Automatic basin fall positioning mechanism

A technology of positioning mechanism and drop basin, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of single working structure, easy deformation, and the conveyor belt cannot guarantee positioning at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

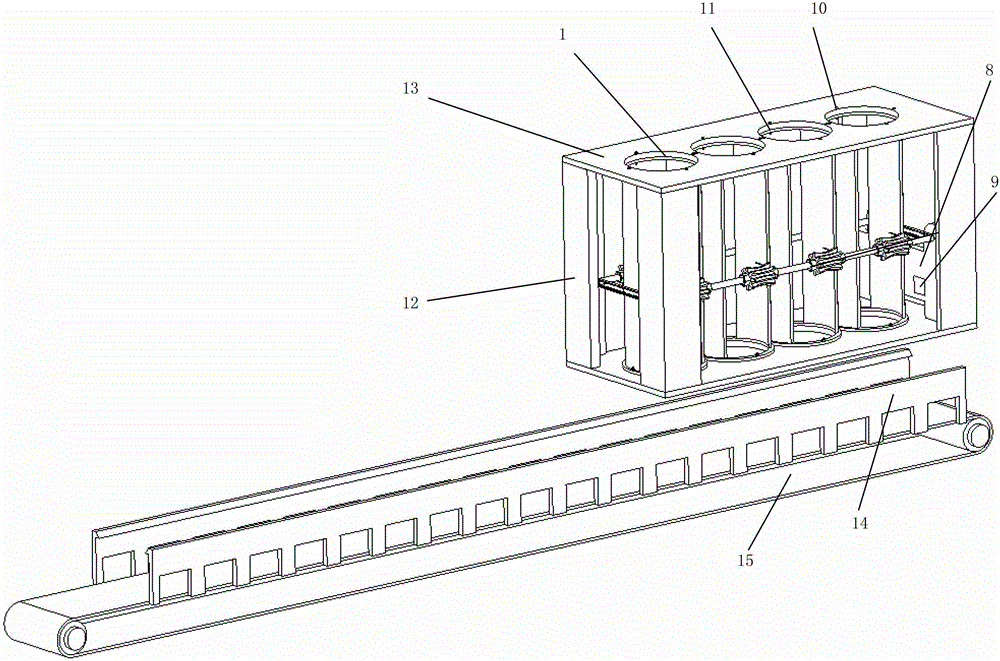

[0025] The present invention will be further described below in conjunction with accompanying drawing:

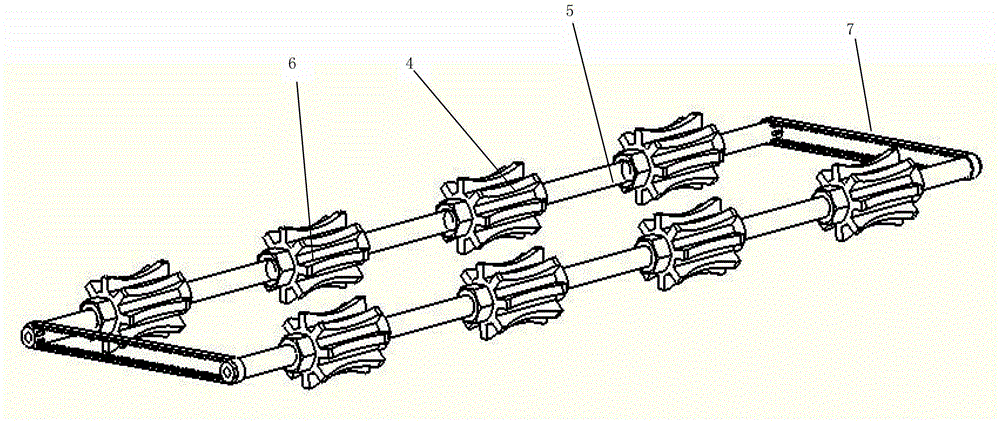

[0026] Such as figure 1 As shown, this example includes a retaining ring 1, a retaining piece 2, a block 3, a toggle block 4, a rotating shaft 5, a clamping hex nut 6, a timing belt 7, a fixing plate 8, a rotating shaft motor 9, a fixing hex nut 10, and a fixed Hex bolt 11, support frame 12, outer plate 13, auxiliary plate 14, conveyor belt 15. Two retaining rings 1 are connected with two retaining pieces 2 to form a cylinder, which are arranged sequentially; the retaining block 3 is installed on the inner surface of the retaining plate 2; the toggle block 4 is connected in series by the rotating shaft 5, and is installed in the cylinder according to the number of cylinders. The two sides of the cylinder and the position parallel to the block 3 are fixed by clamping hexagonal nuts, and the timing belt 7 is loaded with two rotating shafts 5 at both ends, and the fixing is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com