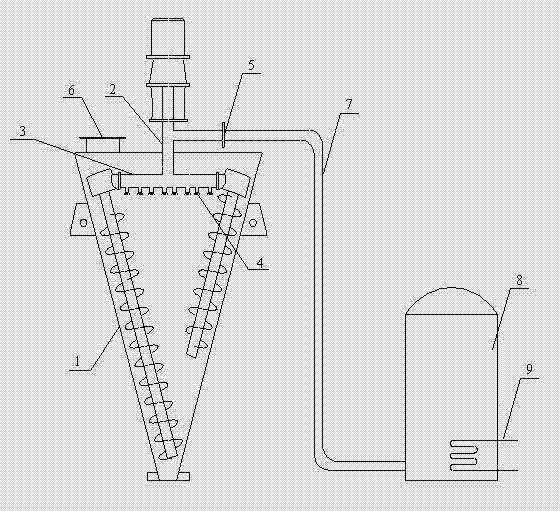

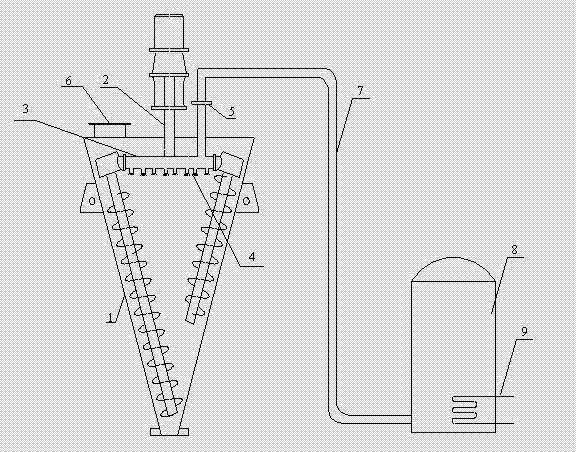

Twin-spiral mixer

A double-screw mixer and rotating shaft technology, applied in mixers, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve the problem of uneven mixing of liquid materials and solid materials, low mixing accuracy and poor mixing efficiency. and other problems, to achieve the effect of easy promotion and use, high mixing accuracy and high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A double-helical mixer, comprising a cylinder 1 and a rotating shaft 2, the cylinder 1 is provided with a horizontal arm 3 connected to the rotating shaft 2, the cylinder 1 is provided with a liquid feed port 5, and the liquid feed port 5 It is connected to the storage tank 8 through the pipeline 7, and the heating coil 9 is arranged in the storage tank 8. The horizontal rotating arm 3 and the rotating shaft 2 are both hollow structures and communicate with each other. The horizontal rotating arm 3 is provided with a spray head 4 , and the liquid feeding port 5 is connected to the rotating shaft 2 .

[0014] When the ambient temperature is low and the viscosity of the liquid is relatively high or the reaction requires a certain temperature, the liquid material in the storage tank 8 can be heated to a certain degree through the heating coil 9 in the storage tank 8, and then the liquid material in the storage tank 8 can be heated from the liquid through the pipeline 9. Th...

Embodiment 2

[0016] A double-helical mixer, comprising a cylinder 1 and a rotating shaft 2, the cylinder 1 is provided with a horizontal arm 3 connected to the rotating shaft 2, the cylinder 1 is provided with a liquid feed port 5, and the liquid feed port 5 It is connected to the storage tank 8 through the pipeline 7, and the heating coil 9 is arranged in the storage tank 8. The horizontal rotating arm 3 is a hollow structure, so that the liquid feed port 5 communicates with the horizontal rotating arm 3 .

[0017] When the ambient temperature is low and the viscosity of the liquid is relatively high or the reaction requires a certain temperature, the liquid material in the storage tank 8 can be heated to a certain degree through the heating coil 9 in the storage tank 8, and then the liquid material in the storage tank 8 can be heated from the liquid through the pipeline 7. The feed port 5 enters the cylinder body 1, and sprays out from the spray head 4 along the horizontal rotating arm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com