Industrial truck with limit switch assembly

A technology of transport vehicles and limit switches, which is applied in the direction of lifting devices, lifting equipment safety devices, etc., and can solve the problems of lowering the function of forks and additional functions of column translation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

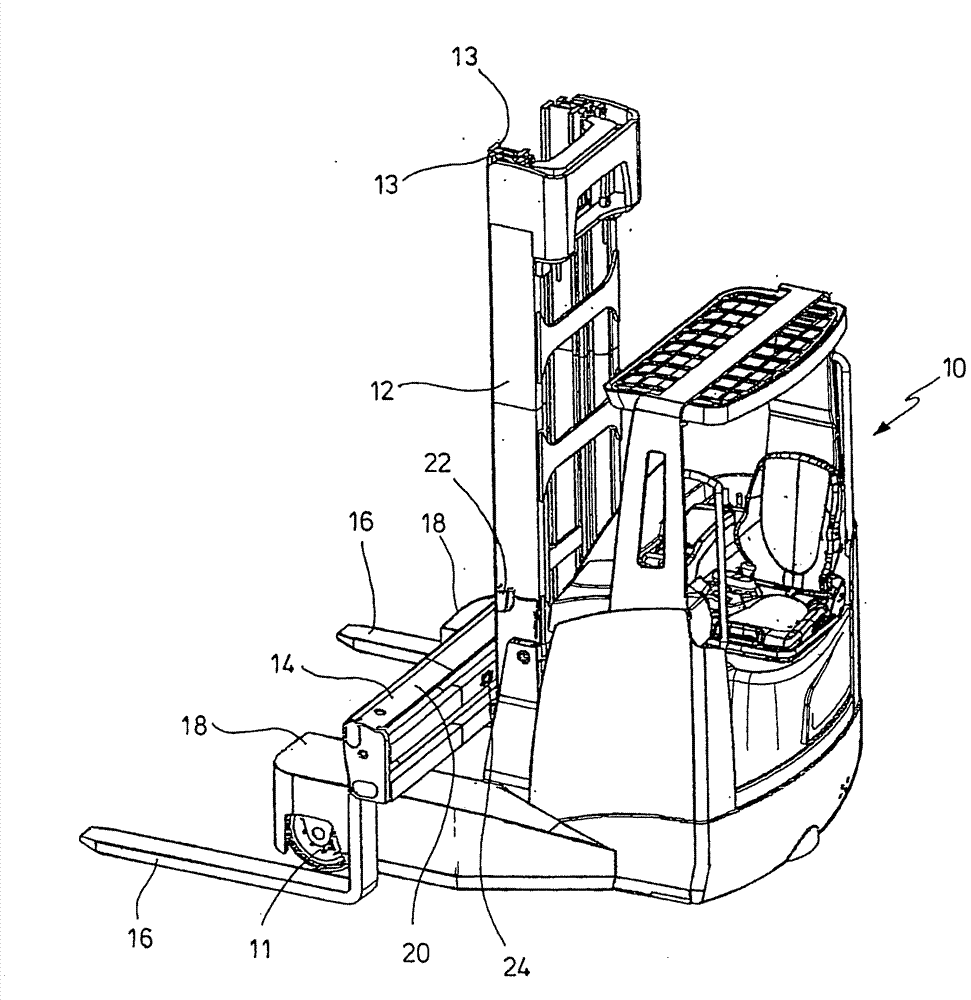

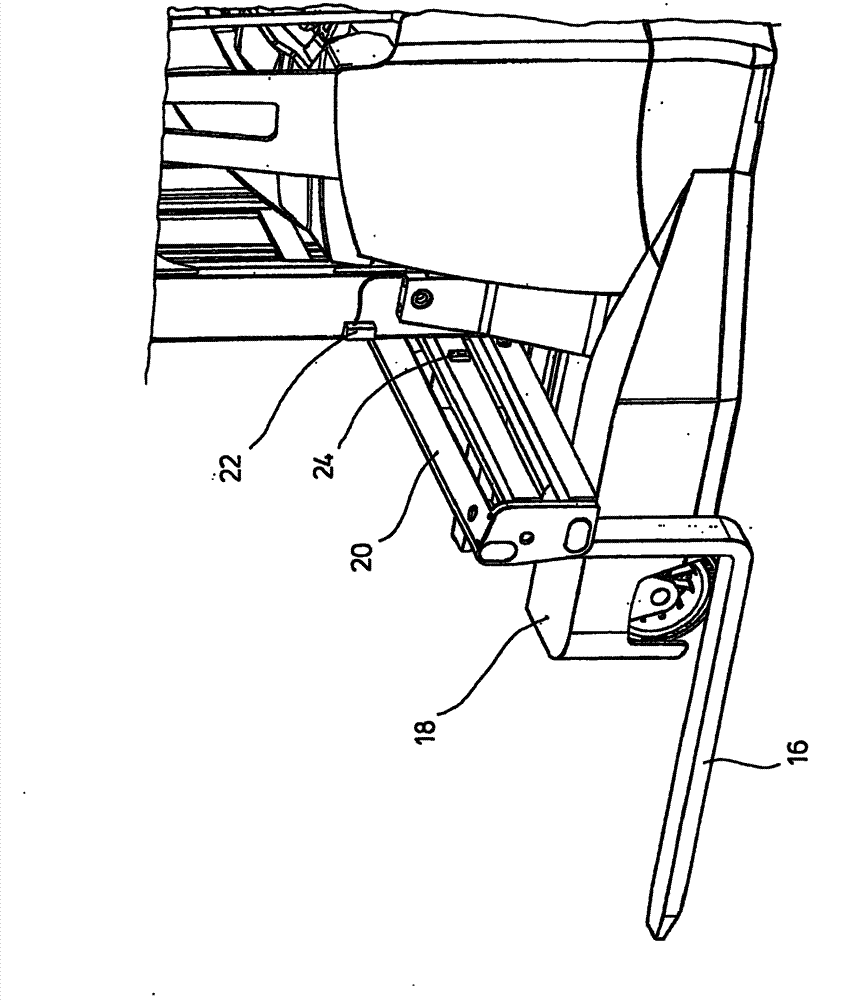

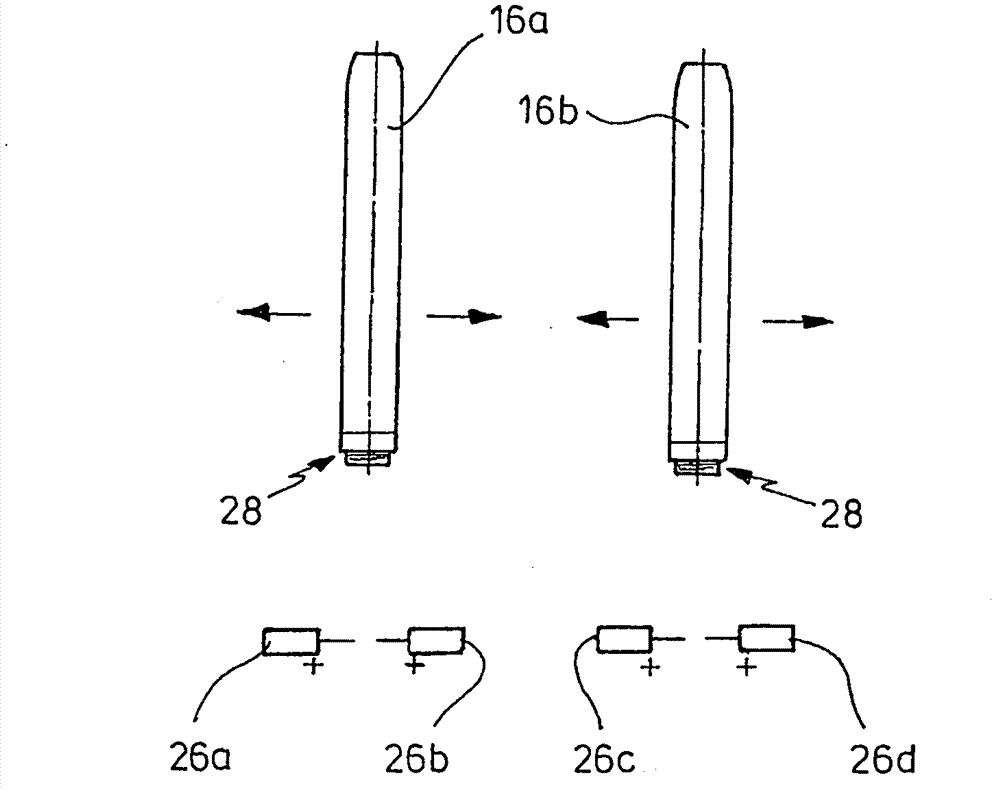

[0021] figure 1 The reach truck 10 is shown in a perspective view, the right front wheel 11 being visible. The reach truck 10 has a lifting frame 12 with two extendable column sections 13 (not shown). Furthermore, a carrying device 14 is mounted on the lifting frame 12 , said carrying device being adjustable in its height on the lifting frame 12 . Described carrying device 14 has two goods fork tines 16 that are arranged parallel to each other, and these two goods fork tines are in figure 1 The middle falls on the outside of the wheel support arm 18 . The carrier device 14 is designed as a tine adjustment device 20 which allows individual lateral adjustment of the tines 16 so that they can be positioned on the inside of the wheel support arm 18 or the wheel support arm, for example. The outer side of the 18 is lowered. The adjustment of the fork tines into their lateral position makes it possible to accommodate long objects during transport and support them by the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com