Dual-clutch group transmission, and method for actuating a dual-clutch group transmission

一种双离合器、变速器的技术,应用在车辆变速箱、运输和包装、带有齿的元件等方向,能够解决变速器主轴支承很难、范围选择档组不能进行负载转换、范围转换没有得到牵引力支持等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

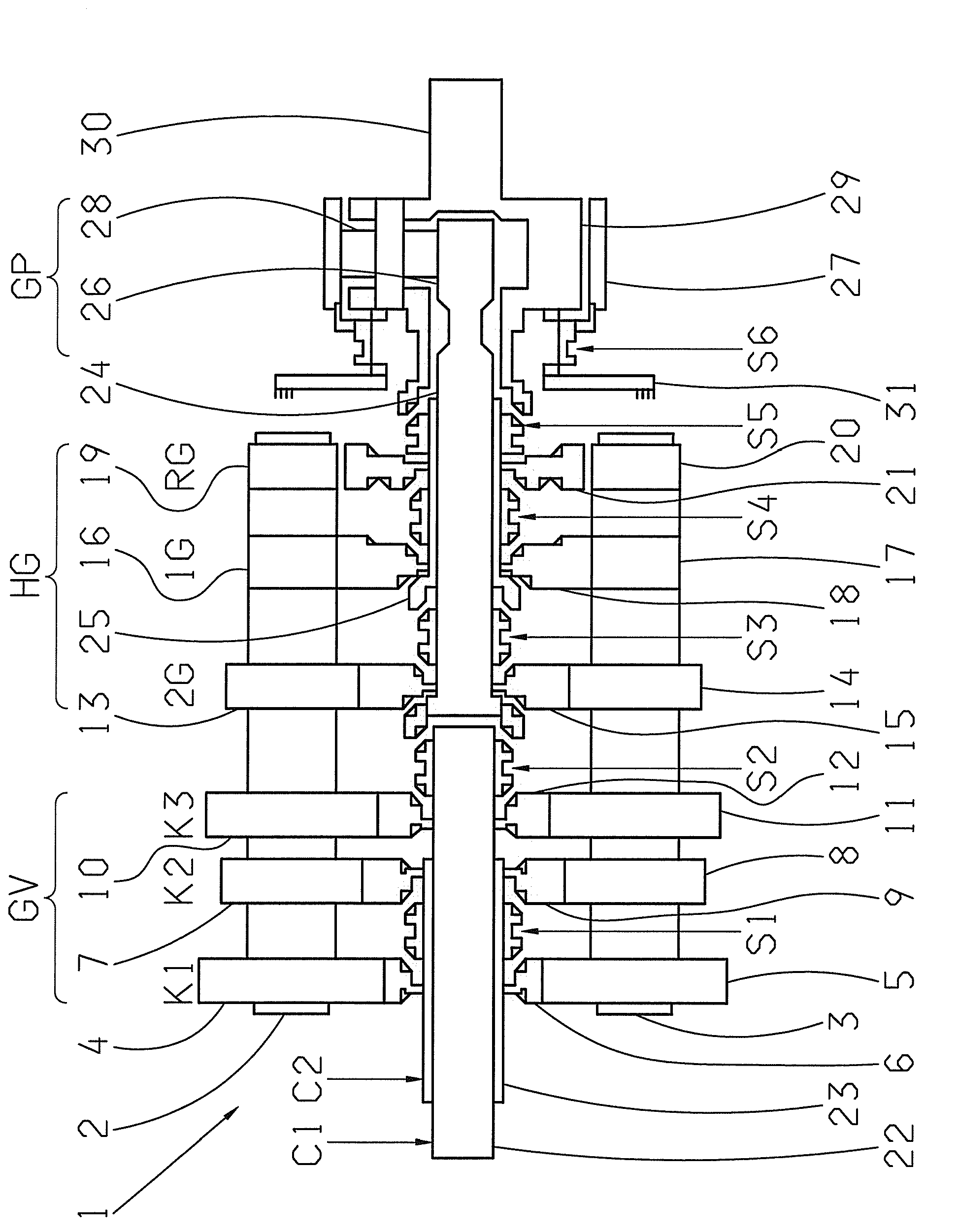

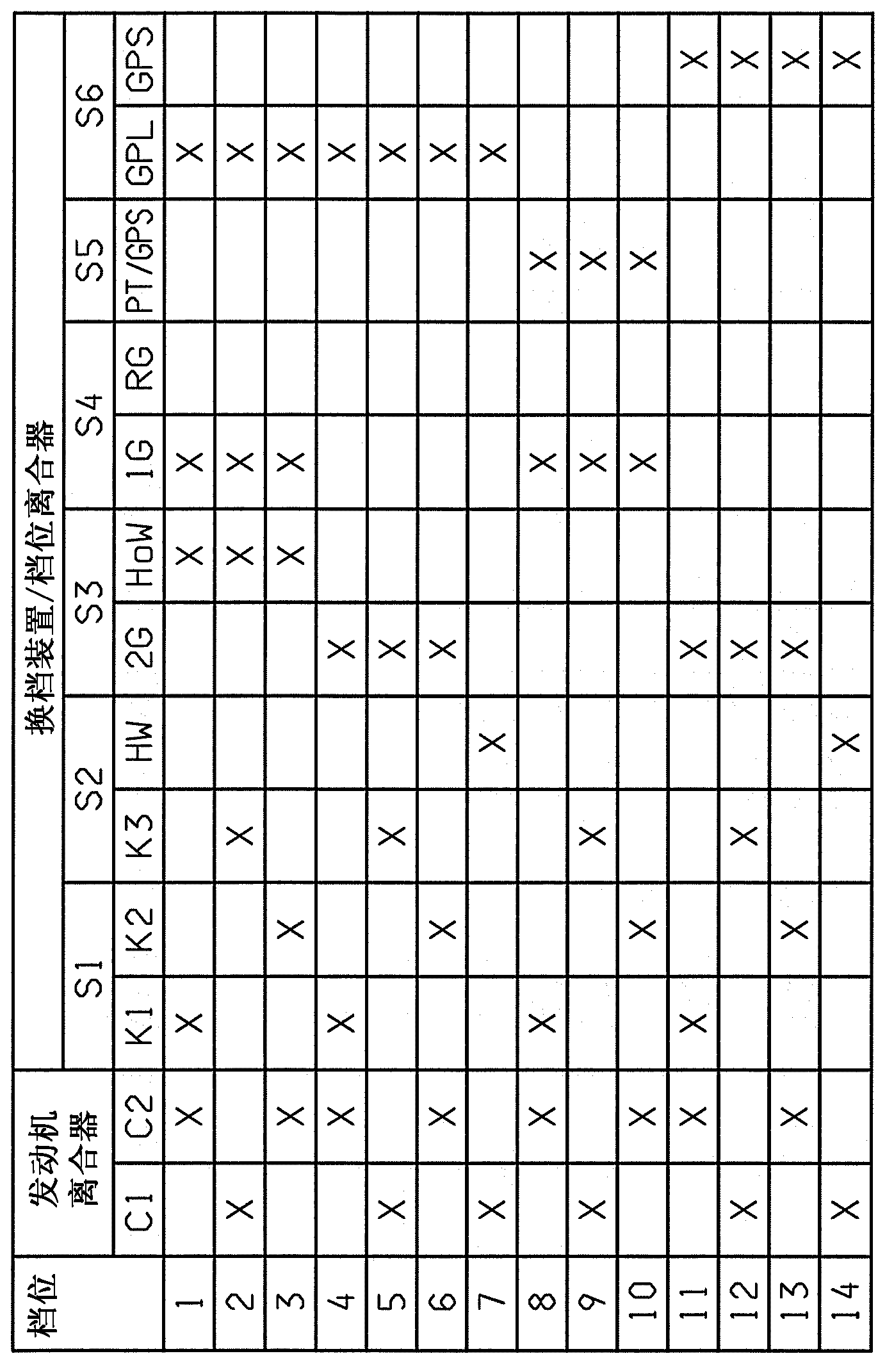

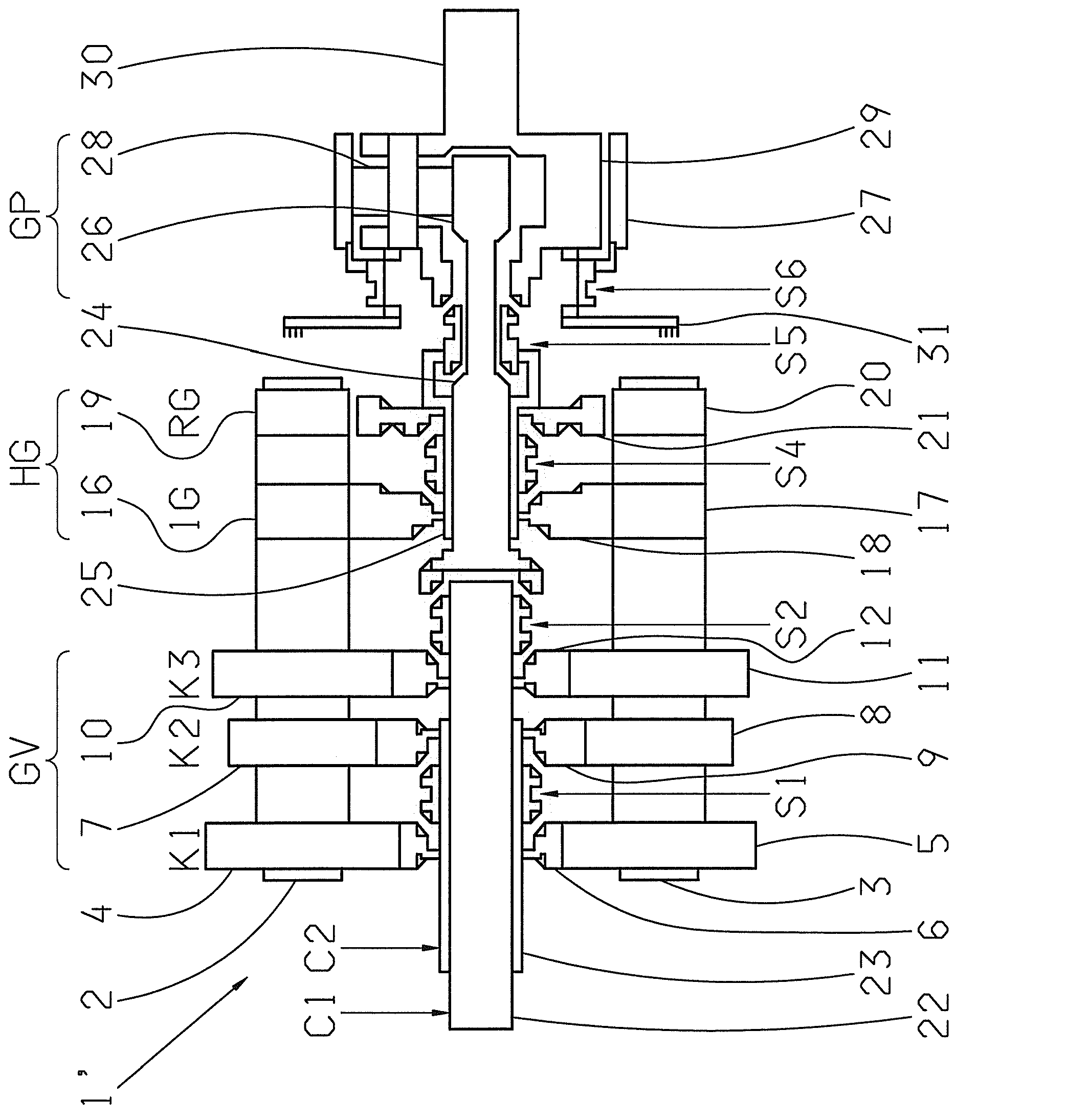

[0031] Thus, in figure 1 A schematic diagram of a first transmission configuration 1 of a dual clutch group transmission is shown in , as may be provided for example for a truck. The transmission arrangement 1 includes three transmission gear groups GV, HG, GP. Input side split gear group GV with three input constant transmission stages K1, K2, K3, main gear group HG with first gear 1G, second gear 2G and reverse gear RG, with lower gear range GPL The range selection gear group GP of the upper gear range GPS is arranged axially one after the other.

[0032] The splitter group GV and the main gear group HG are formed as a countershaft transmission with two common countershafts 2 , 3 with parallel axes. Gear constant transmission stages K1, K2, K3 and gears 2G, 1G, RG are formed with two fixed wheels each 4, 5; 7, 8; 10, 11; 13, 14; 16, 17; 19, 20 and Each of a gear set of idler wheels 6, 9, 12, 15, 18 and 21, said fixed wheels 4, 5; 7, 8; 10, 11; 13, 14; 16, 17; 19, 20 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com