Epoxy modified polyurethane double-component grouting material for road engineering maintenance and preparation method thereof

A technology of epoxy modification and grouting material, applied in the field of epoxy modified polyurethane two-component grouting material and its preparation, can solve problems such as reducing the use of amine catalysts, achieve good compatibility, avoid hysteresis, Mild and efficient reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

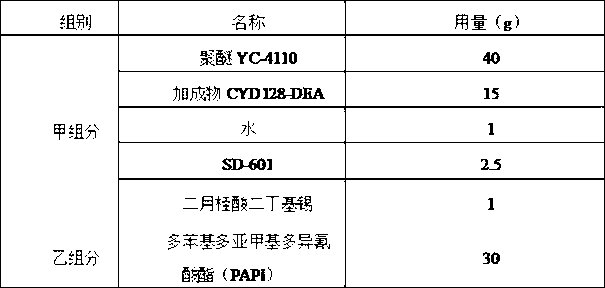

Embodiment 1

[0031]

[0032] The preparation method comprises the following steps:

[0033] Using diethanolamine and epoxy resin CYD-128 as raw materials, the molar ratio of diethanolamine:epoxy resin CYD-128 is 2:1, using methyl ethyl ketone as solvent, the reaction temperature is 80°C, and the reaction time is 4 hours. Epoxy resin CYD128-DEA adduct solution; distill the reaction product to remove the solvent under reduced pressure; add polyether YC-4110, foaming agent water, foam stabilizer SD-601 and catalyst dibutyltin dilaurate, stir and mix evenly After natural cooling to room temperature, the A component of the grouting material can be obtained; polyphenyl polymethylene polyisocyanate (PAPI) is used as the B component; the A and B components are mixed and stirred evenly, and the epoxy resin can be obtained. Modified polyurethane grouting material.

[0034] The volume began to expand after 30s, and the gel solidified after 90s; the mechanical properties test results showed that t...

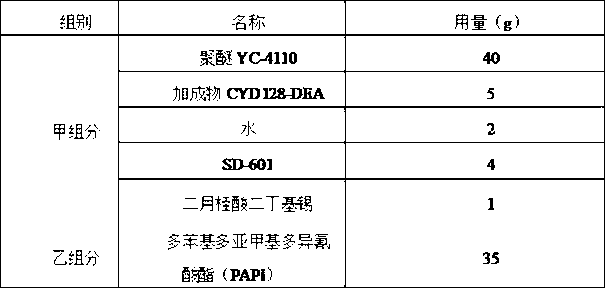

Embodiment 2

[0037]

[0038] The preparation method comprises the following steps:

[0039] Using diethanolamine and epoxy resin CYD-128 as raw materials, the molar ratio of diethanolamine:epoxy resin CYD-128 is 1:1, using methyl ethyl ketone as solvent, the reaction temperature is 80°C, and the reaction time is 4 hours. The solution of the epoxy resin CYD128-DEA adduct; the reaction product is distilled off under reduced pressure to remove the solvent; add a certain amount of polyether YC-4110, foaming agent water, foam stabilizer SD-601 and catalyst dibutyltin dilaurate, After stirring and mixing evenly, cool naturally to room temperature to get component A of the grouting material; polyphenyl polymethylene polyisocyanate (PAPI) is used as component B; components A and B are mixed and stirred evenly according to the above ratio, The epoxy-modified polyurethane grouting material can be obtained.

[0040] The volume began to expand after 40s, and the gel solidified after 100s; the mechan...

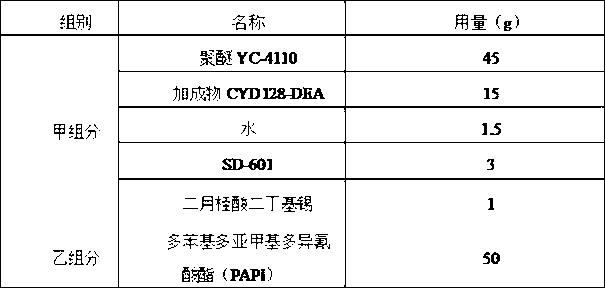

Embodiment 3

[0043]

[0044] The preparation method comprises the following steps:

[0045] Using diethanolamine and epoxy resin CYD-128 as raw materials, the molar ratio of diethanolamine:epoxy resin CYD-128 is 1.5:1, using methyl ethyl ketone as solvent, the reaction temperature is 80°C, and the reaction time is 3 hours. The solution of the epoxy resin CYD128-DEA adduct; the reaction product is distilled off under reduced pressure to remove the solvent; add a certain amount of polyether YC-4110, foaming agent water, foam stabilizer SD-601 and catalyst dibutyltin dilaurate, After stirring and mixing evenly, cool naturally to room temperature to get component A of the grouting material; polyphenyl polymethylene polyisocyanate (PAPI) is used as component B; components A and B are mixed and stirred evenly according to the above ratio, The epoxy-modified polyurethane grouting material can be obtained.

[0046] The volume began to expand after 50s, and the gel solidified after 120s; the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com