Glass conveying device with adjustable width

A transportation device, glass technology, applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of rising production costs, unfavorable processing and operation of workers, and achieve the effect of convenient processing, convenient operation, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

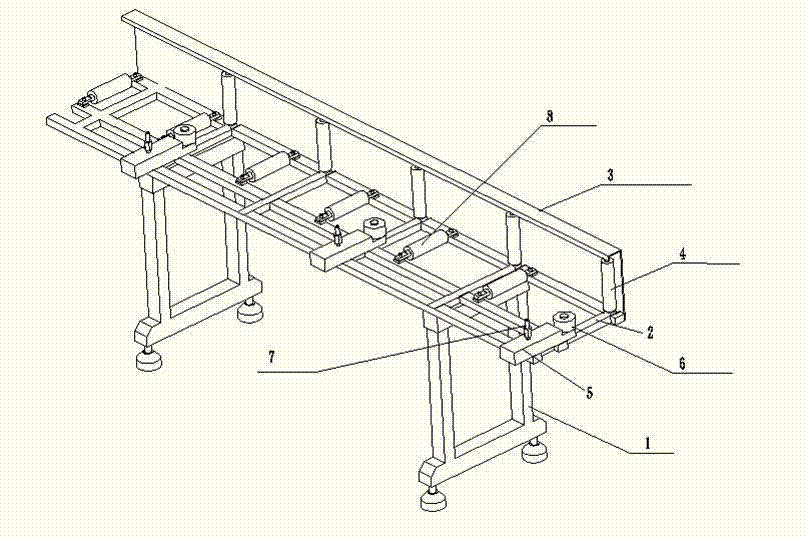

[0007] A specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0008] A glass transportation device with adjustable width, which includes a pillar 1, a bracket 2 fixed on the pillar 1, a lifting roller 8 is arranged in the middle of the bracket 2, and one end of the bracket 2 is fixed with a limited length The roller bracket 3 of the roller, the long limit roller 4 is installed on the roller bracket 3, the opposite side of the fixed side of the bracket 2 and the roller bracket 3 is equipped with a movable roller frame 5, the inner side end of the movable roller frame 5 A short limit roller 6 is provided. Described movable roller frame 5 is regulated left and right position by adjusting screw rod 7.

[0009] Adopting the glass transport device with adjustable width of the present invention can facilitate the operation and processing of workers, and in addition, it can be conveniently adjusted during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com