Hollow spindle with spiral guide grooves

A hollow spindle and guide groove technology is applied in the field of hollow spindles and hollow spindles in twisting devices, which can solve the problems of not considering the law of action, increasing friction, uneven yarn evenness, etc., so as to improve the ability of cohesion and entanglement. The effect of changing the relative position and improving the yarn strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

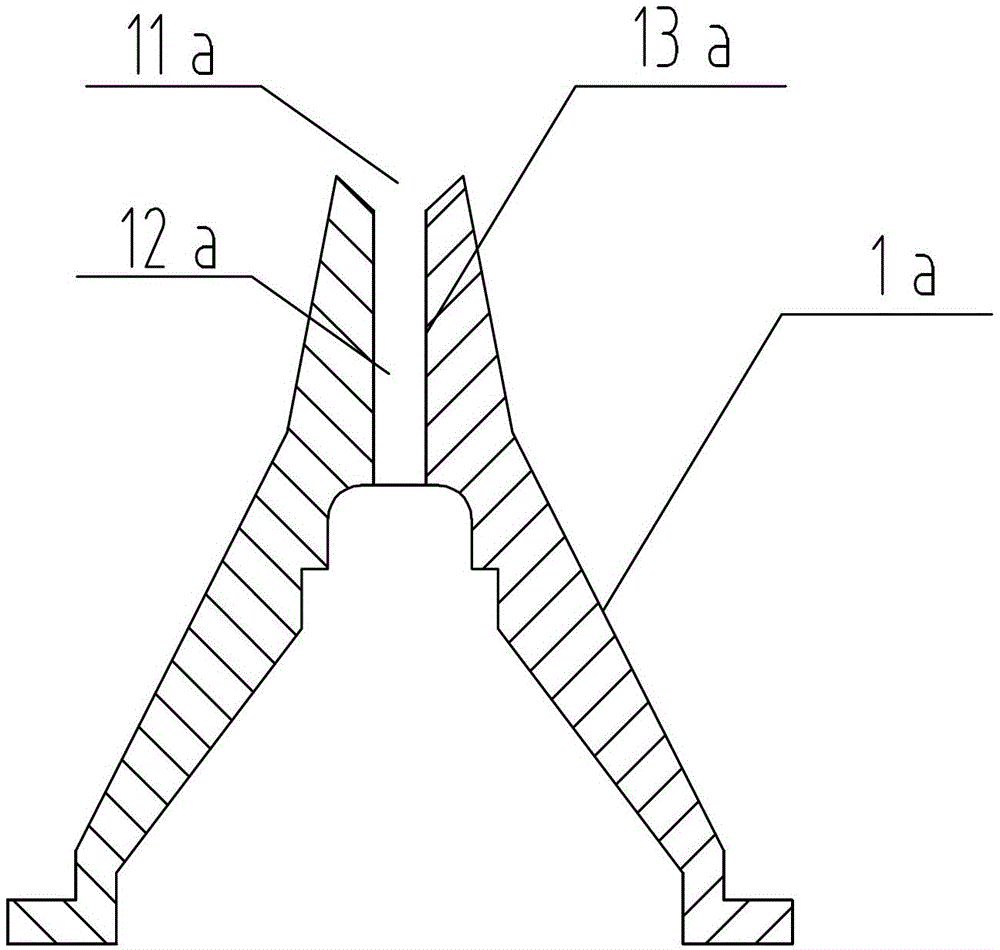

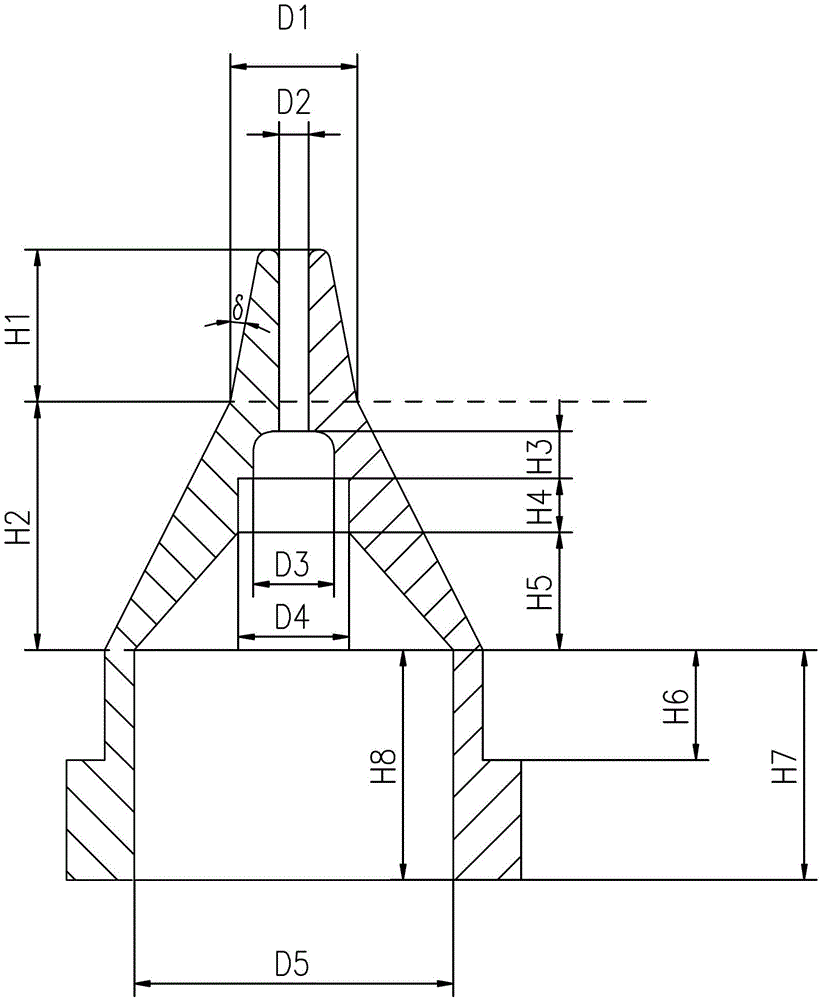

[0030] figure 2 , 3 4. A hollow spindle with a spiral guide groove in the present invention is divided into an upper part 1A, a middle part 1B and a lower part 1C, and the height of the upper part 1A is H 1 5.8mm, the half cone angle of the upper part 1A δ The upper part 1A is provided with a fiber inlet 11 and a yarn guide channel 12, and the outer surfaces of the upper part 1A and the middle part 1B are uniformly provided with 6 guide grooves 13, and the fiber inlet 11 is a smooth structure after chamfering, and the bottom of the upper part 1A diameter D 1 4.8mm, yarn guide channel 12 diameter D 2 is 1.0mm; the middle part 1B is provided with a small inner hole 14, a large inner hole 15 and a cavity 16, and the height of the middle part 1B is H 2 9.2mm, small inner hole 14 diameter D 3 3mm, small inner hole 14 height H 3 2mm, large inner hole 15 diameter D 4 4mm, large inner hole 15 height H 4 2mm, conical cavity 16 height H 5 4.5mm; the lower part 1C is a "convex...

Embodiment 2

[0034] The principle and other settings of this embodiment are the same as those of Embodiment 1, the difference being:

