Synchronous regulating device with inlet guide blades for high-speed centrifugal fan

The technology of inlet guide vane and synchronous adjustment is applied in the field of synchronous adjustment device and the mechanical device for synchronous adjustment of the angle of the inlet guide vane, which can solve the problems of high manufacturing cost and complicated structure, and achieves low manufacturing cost, simple structure, and ensures synchronous adjustment. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in conjunction with the accompanying drawings:

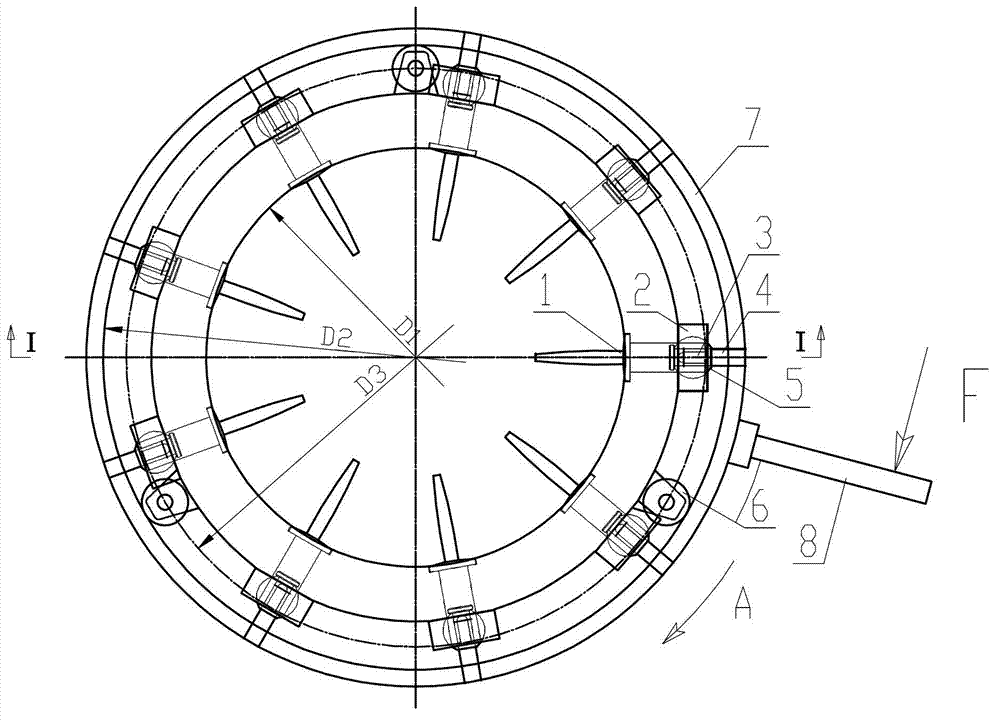

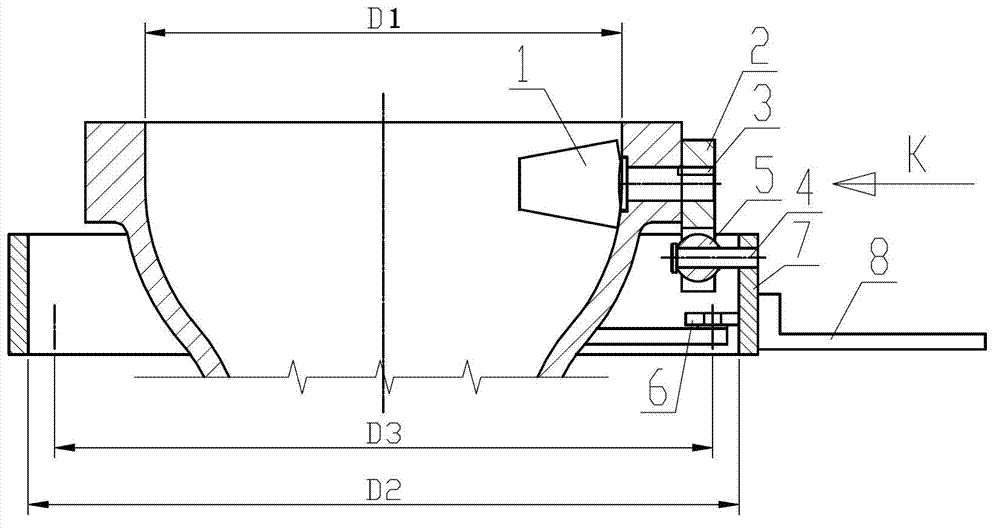

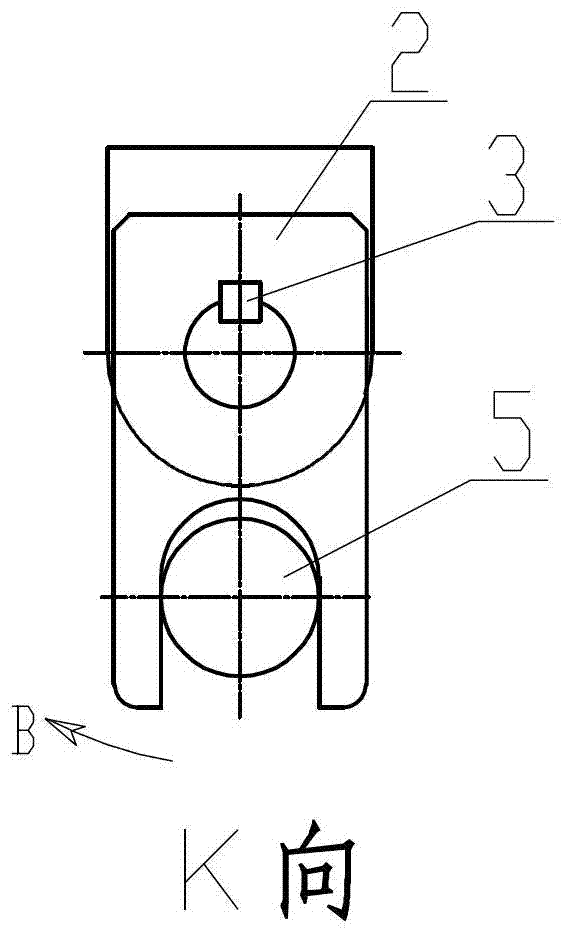

[0014] Such as figure 1 , figure 2 As shown: the present invention includes guide vane 1, rotating arm 2, key 3, pin 4, ball 5, roller 6, rotating ring 7, driving arm 8 and so on.

[0015] The synchronous adjustment device for the inlet guide vanes of the high-speed centrifugal fan includes 9-21 guide vanes 1, rotating arm 2, key 3, pin 4, sphere 5, roller 6, rotating ring 7, driving arm 8; 9-21 guide vanes Each guide vane journal in 1 is respectively installed in the evenly distributed shaft holes on the circumference of the upper part of the inner volute with a diameter of D1 to form a first rotating pair; one end of each rotating arm 2 is connected to each guide vane through a key 3 The journal 1 is fixedly connected, and the other end of each arm 2 has a U-shaped groove connected to each ball 5 to form a spherical motion pair; the number of the ball 5 is equal to the number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com