System and method combining virtual situation and used for managing production line

A production line management and virtual situation technology, applied in the field of production line management system, can solve problems such as adjustment of performance evaluation methods, decline in the recognition of production line managers' performance evaluation methods, and impact on production efficiency, so as to improve initiative and enthusiasm, and reduce inquiries. time, the effect of reducing the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

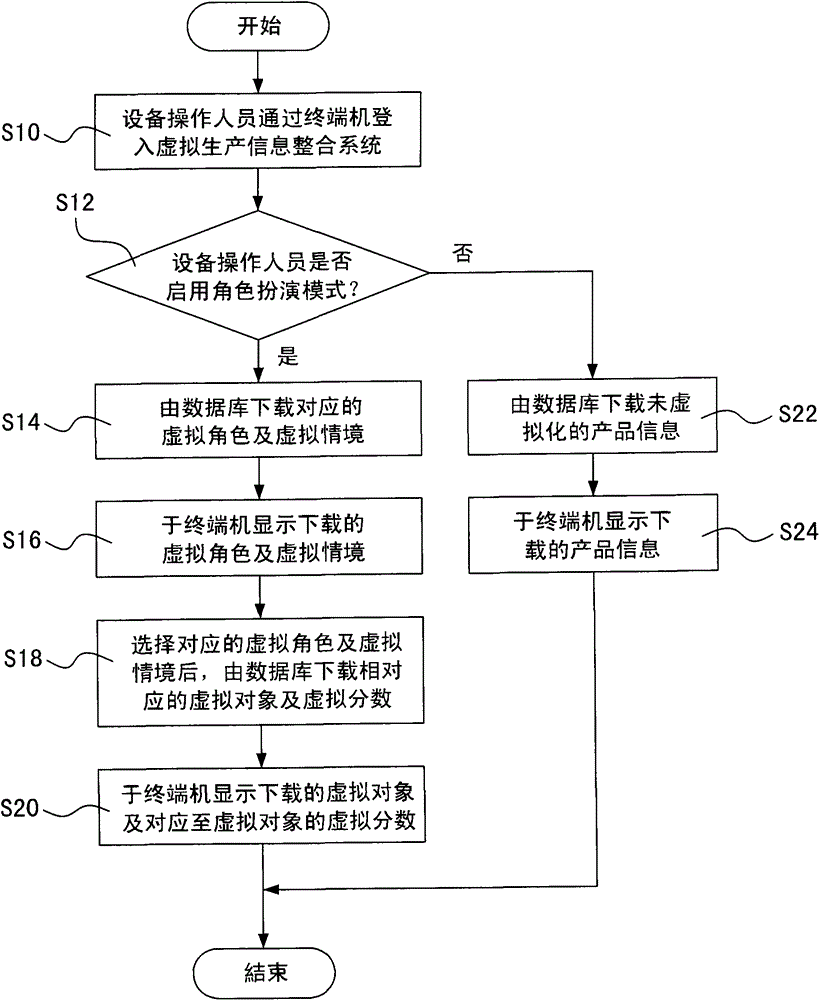

[0076] With regard to a preferred embodiment of the present invention, with the accompanying drawings, the detailed description is as follows.