[0035] Upper 1A Height H 1 6.4mm, the half cone angle of the upper part 1A δ is 10°, the number of guide grooves 13 is 6, and the diameter of the bottom end of the upper part 1A is D 1 5.5mm, yarn guide channel 12 diameter D 2 1.2mm; middle part 1B height H 2 10.2mm, small inner hole 14 diameter D 3 3.6mm, small inner hole 14 height H 3 2.4mm, large inner hole 15 diameter D 4 4.8mm, large inner hole 15 height H4 2.6mm, tapered cavity 16 height H 5 4.8mm; hollow spindle outlet 17 inner diameter D 5 10.2mm, the distance H between the bottom of the middle part 1B and the convex surface of the lower part 1C 6 3.6mm, lower part 1C height H 7 7.2mm, hollow spindle outlet height H 8 7.2 mm; the helix angle through which the centerline of the guide groove 13 turns θ is 90°, the groove width L of the guide groove 13 is 0.1~8mm, and the groove depth h of...

Embodiment 3

[0038] The principle and other settings of this embodiment are the same as those of Embodiment 1, the difference being:

[0039] There are 3 guide grooves 13, and the diameter of the bottom end of the upper part 1A is D 1 6.8mm, the diameter D of the yarn guide channel 12 2 1.4mm, small inner hole 14 diameter D 3 4.2mm, large inner hole 15 diameter D 4 5.6mm, hollow spindle outlet 17 inner diameter D 5 12mm, height H of upper part 1A 1 6.8mm, the half cone angle of the upper part 1A δ 12°, height H of middle part 1B 2 11.4mm, small inner hole 14 height H 3 2.2mm, large inner hole 14 height H 4 2.8mm, tapered cavity 16 height H 5 The distance H between the bottom of the middle part 1B and the convex surface of the lower part 1C is 5.2mm 6 4.3mm, lower part 1C height H 7 9 mm, hollow spindle outlet height H 8 8.6 mm; the helix angle that the center line of the guide groove 13 turns θ is 120°, the groove width L of the guide groove 13 is 0.1-10 mm, and the groove de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com