Reduction of pump nuisance

A pump chamber and pump inlet technology, which is applied in the field of reducing pump pollution, can solve problems such as the quality of beverage preparation equipment or adverse effects of operation, and achieve the effects of increasing the risk of fluid leakage, increasing costs, and simplifying assembly steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

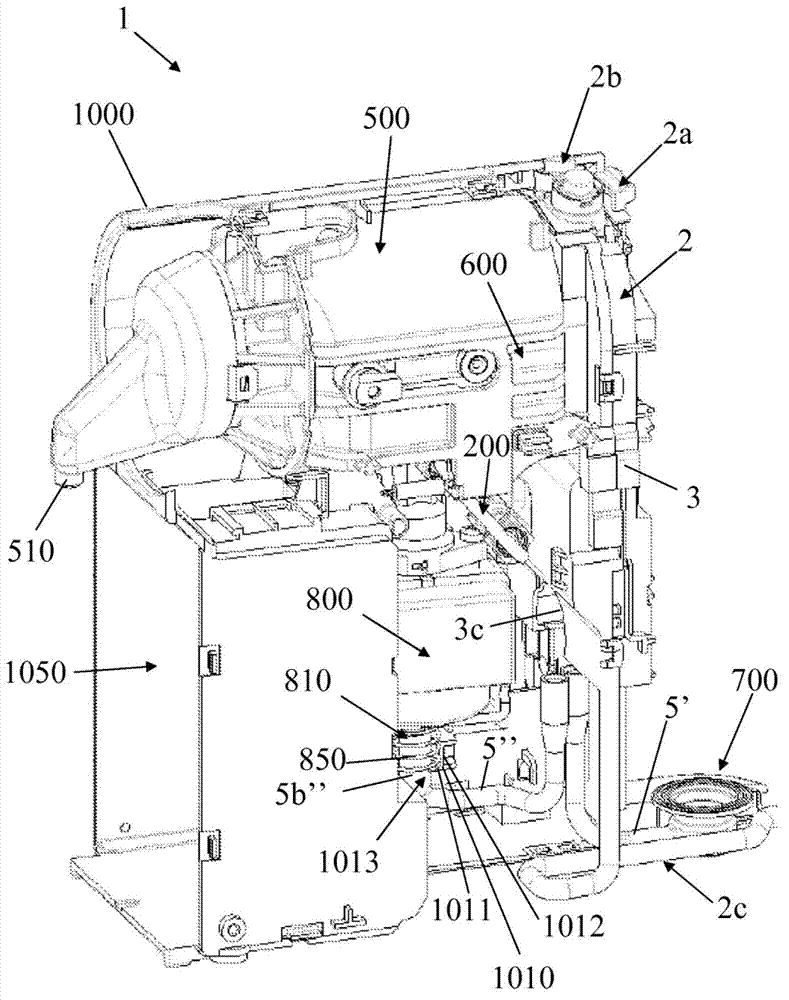

[0051] figure 1 Different parts of the beverage preparation machine 1 are shown. Generally, such beverage preparation machines are suitable for preparing coffee, tea and / or other hot drinks including soups and similar food preparations. The pressure of the liquid circulated to the brewing chamber may for example be up to about 10-20 bar. Various components of a beverage preparation machine 1 and components thereof are generally disclosed in WO 2009 / 130099, the content of which application is hereby incorporated by reference.

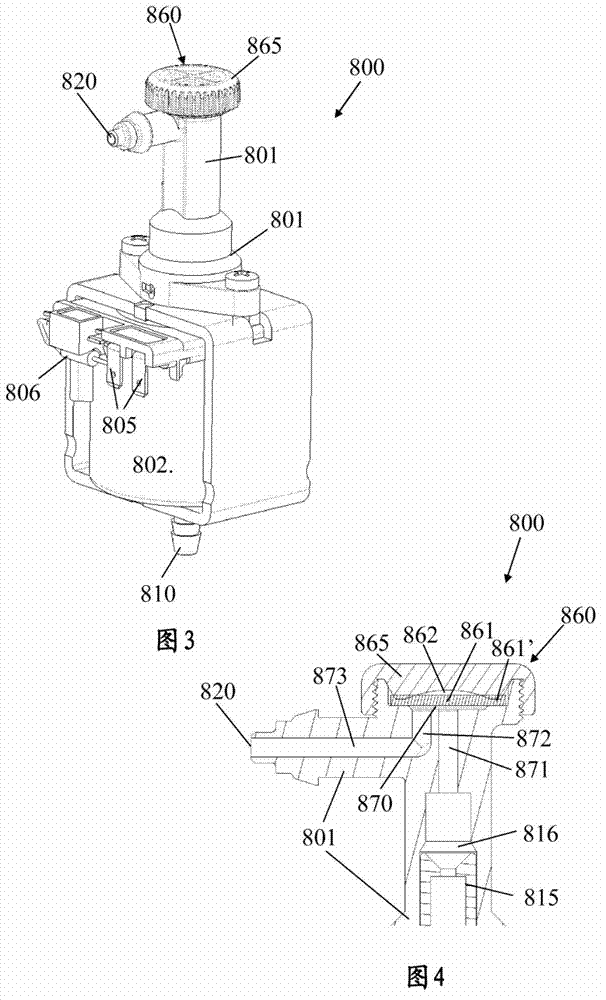

[0052] figure 1 In general a general view of the internal structure which may be present in a beverage preparation machine 1 according to the invention is provided. figure 2 A particular embodiment of a pump 800 installed in a beverage preparation machine 1 is shown in more detail. image 3 and 4 One embodiment of a pump 800 according to the invention is shown in more detail.

[0053] In a perspective view of a part of the beverage preparation mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com