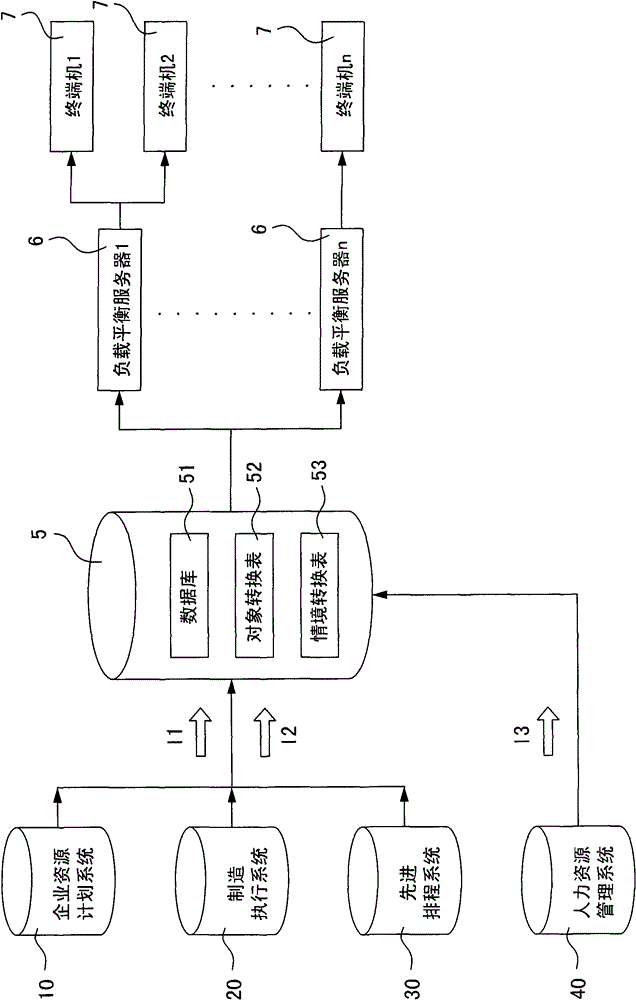

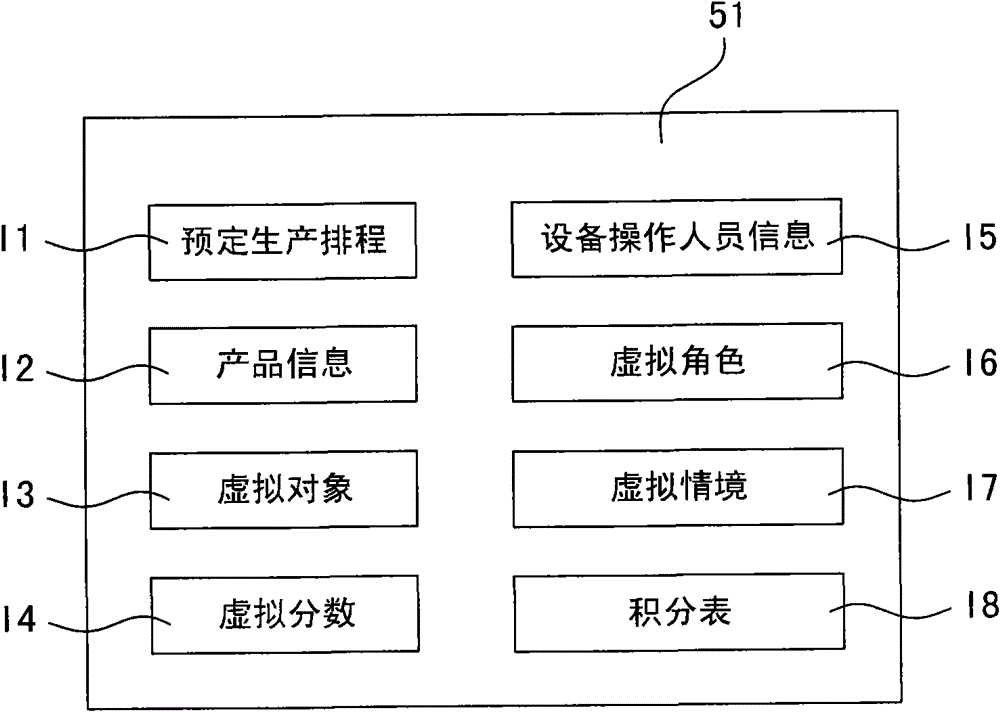

[0077] First see figure 1 , Is a system architecture diagram of a preferred embodiment of the present invention. The present invention is mainly composed of an enterprise resource planning (ERP) system 10, a manufacturing execution system (Manufacturing Execution System, MES) 20, an advanced scheduling (Advanced Planning and Scheduling, APS) system 30, and a human resources A management system (Human Resource Managing System, HRMS) 40, multiple load balancing servers 6 and multiple terminals 7 constitute a production line management system. And the production line management system also includes a virtual production information integration system 5 (hereinafter referred to as the integration system 5 for short).

[0078] The integrated system 5 connects the ERP 10, the MES 20, the APS 30, and the HRMS 40 to receive text data streams (such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com