All-sealing screw-in preassembly-type medicine feeder

A fully sealed and pre-installed technology, applied in the field of medical devices, can solve problems such as pollution, contact between the dosing cartridge and the outside world, and the inability to achieve aseptic airtightness of the vial and dosing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

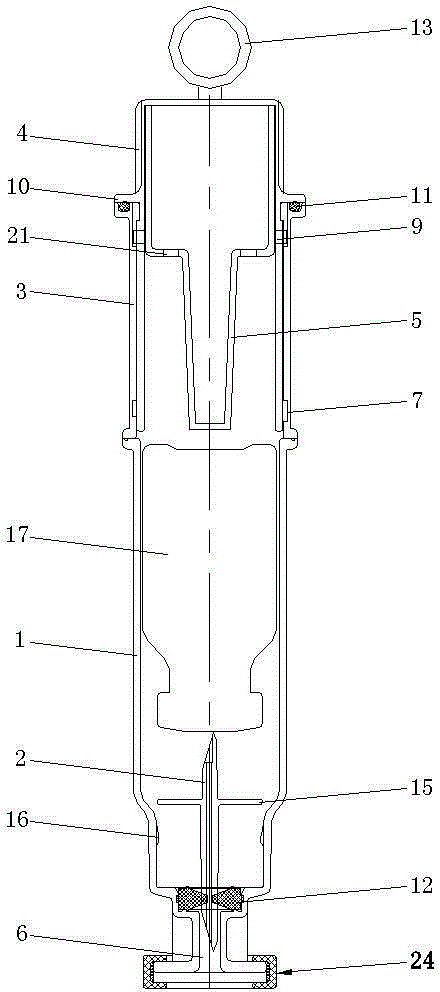

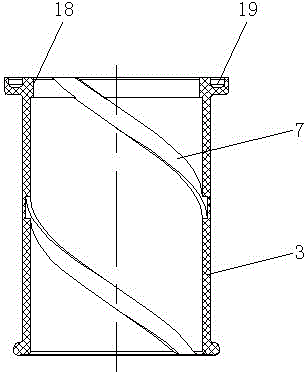

[0033] Such as figure 1 As shown, the fully sealed screw-in preinstalled dosing device includes a dosing cartridge 1, a dosing double needle 2, a guide sleeve 3, a rotating sleeve 4 and a push rod 5.

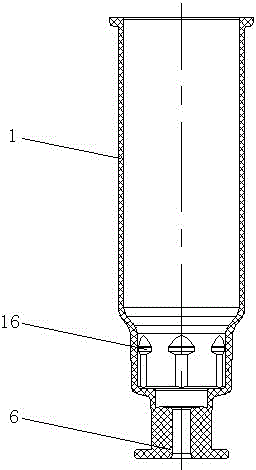

[0034] Among them, the structure of the cartridge is as follows: figure 2 As shown, the bottom of the dosing cartridge 1 is the interface connection end 6, and the inner wall of the interface connection end 6 is a constricted structure, which is more conducive to matching the interface size of the infusion container 14 (that is, the infusion soft bag or the infusion soft bottle). The inner wall of the dosing cartridge 1 and near the interface connection end 6 are provided with an annular rubber pad 12, and the dosing double needle 2 (the dosing double needle 2 in this embodiment adopts a cross needle, that is, the upper needle and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com