Electric control system of isothermal die-forging hydraulic machine

An electronic control system and isothermal die forging technology, applied in the driving device of the forging press, etc., can solve the problems of signal distortion, increase the complexity of wiring layout, loss, etc., to simplify the wiring layout, facilitate the transmission and processing process, and improve efficiency. and the effect of processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

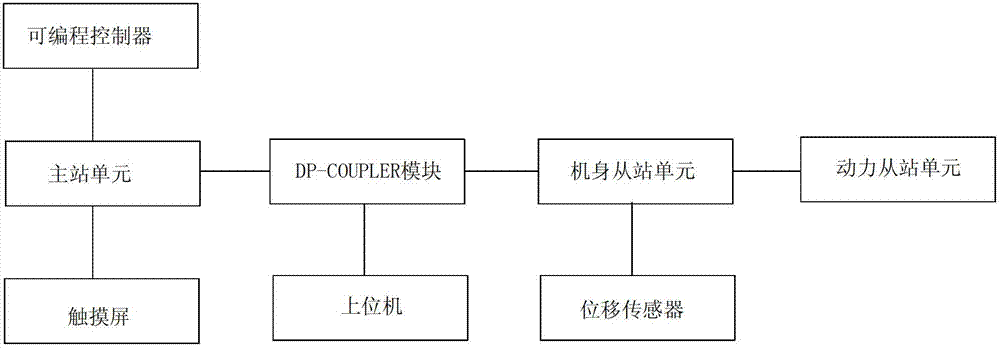

[0016] see figure 1 , an electric control system for an isothermal die forging hydraulic press, including: a host computer, a master station unit, a fuselage slave station unit, a power slave station unit, a displacement sensor, a programmable controller, a touch screen, and a DP-COUPLER module; in this paper In the specific embodiment, what the master station unit selects is Siemens S7-400 series PLC, what the fuselage slave station unit and the power slave station unit select are Siemens ET200S, and the upper computer is a notebook computer or a desktop computer, wherein, the master station unit is the whole The core part of the electronic control system, which is mainly used for coordinated control between various units and modules in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com