Linear compressor with damping structure

A linear compressor, linear motor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as difficulty in improving compressor efficiency, and achieve reduced vibration, good stability, and frequency range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

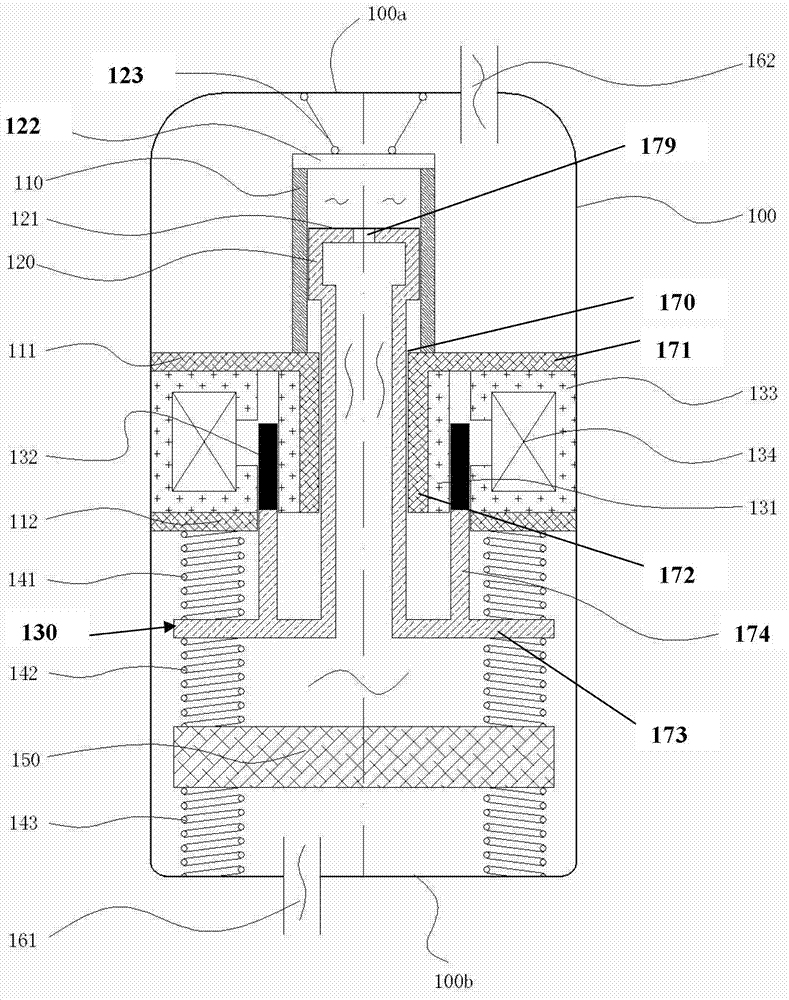

[0015] Such as figure 1 As shown, the linear compressor with a shock absorbing structure provided in this embodiment mainly includes an airtight container 100 and an upper fixed frame 111, a lower fixed frame 112, a linear motor, a cylinder 110, a piston 120, an air suction Valve plate 121, exhaust valve 122, multiple springs 123, connecting device 130, upper spring group 141, middle spring group 142, lower spring group 143 and mass element 150; An air inlet 161 is provided, and an air outlet 162 is provided on the top surface 100a; the upper fixing frame 111 is composed of an annular horizontal surface 171 with a central hole 170 and a cylindrical side wall 172 formed by vertically extending downward from the edge of the central hole 170 It is integrally formed, and the outer circumference of the horizontal plane 171 is connected to the inner circumference of the airtight container 100; the lower fixing frame 112 is annular, and its outer circumference is fixed on the inner c...

Embodiment 2

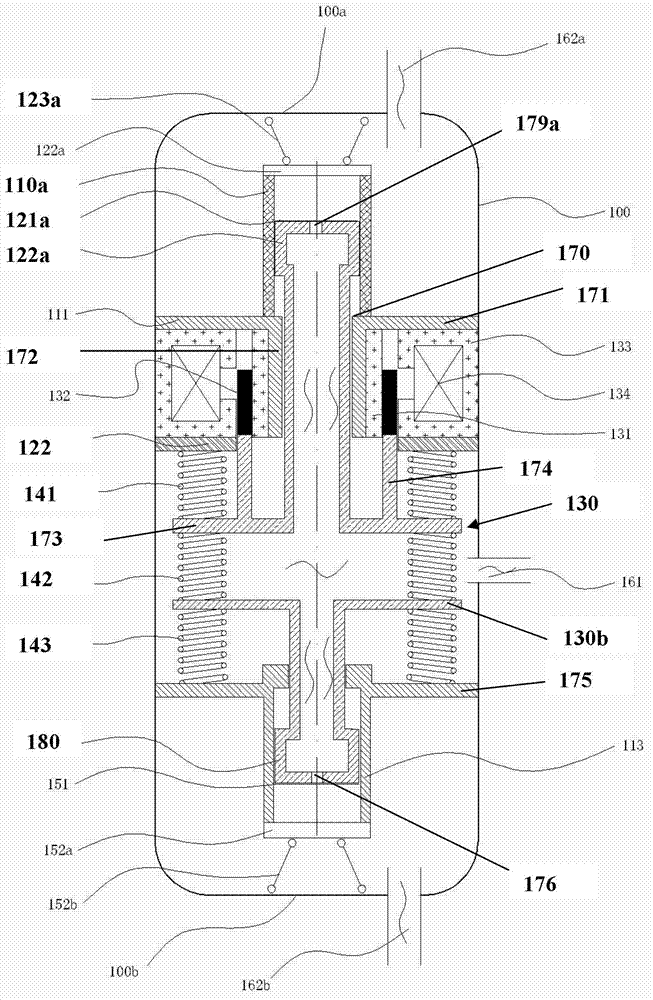

[0020] Such as figure 2As shown, the linear compressor with a shock absorbing structure provided in this embodiment mainly includes an airtight container 100 and an upper fixed frame 111, a lower fixed frame 112, a linear motor, an upper cylinder 110a, an upper piston 120a, Upper suction valve plate 121a, upper exhaust valve 122a, multiple upper springs 123a, connecting device 130, upper spring group 141, middle spring group 142, lower spring group 143, lower cylinder 113, lower piston 180, lower suction valve Sheet 151, lower exhaust valve 152a and a plurality of lower springs 152b; wherein airtight container 100 is cylindrical, and its side is provided with air inlet 161, and top surface 100a and bottom surface 100b are respectively provided with an upper air outlet 162a and a The lower air outlet 162b; the upper fixed frame 111 is composed of an annular horizontal surface 171 with a central hole 170 and a cylindrical side wall 172 formed by vertically extending downward fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com