Rocker switch

A rocker switch and electrical connection technology, which is applied to the components of the flip switch/rocker switch, etc., can solve the problems of short service life and large wear and tear of the switch contact bridge, so as to reduce wear, prolong service life and reduce friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

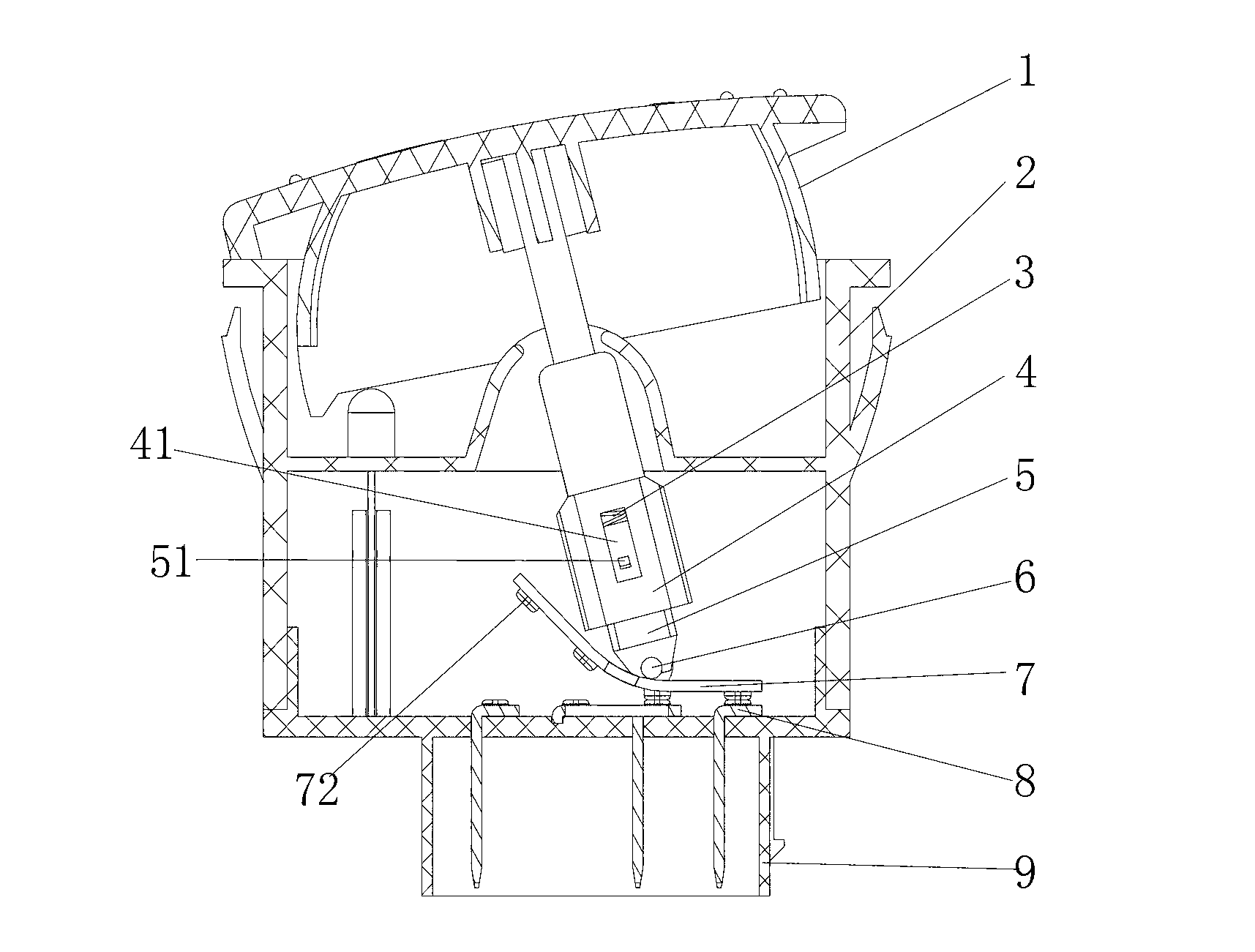

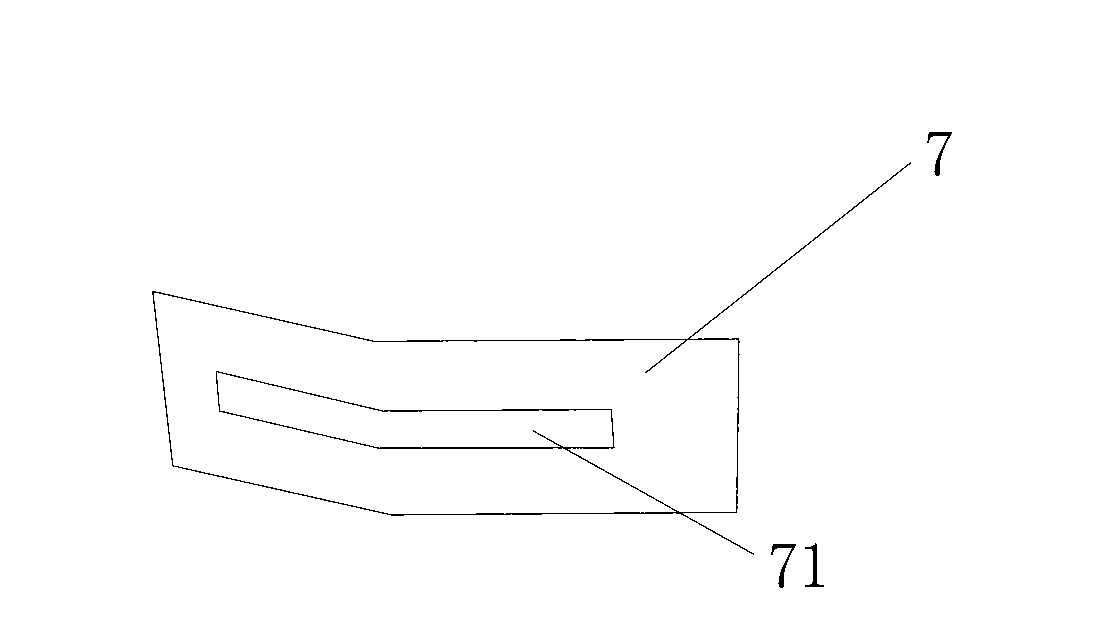

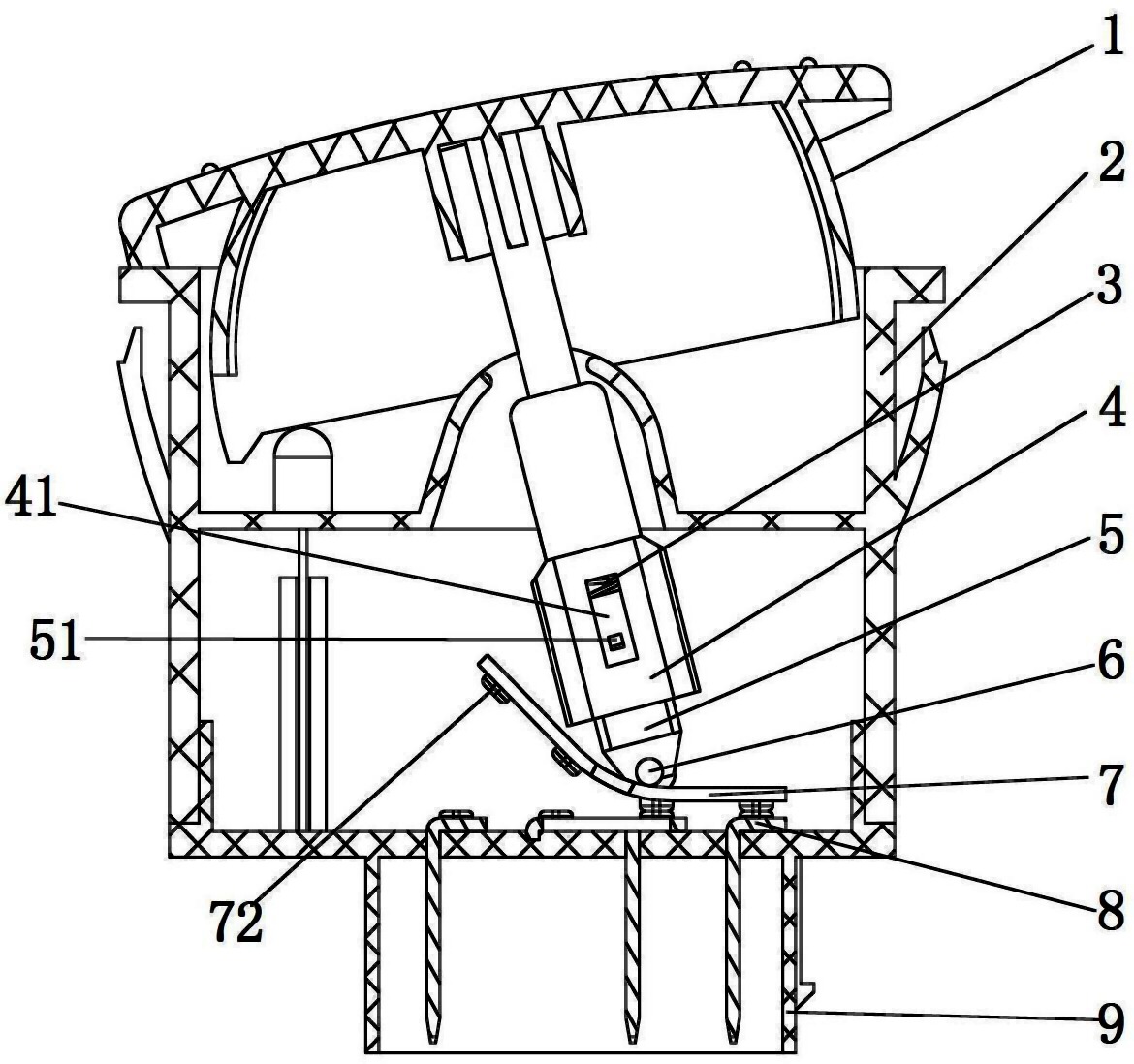

[0012] Such as figure 1 , figure 2 As shown, a rocker switch includes a button 1 , a base 9 , an electrical connection insert 8 fixed on the base 9 , a contact bridge 7 matched with the electrical connection insert 8 , and a housing 2 that fixes the base 9 . The button 1 is located at the end of the shell 2 away from the base 9 . A rotating block 4 is fixedly connected to the button 1, the lower half of the rotating block 4 is a column structure, the upper half of the transmission block 5 is sleeved in the lower half of the rotating block 4, and the upper end surface of the transmission block 5 is connected to the rotating block. A spring 3 that plays a return role is also provided between the inner walls of the block 4; the transmission block 5 can move in the axial direction, and a rectangular hole 41 along the spring expansion and contraction direction is opened on the side wall of the rotating block 4; The outer wall of 5 is provided with a boss 51 structure, and boss 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com