End part sealing method of sintering machine

An end sealing and sintering machine technology, applied in the field of sintering machine sealing, can solve the problems of sealing surface wear of the sealing device, large air leakage at the end of the sintering machine, air leakage at the end of the sintering machine, etc., so as to reduce the air volume and improve the fit. effect, the effect of improving the service life and the reliability of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

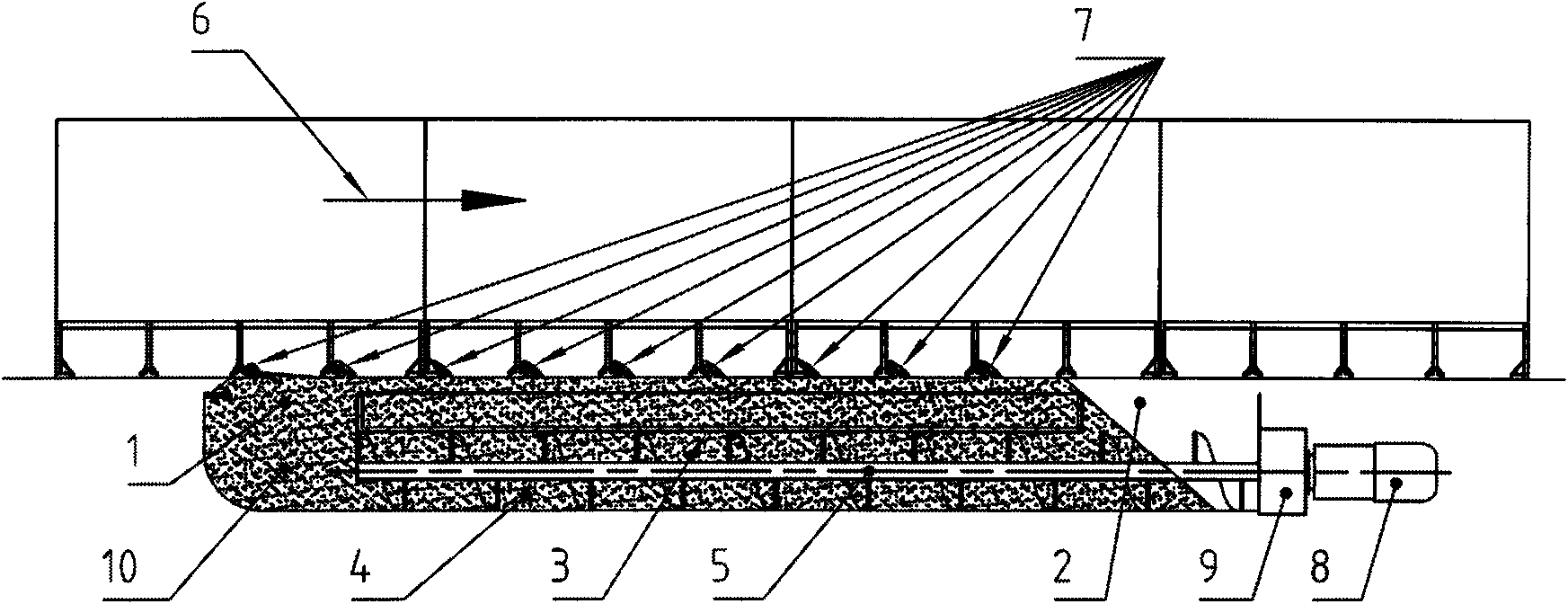

[0021] Example 1, such as figure 1 shown.

[0022] exist figure 1 Among them, 1 is the sand outlet provided at the front end of the end sealing device, the sand outlet 1 can be independent, or it can be implied in the outlet of the sand conveying device, such as a screw conveyor, in other words In other words, the sand outlet 1 can be integrated with the outlet of the sand conveying device, such as a screw conveyor. 2 is the falling sand tank provided at the rear end of the end sealing device. 3 is a sand table arranged between the sand outlet and the sand falling tank. 4 is a sand returning channel arranged between the sand outlet and the sand falling tank. 5 is the conveying device of sand, specifically, what it has adopted is a screw conveyor. It should be noted that the sand return passage 4 and the conveying device 5 of sand (specifically, it adopts a screw conveyor) are combined into one. Arrow 6 represents the forward direction of the sintering trolley. 7 represe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com