Screed plate frame and screed plate and paver

A screed frame and screed technology, which is applied in the fields of screed frame, screed and paver, can solve the problems of easy torsion and deformation of the screed frame, and achieve the effects of saving production cost, simple structure and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 12

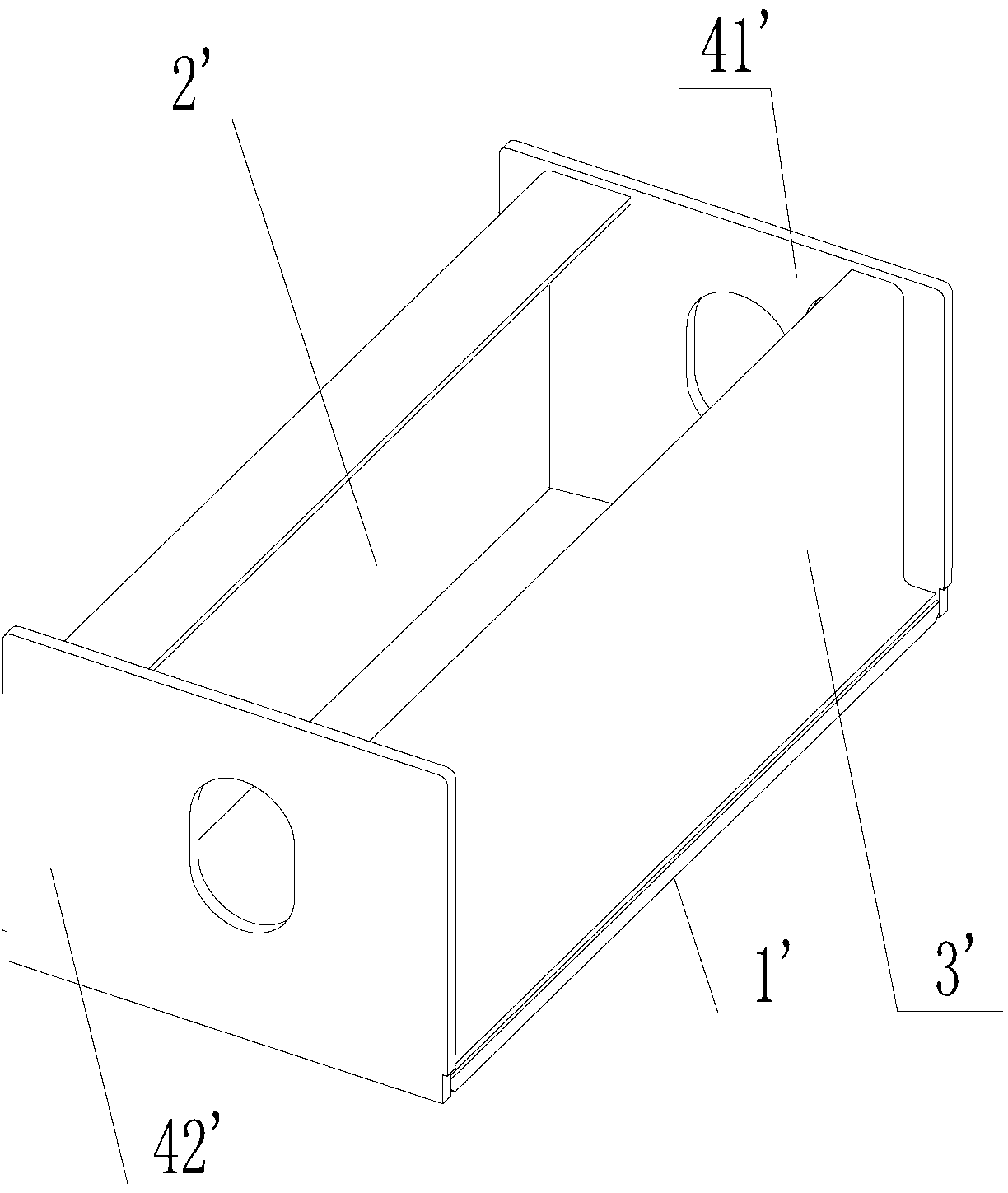

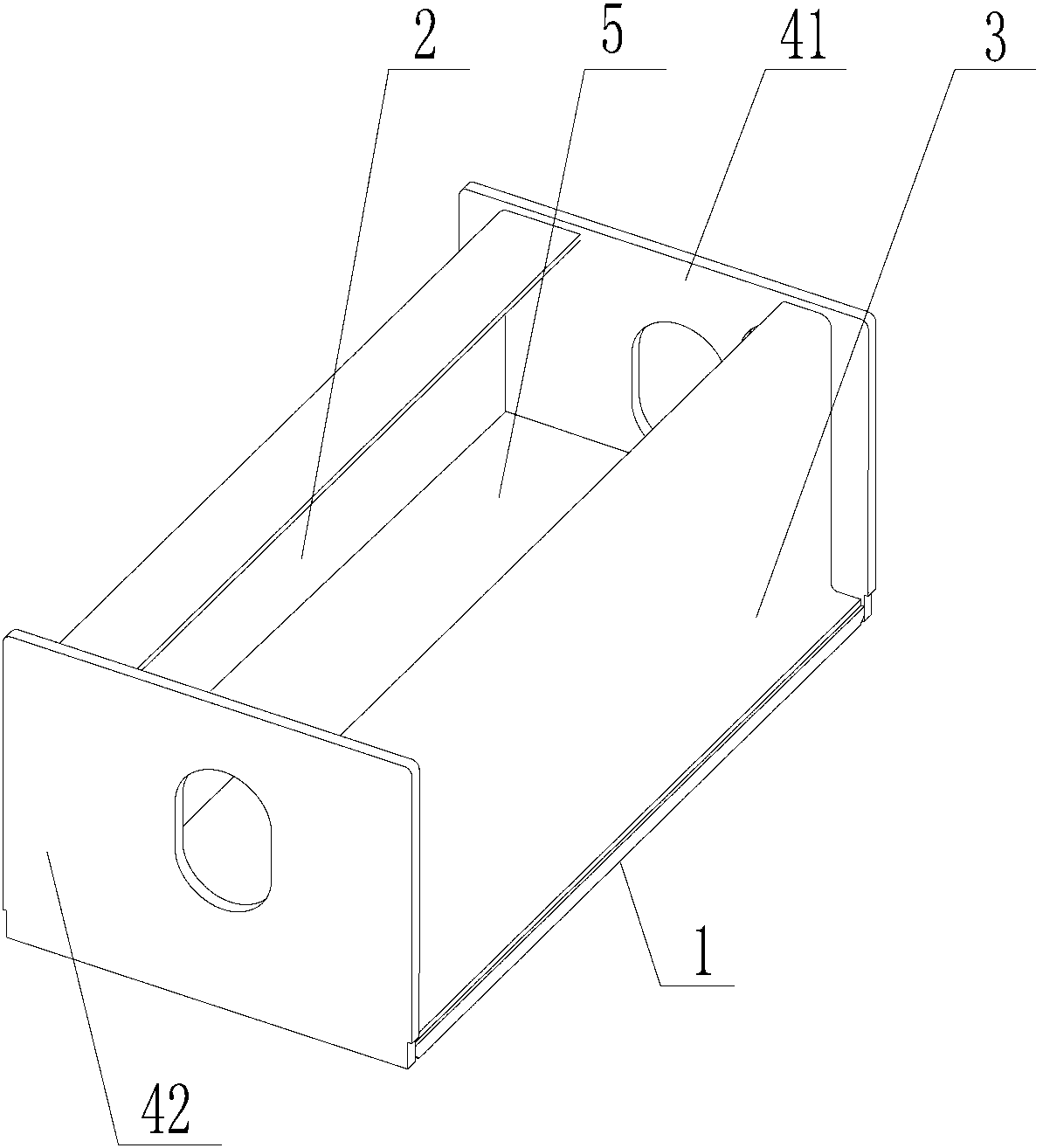

[0063] Above-mentioned 12 embodiments provide the same structure of screed frame, see Figure 3 to Figure 4 , which both include:

[0064] The base plate 1 and the partition plate 5 arranged horizontally, the front plate 2, the rear plate 3, the first side plate 41 and the second side plate 42 arranged vertically, wherein, the base plate 1, the front plate 2, the rear plate 3, the first side The plate 41 and the second side plate 42 form a cuboid structure whose top is not closed;

