Driving source supply system for electric power tool with attachment

A technology of power tools and supply systems, which is applied in the direction of manufacturing tools, maintenance and safety accessories, and portable motorized devices. It can solve the problems of poor convenience, time-consuming, troublesome, etc., and achieve space saving, reliability, and high dust collection. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0028] [Mode 1]

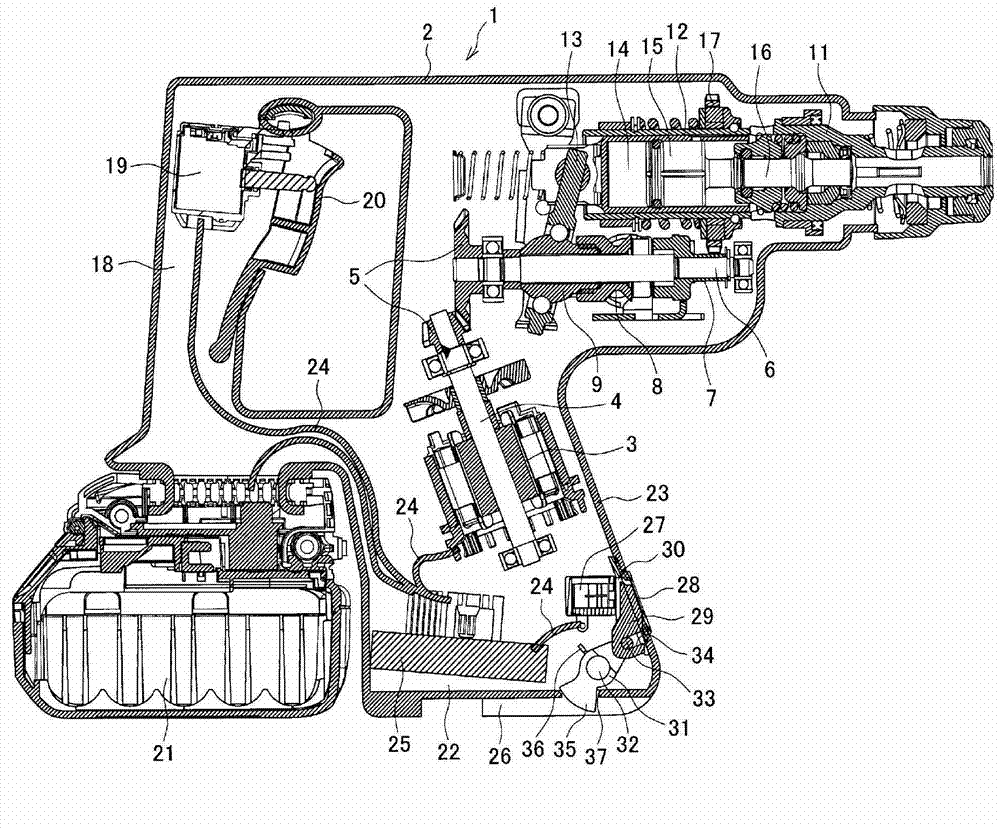

[0029] figure 1 Shown is a power tool with a dust collector installed as an accessory, that is, an electric hammer drill, figure 2 The hammer drill is shown as a single unit. First, the electric hammer drill 1 is assembled on the front side of the casing 2 formed by assembling a pair of left and right split casings (will be figure 1 , figure 2 the right side as the front. ) in the center, the motor 3 is housed in an inclined posture in which the output shaft 4 is inclined rearward, and the intermediate shaft 6 that transmits torque via the bevel gears 5 and 5 above the intermediate shaft 6 is provided with a first gear 7, a clutch 8, and a hub sleeve in this order from the front 9. Above the intermediate shaft 6, a tool holder 11 is pivotally supported in parallel with the intermediate shaft 6. The bit 10 can be inserted into the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com