Link plate type high-temperature automatic constant weight feeder

A quantitative feeder and chain plate technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of difficult to guarantee accuracy, high cost, high maintenance intensity, etc., to ensure quality, ensure quality, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

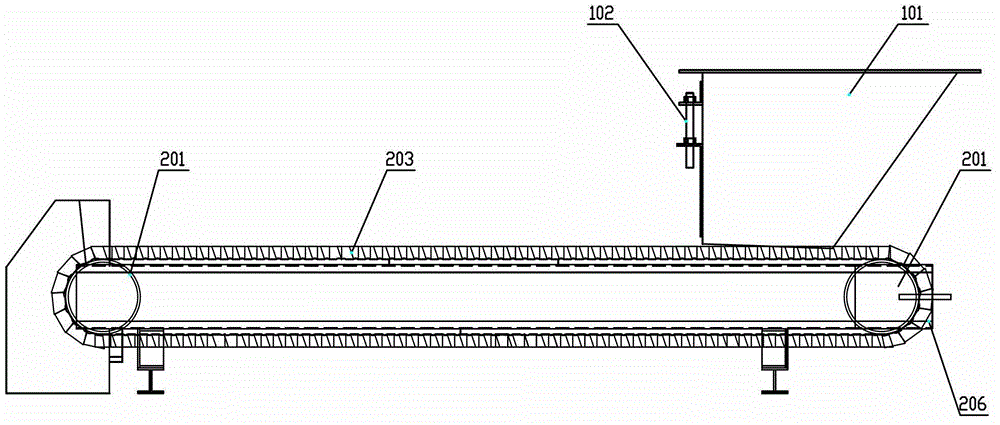

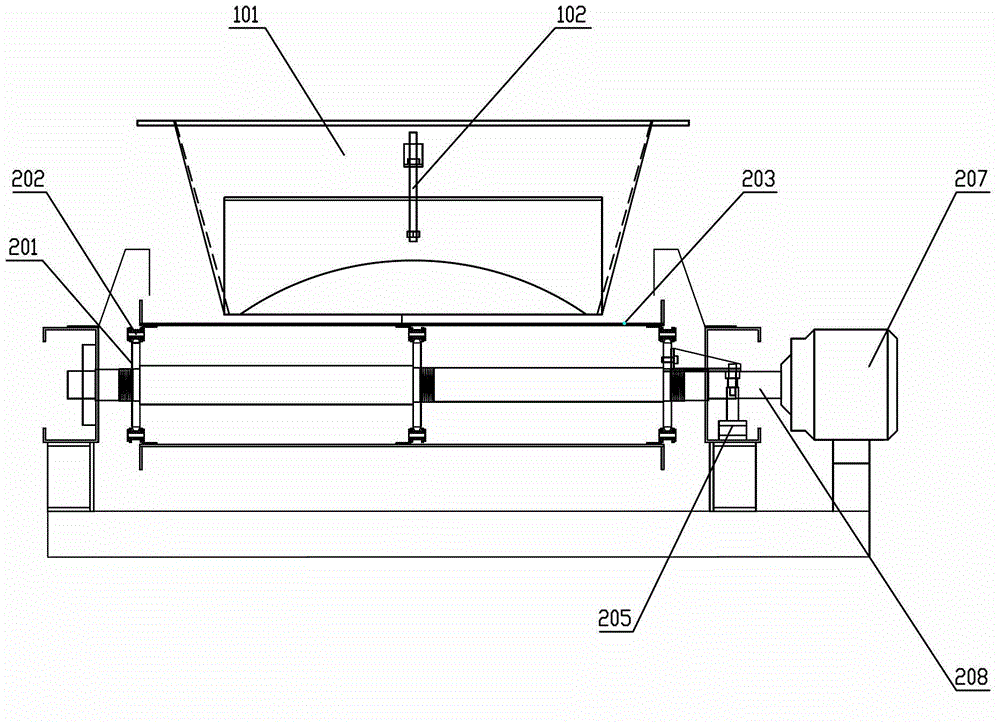

[0018] Such as figure 1 , figure 2 , Figure 3-Figure 6 As shown, the present invention mainly includes a feed hopper, a conveying control metering device, a cleaning device, and a program control system. The feed hopper is composed of a main body 101 and a gate valve 102, thereby adjusting the height of the material.

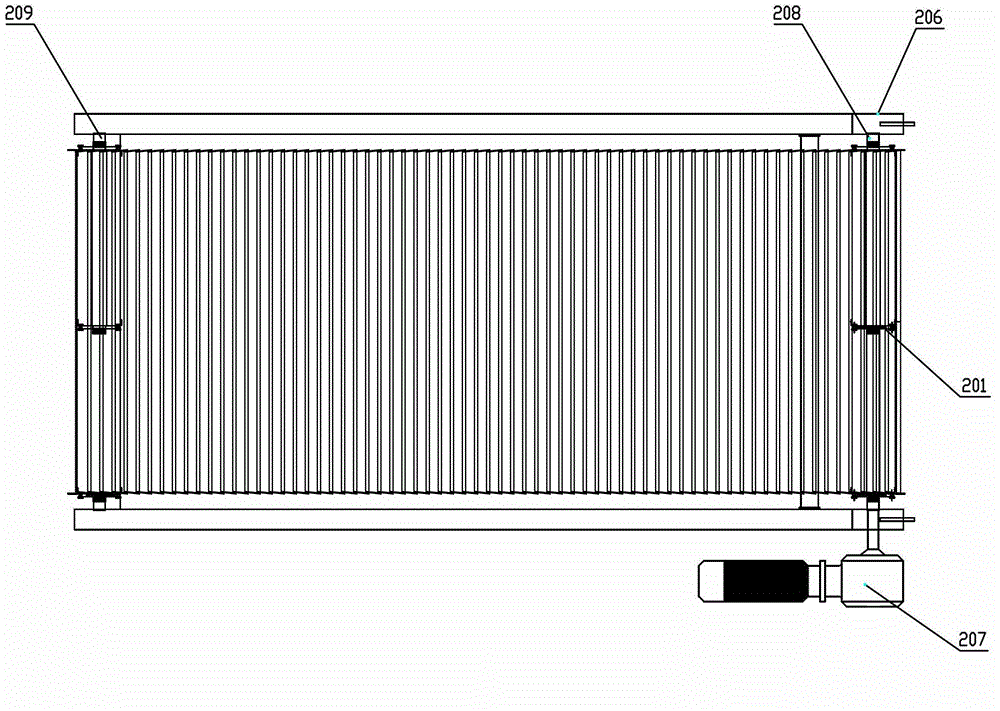

[0019] The conveying control metering device 2 is composed of a sprocket 201, a single-sided flap chain 202, a chain plate 203, a guide rail 204, a sensor device 205, a tensioning device 206, a motor 207, a driving shaft 208, and a driven shaft 209.

[0020] The chain plate 203 of the conveying control metering device of the present invention is made of 40Cr, and the chain connection structure is designed as a double arc. The chain plates match each other, and the gap is less than 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com