Method for freely forging casing elevator for petroleum drilling and production

A technology of oil drilling and casing, applied in the direction of metal processing equipment, etc., can solve the problems of time-consuming and labor-intensive, complicated forging process, etc., and achieve the effect of reducing cost, simple tools and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

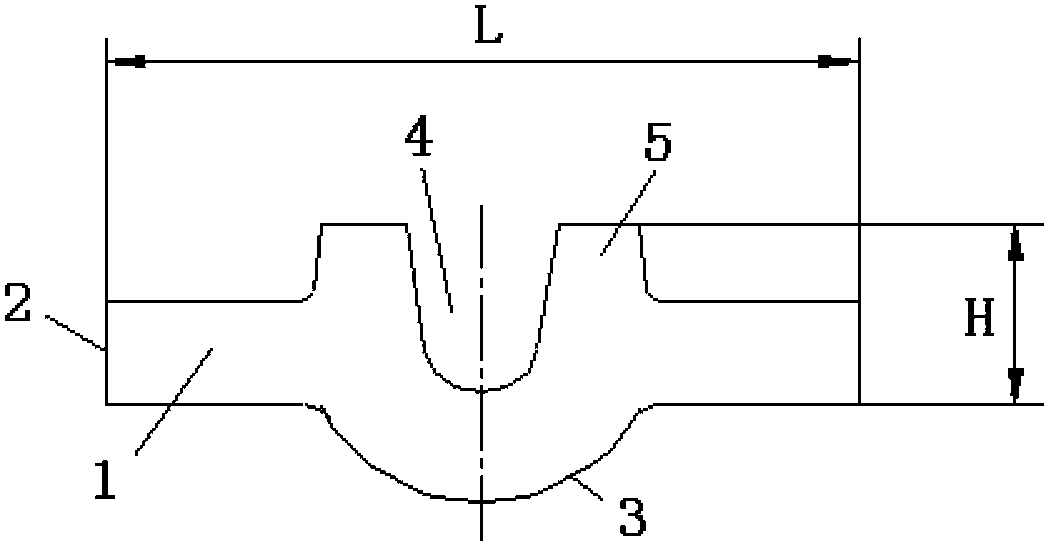

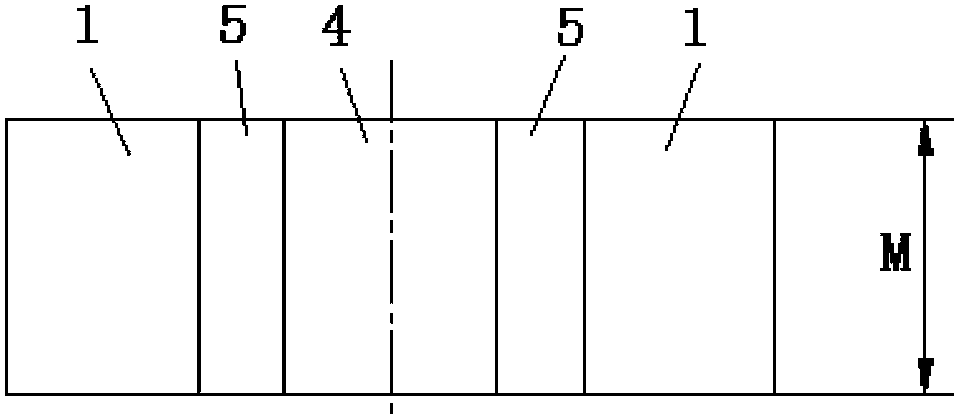

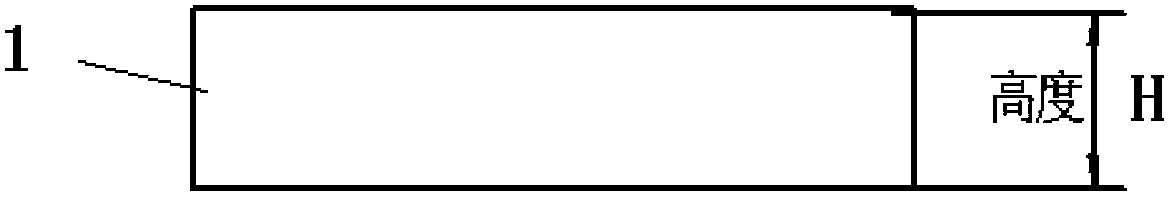

[0029] refer to figure 1 , figure 2 , the oil drill to be processed by the method of the present invention adopts a casing elevator structure, the section of the casing elevator main body is a U-shaped structure, the lower end of the casing elevator main body is a bow back 3, and the two upper ends of the casing elevator main body It is a boss 5, the inner cavity of the main body of the casing elevator is the middle groove 4, and there is a wing 1 on the outside of the facade on both sides of the main body of the casing elevator, and the outer end of each wing 1 is called the end 2.

[0030] The oil drill of the present invention adopts the free forging method of the casing elevator, and implements according to the following steps for the above-mentioned structure:

[0031] Step 1. Forging blanking: According to different casing elevator s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com