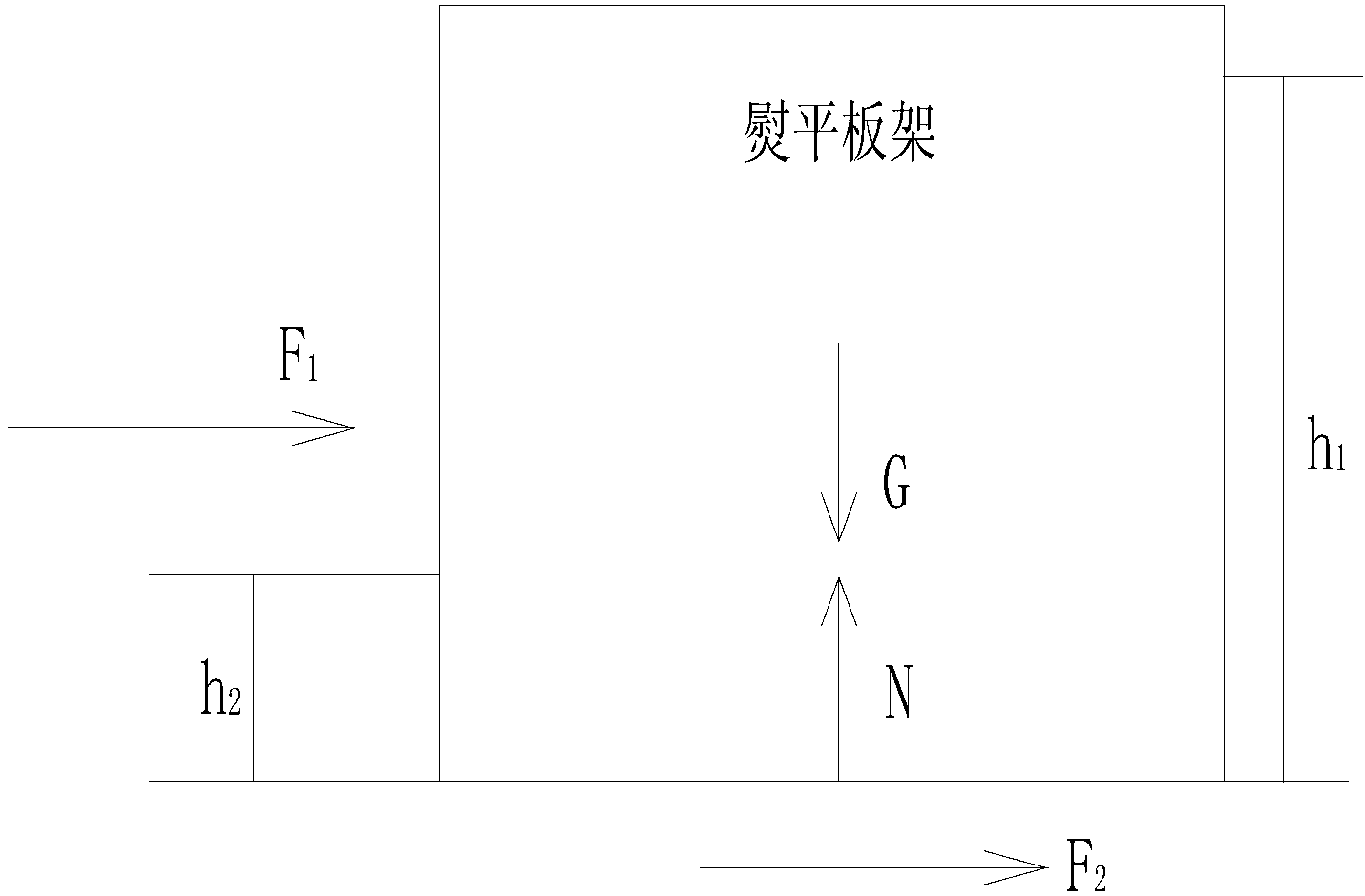

[0065] The specific specifications of the screed frame provided by the above-mentioned 12 embodiments are listed in Table 1. in FIG. 1:

[0066] The height of the screed frame is: the vertical distance between the top surface of the front plate or the rear plate and the bottom surface of the bottom plate;

[0067] The length of the screed frame is: the length of the bottom plate;

[0068] The height of the partition is: the vertical distance from the center line of the partition along the horiz...

Embodiment 13~15

[0072] The above-mentioned 3 embodiments provide the same structure of the screed frame, please refer to for details Figure 5 , which differs from Embodiments 1 to 12 in that: the number of separators is 2.

[0073] The specific specifications of the screed frame provided in Examples 13 to 15 are listed in Table 2. The height of the partition in Table 2 is: the vertical distance from the top surface of the first partition to the bottom surface of the second partition arranged in the vertical direction. The distance from the midpoint of the distance to the bottom surface of the slab.

[0074] Table 2 Specific specifications of the screed frame provided by Examples 13 to 15

[0075]

Embodiment 16~18

[0077] The above-mentioned 3 embodiments provide the same structure of the screed frame, please refer to for details Figure 6 and Figure 7 , and its difference from Embodiments 1 to 12 is that it is provided with two vertical reinforcement plates, and the specific specifications of the screed frame provided by Embodiments 16 to 18 are listed in Table 3:

[0078] Table 3 Specific specifications of the screed frame provided by Examples 16-18

[0079]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com