Packaging bottle

A technology for packaging bottles and bottle bodies, which is applied in the field of packaging bottles, can solve the problems of flowing to the hand, affecting the service life of liquid, waste, etc., and achieves the effect of avoiding waste and having a simple and practical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

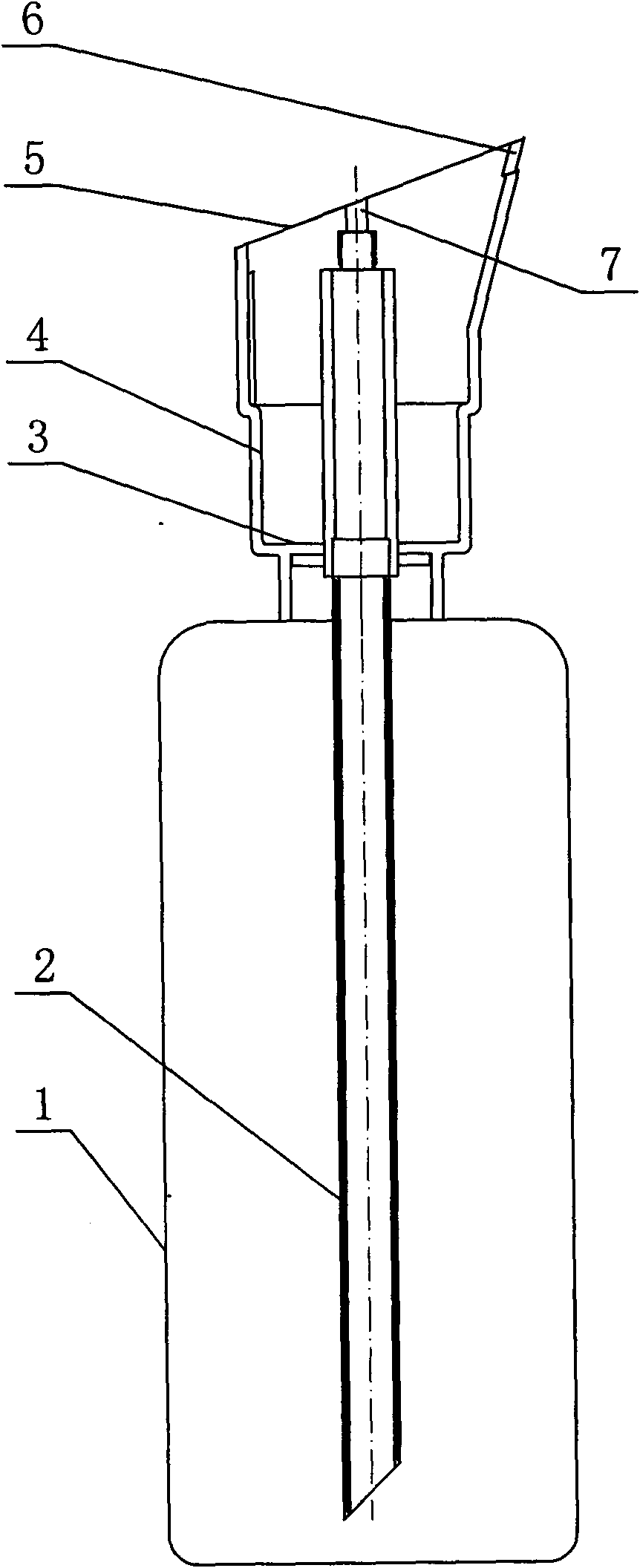

[0010] The present invention includes a flexible bottle body 1 and a measuring cup 4 arranged on the flexible bottle body 1. The measuring cup 4 is provided with a scale, the bottom of the measuring cup 4 is opened and turned outward to form a cross section 3, and a straw is arranged in the bottle body 1. 2 and extend to the upper part of the measuring cup 4, the upper part of the straw 2 is capped, with openings on both sides; the upper part of the measuring cup 4 is provided with a lid 5, a gap 6 is provided between the measuring cup 4 and the lid 5, between the measuring cup 4 and the lid 5 Connected by cap 7.

[0011] The working process of the present invention is: when the present invention is in use, open the lid 5, then open the cap 7, squeeze the soft bottle 1 by hand, the liquid enters the straw 2 and flows upward, and flows out from the openings on both sides of the upper part of the straw 2. When the outflowing liquid reaches the preset scale line, stop squeezing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com