Hasp structure

A technology of buckle parts and movable parts, which is applied in the direction of connecting components, hooks, mechanical equipment, etc., and can solve problems such as disconnection of lamps, potential safety hazards, unstable locking of lamp housings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

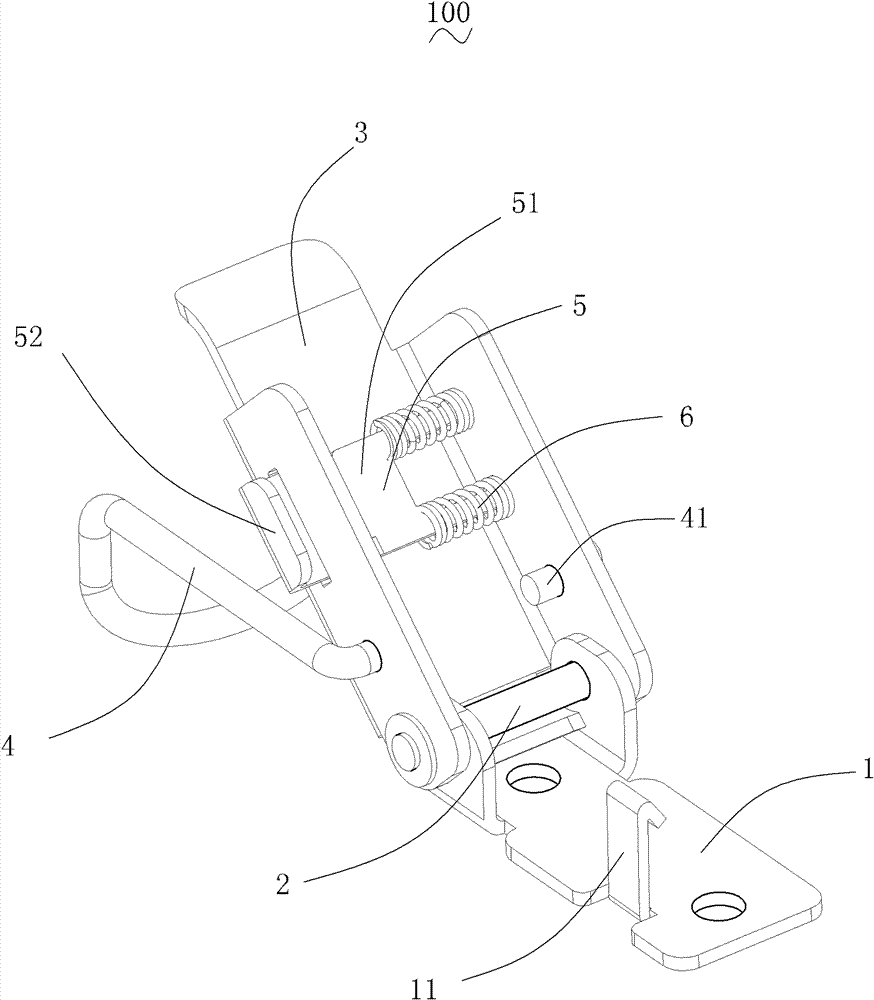

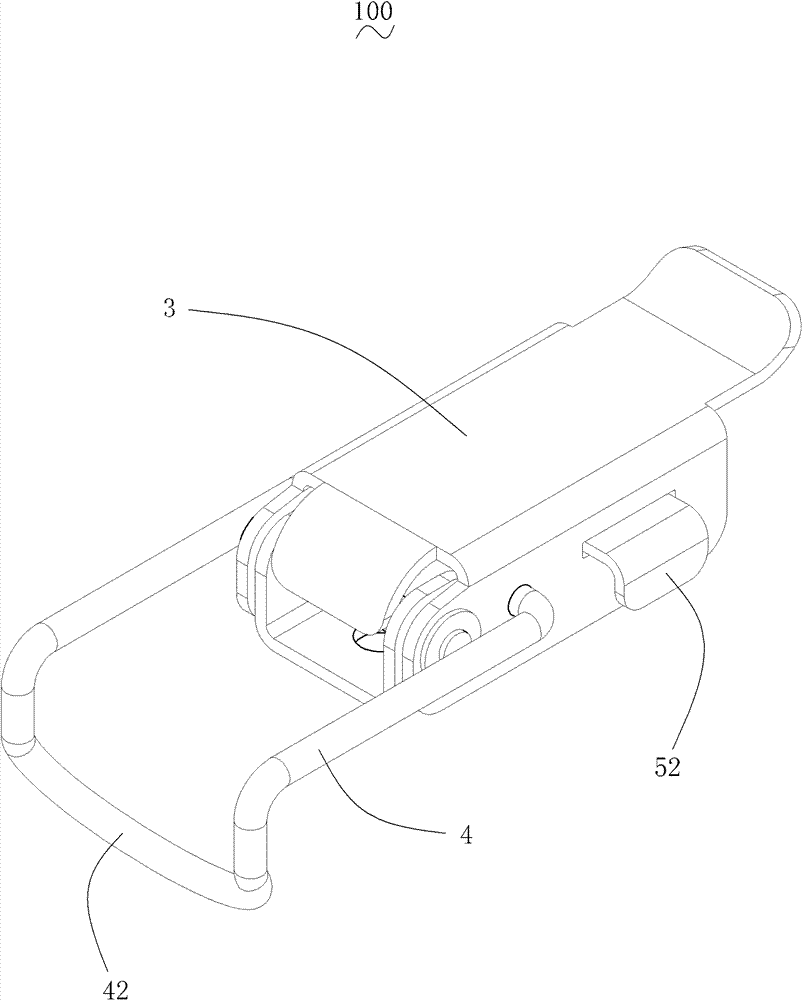

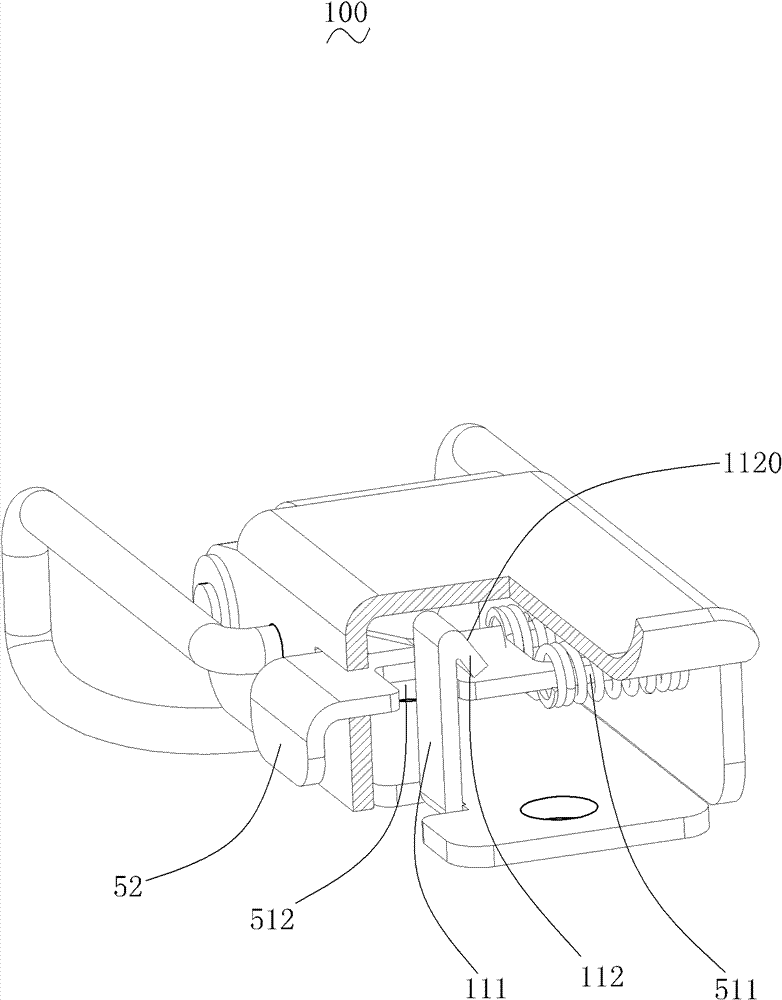

[0018] Please refer to Figure 1 to Figure 5 , the buckle structure 100 of this embodiment is used to lock the lamp housing (not shown). The buckle structure 100 includes a base 1 , a pin assembly 2 passing through the base 1 , a movable part 3 connected to the base 1 through the pin assembly 2 , and a hasp 4 assembled on the movable part 3 . The buckle structure 100 also includes a locking part 5, an elastic element 6 connecting the locking part 5 and the movable part 3, and a buckle part 11 extending from the base 1. The locking part 5, the elastic element 6 and the buckle part 11 are composed of Self-locking structure.

[0019] special reference Figure 4 The base body 1 is provided with a base plate 10 and a pivot portion 12 extending from one end of the base plate 10 at an angle to the base plate 10 . The base plate 10 is locked to the lamp holder (not shown), and a through hole is formed on the pivot joint 12 , through which the pin shaft assembly 2 passes to pivotall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com