Semiautomatic reforming tool of casting piece

A semi-automatic, casting technology, applied in the field of mechanical processing, can solve the problems of inability to accurately control the amount of shaping, high labor intensity of workers, and low production efficiency, so as to accurately control the quality of product shaping, reduce labor intensity of workers, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

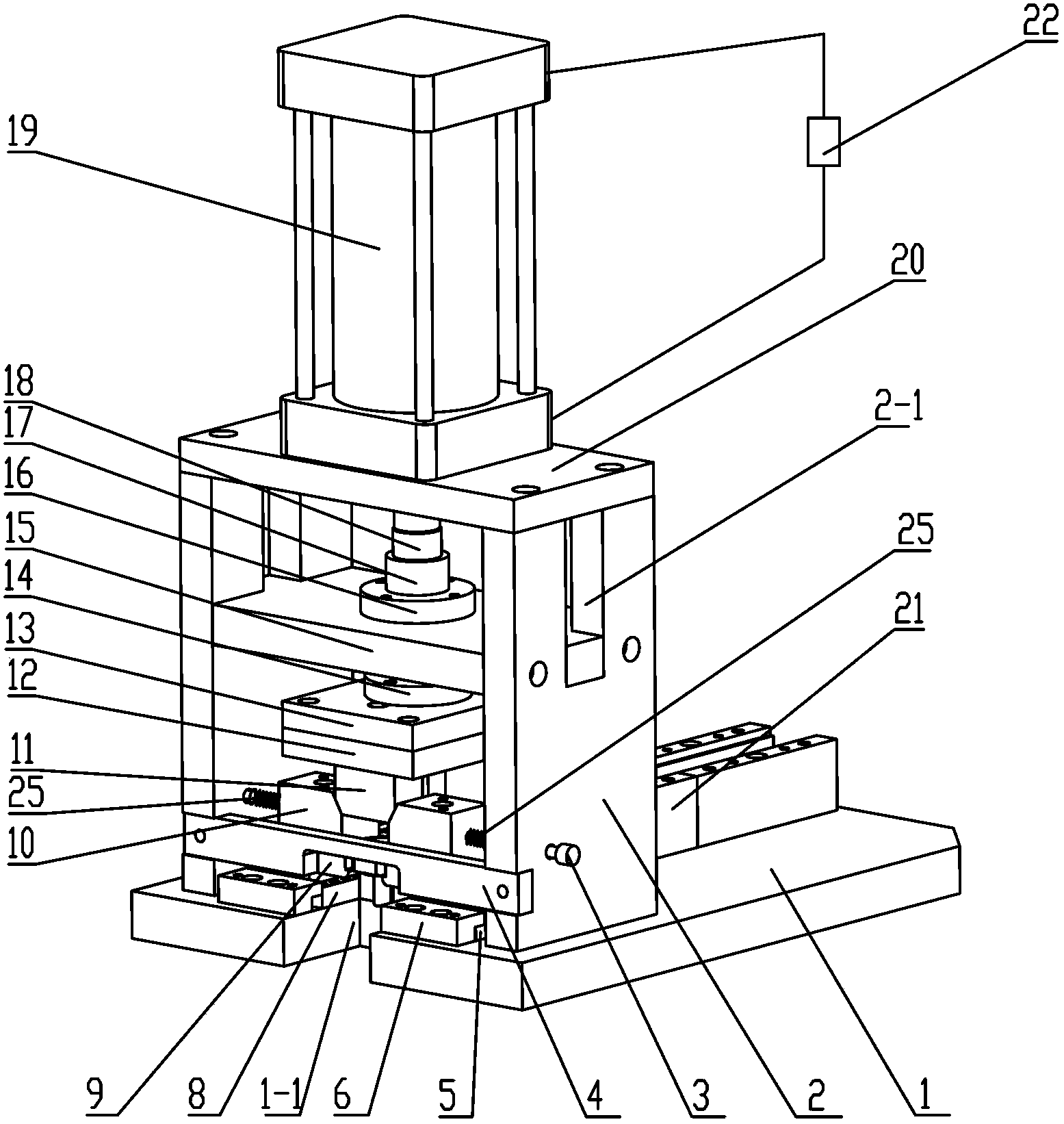

