Device and system for monitoring liquefied petroleum gas steel cylinder

A technology of liquefied petroleum gas and steel cylinders, which is applied in the container discharge method, gas/liquid distribution and storage, container filling method, etc., can solve the problems of poor reliability of the detection process, save manpower and material resources, and avoid manual inspection work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

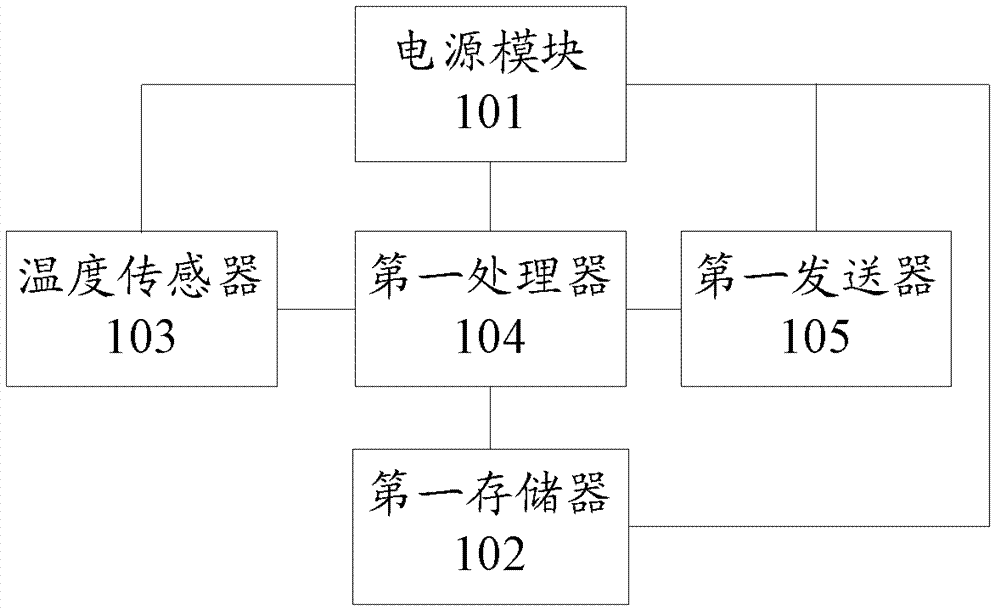

[0043] figure 1 It is a schematic structural diagram of a device for monitoring a liquefied petroleum gas cylinder provided in the first embodiment of the present invention. figure 1 The devices shown include:

[0044] The power supply module 101 is used to supply power to the device;

[0045] The first memory 102 is used to store identification information of the liquefied petroleum gas cylinder;

[0046] The temperature sensor 103 is used to monitor the temperature of the surface of the liquefied petroleum gas cylinder and generate a digital signal of temperature information;

[0047] The first processor 104 is connected to the first memory 102 and the temperature sensor 103, and is configured to generate a first monitoring signal including temperature information and identification information of the liquefied petroleum gas cylinder;

[0048] The first transmitter 105 is connected to the first processor 104 and is configured to send the first monitoring signal.

[0049] The device pro...

Embodiment 2

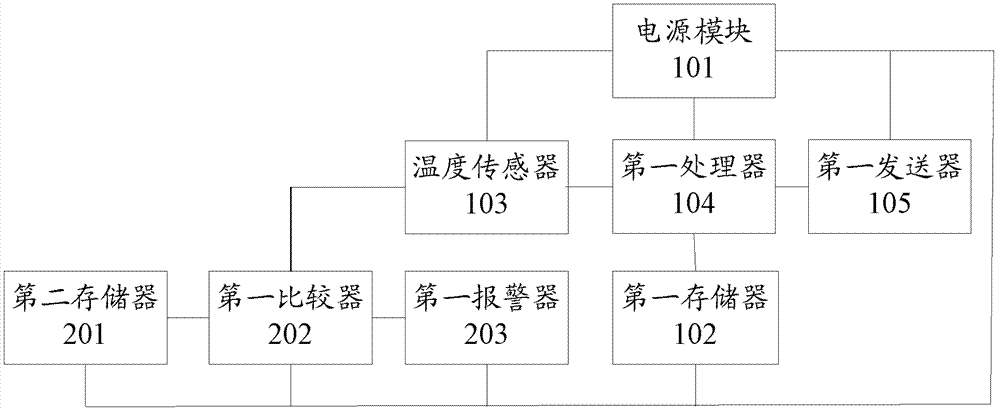

[0051] figure 2 for figure 1 Another schematic diagram of the device shown. versus figure 1 The difference in the device shown is that figure 2 The device shown also includes:

[0052] The second storage 201 is configured to store the threshold value of the surface temperature of the liquefied petroleum gas cylinder;

[0053] The first comparator 202 is connected to the second memory 201 and the temperature sensor 103, and is used to compare the temperature information obtained by the temperature sensor with the temperature threshold to obtain a comparison result;

[0054] The first alarm 203 is connected to the first comparator 202 and is configured to issue an alarm when the comparison result is that the temperature obtained by the temperature sensor is greater than the temperature threshold.

[0055] The difference from the first embodiment is that the device provided in the second embodiment compares the current temperature with the temperature threshold, and can obtain informat...

Embodiment 3

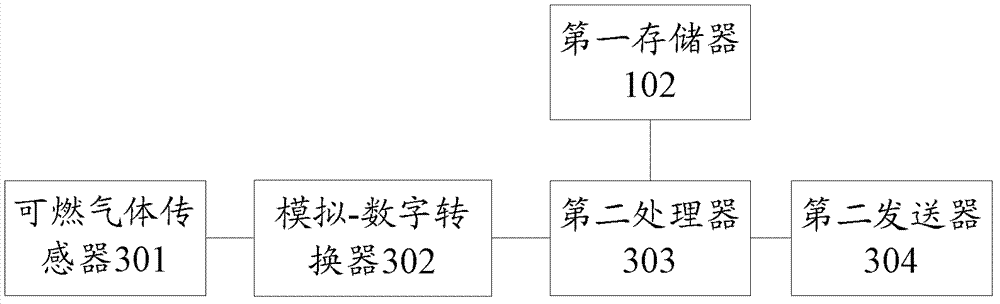

[0057] image 3 for figure 2 Another schematic diagram of the device shown. image 3 In the device shown and figure 2 The same part is image 3 Not shown in, where image 3 The device shown also includes:

[0058] The combustible gas sensor 301 is used to monitor the concentration of combustible gas around the liquefied petroleum gas cylinder, and generate an analog signal of concentration information;

[0059] The analog-digital converter 302 is used to convert an analog signal of concentration information into a digital signal of concentration information;

[0060] The second processor 303, connected to the first memory 102 and the analog-digital converter 302, is used to generate a second monitoring signal including the concentration information and identification information of the liquefied petroleum gas cylinder;

[0061] The second transmitter 304 is connected to the second processor 303 and is configured to send the second monitoring signal.

[0062] In this embodiment, prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com