidden to add any deoxidizer and alloy during the process, and the large package sample [P] ≤ 0.005% of the electric furnace;

[0020] (2) LF refining: 200m of aluminum wire is fed into the refining seat for the first time to strengthen the deoxidation effect of LF in the early stage. After refining and power transmission for 13 minutes, 500kg of carbon powder, 300kg of calcium carbide, and 250kg of aluminum particles are used as diffusion deoxidizers. Yellowish white, to prevent raw materials from increasing silicon in molten steel; add 3000kg of lime and fluorite to make slag during the ref...

Embodiment 2

[0024] The silicon-control technology method for smelting low-cost hydrogen-prone chromium-molybdenum steel (100 tons of molten steel / furnace) in this embodiment, the specific steps are as follows:

[0025] (1) Electric furnace smelting: the proportion of pig iron and iron is not less than 70wt%, and the amount of scrap steel added is less than 30% of the total material; the temperature in the electric furnace for tapping is controlled at 1580°C to ensure that there is no cold material in the furnace, and the steel is tapped It is strictly forbidden to add any deoxidizer and alloy during the process, and the large package sample [P] ≤ 0.005% of the electric furnace;

[0026] (2) LF refining: 200m of aluminum wire is fed into the refining seat for the first time to strengthen the deoxidation effect of LF in the early stage. After refining and power transmission for 15 minutes, 500kg of carbon powder, 300kg of calcium carbide, and 250kg of aluminum particles are used as diffusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com