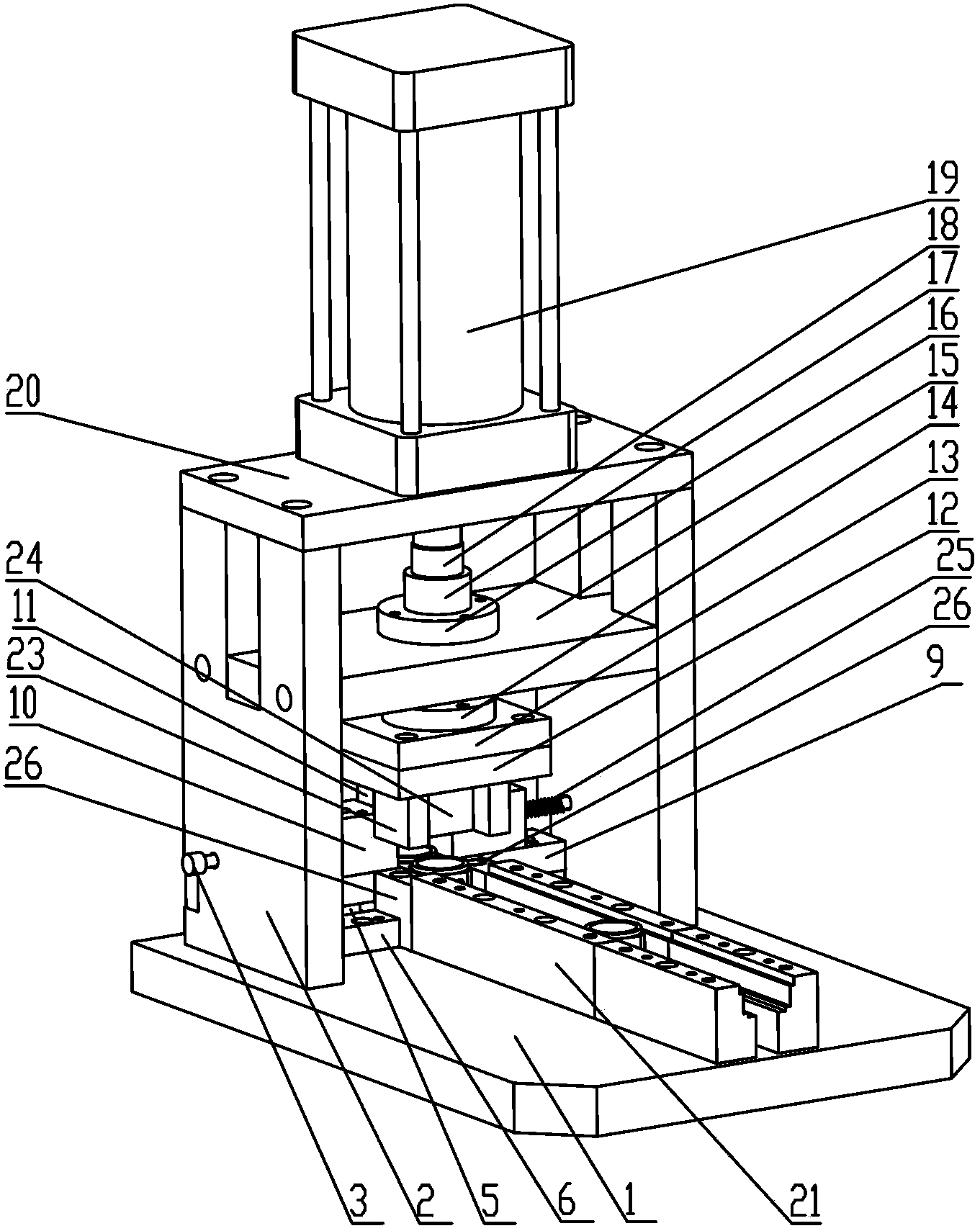

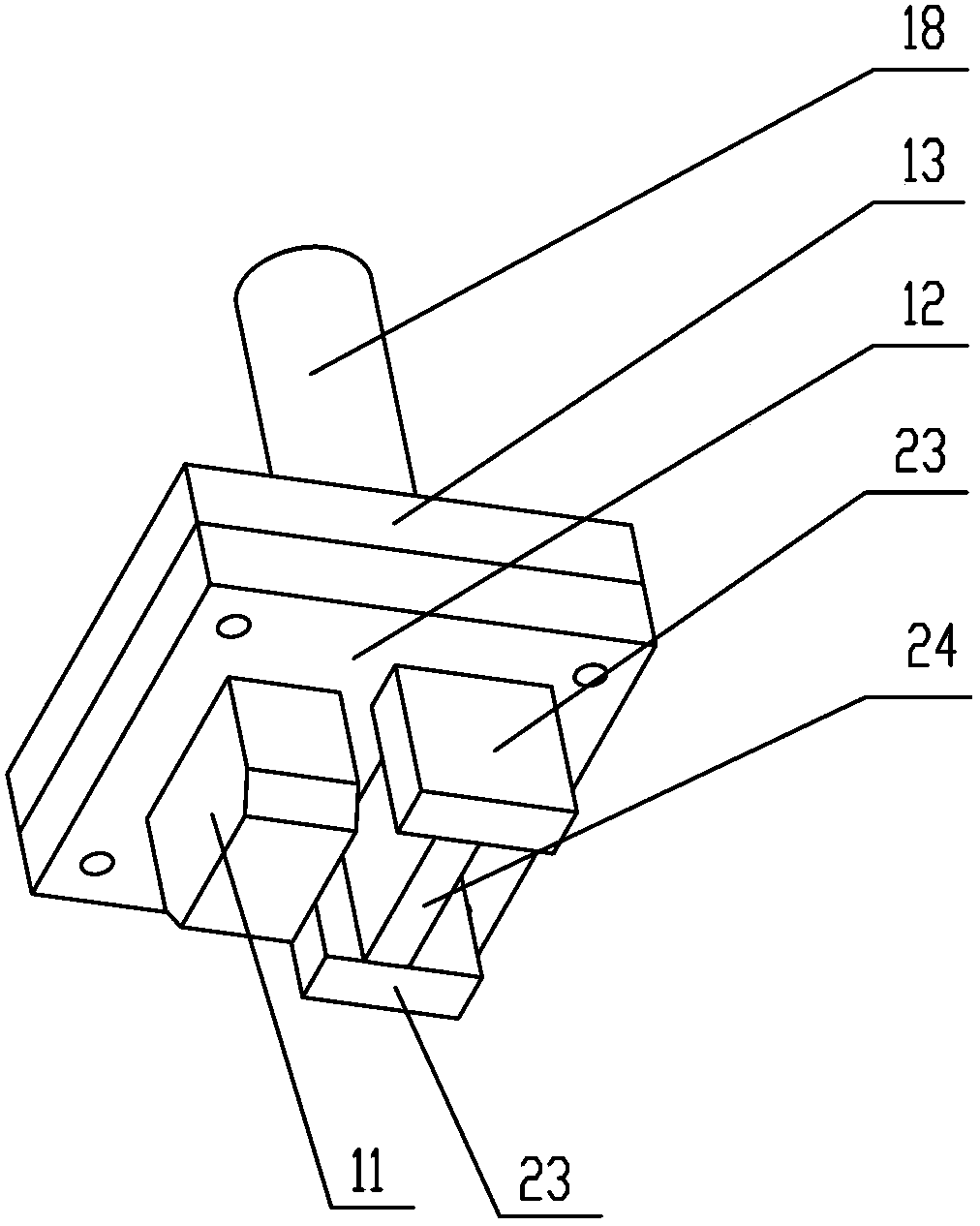

[0016] The present invention mainly comprises base plate 1, supporting plate 2, slide rail 6, supporting plate 9, corner block 10, punch, guide sleeve fixing plate 15, gas-liquid booster cylinder 19 and cylinder fixing plate 20.

[0017] The bottom plate 1 is provided with a discharge port 1-1, and a slide rail 6 is respectively arranged on both sides of the discharge port 1-1. The slide rail 6 is connected to the supporting plate 9 through the slider 5, and the corner block is fixed on the supporting plate 9. 10. The inner surface of the corner block 10 is a slope. The inner side of the slide rail 6 is connected with a limit block 8, and the limit block 8 prevents the slide block from falling off from the slide rail 6.

[0018] The left and right sides of the bottom plate 1 are respectively connected with a support plate 2 , and the upper ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com