Whole lifting-type underground garage

An underground garage and overall lifting technology, which is applied in the field of parking devices and layered underground garages, can solve the problems of long time for picking and placing cars, large amount of basic engineering, complex mechanism, etc., achieve short car access time and improve utilization high efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

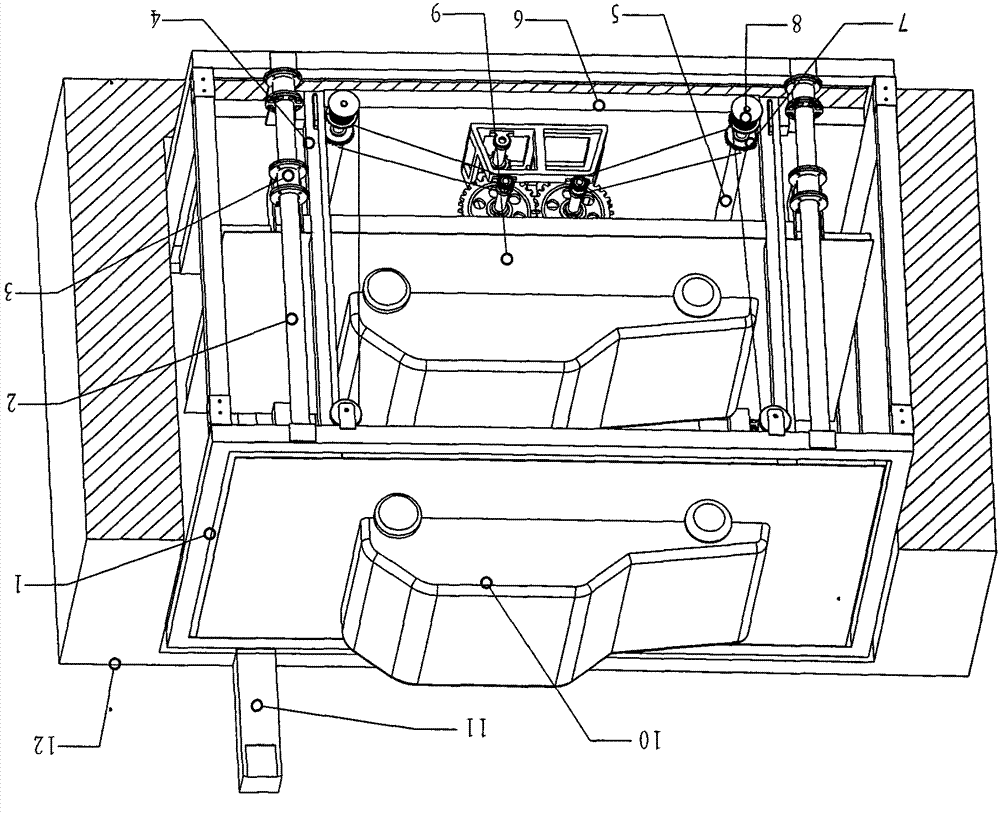

[0018] Make waterproof wall (12) on the basis of excavation, and cast concrete at the bottom at the same time to make it waterproof; align and prepare the flat installation surface; assemble the large garage frame (1) on the flat installation surface, and find Just, four fixed pulleys (13) are installed at the relevant position of the top.

[0019] Insert the linear bearing (3) into the upper and lower track shafts (2), install it on the garage frame (1), and find the precise position of the upper and lower track shafts (2); Load the model steel (4) and the vehicle-carrying plate (9) in groups, and then transport them to the installation position of the garage frame (1); assemble the linear bearing (3) on the power plate (6) and the vehicle-carrying plate at the lowest position The corresponding exact position of the plate (9).

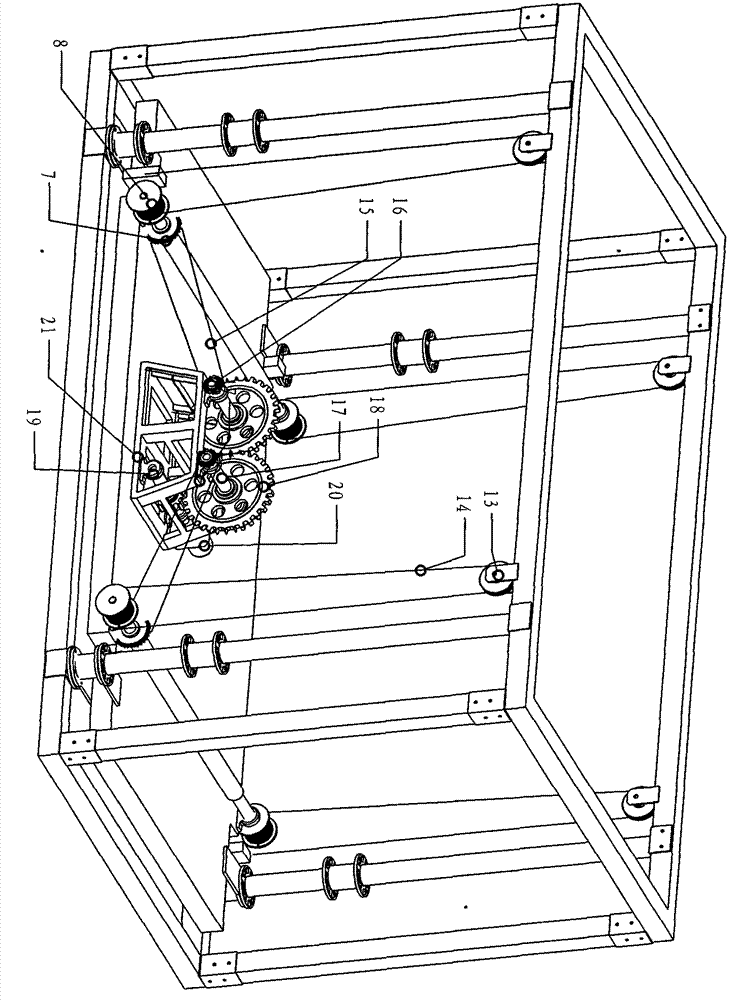

[0020] Install relevant components on the power frame (21), including: gear shaft (17), gear (18), drive sprocket (16), power input shaft (19), vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com