Marshall design method for evotherm warm mix asphalt mixture

A technology of asphalt mixture and warm-mix asphalt, which is applied in the field of materials, can solve the problems that the Marshall design method cannot be compacted, and achieve the effects of overcoming the inability to design warm-mix asphalt mixture, perfecting the design method, and accurate compaction degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A Marshall design method of Evotherm warm mix asphalt mixture, it comprises the following steps:

[0015] (1) Use the Marshall method of hot mix asphalt mixture to design the gradation and asphalt ratio of warm mix, such as the asphalt ratio is determined to be 5.2%;

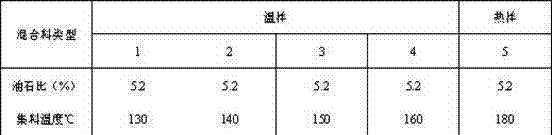

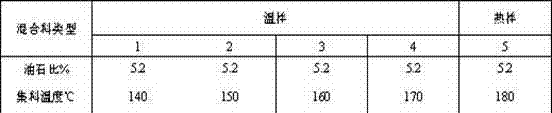

[0016]

[0017] (2) If SBS modified AC-13 asphalt mixture is selected, the asphalt temperature remains unchanged at 165°C, and the aggregate temperature is adjusted at 130-180°C to conduct rutting plate tests, taking the bulk density of the specimen of the hot mix mixture as the standard , to determine the aggregate temperature and compaction temperature of warm mix asphalt mixture;

[0018]

[0019] (3) Carry out the high temperature, low temperature and water stability tests of the warm mix mixture with the aggregate temperature and compaction temperature in step (2), and evaluate the technical indicators of the hot mix mixture, so as to design the Evotherm warm mix asphalt mixture material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com