Pressure measurement tail rake for wing section tunnel test

A technology of wind tunnel test and pressure measurement tail rake, which is applied in the field of airfoil aerodynamic performance wind tunnel test, which can solve the problems of the deviation of the total pressure airfoil drag coefficient result and the inability to capture the airflow angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] This embodiment is a pressure measuring mechanism used to determine the direction of incoming flow.

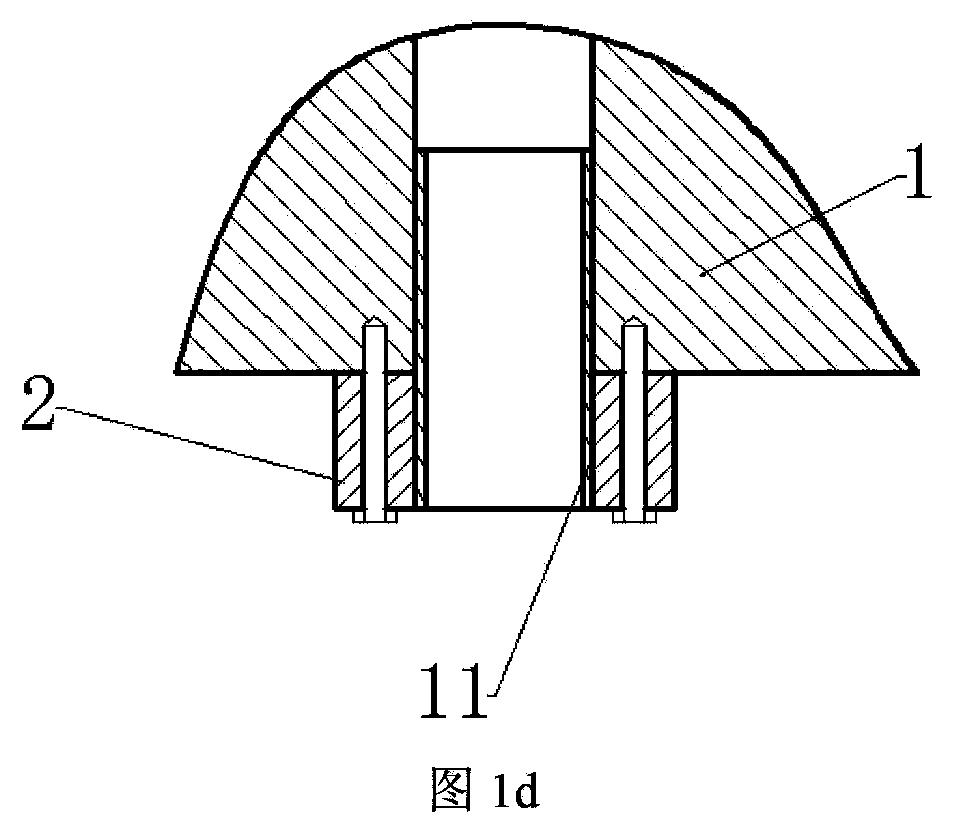

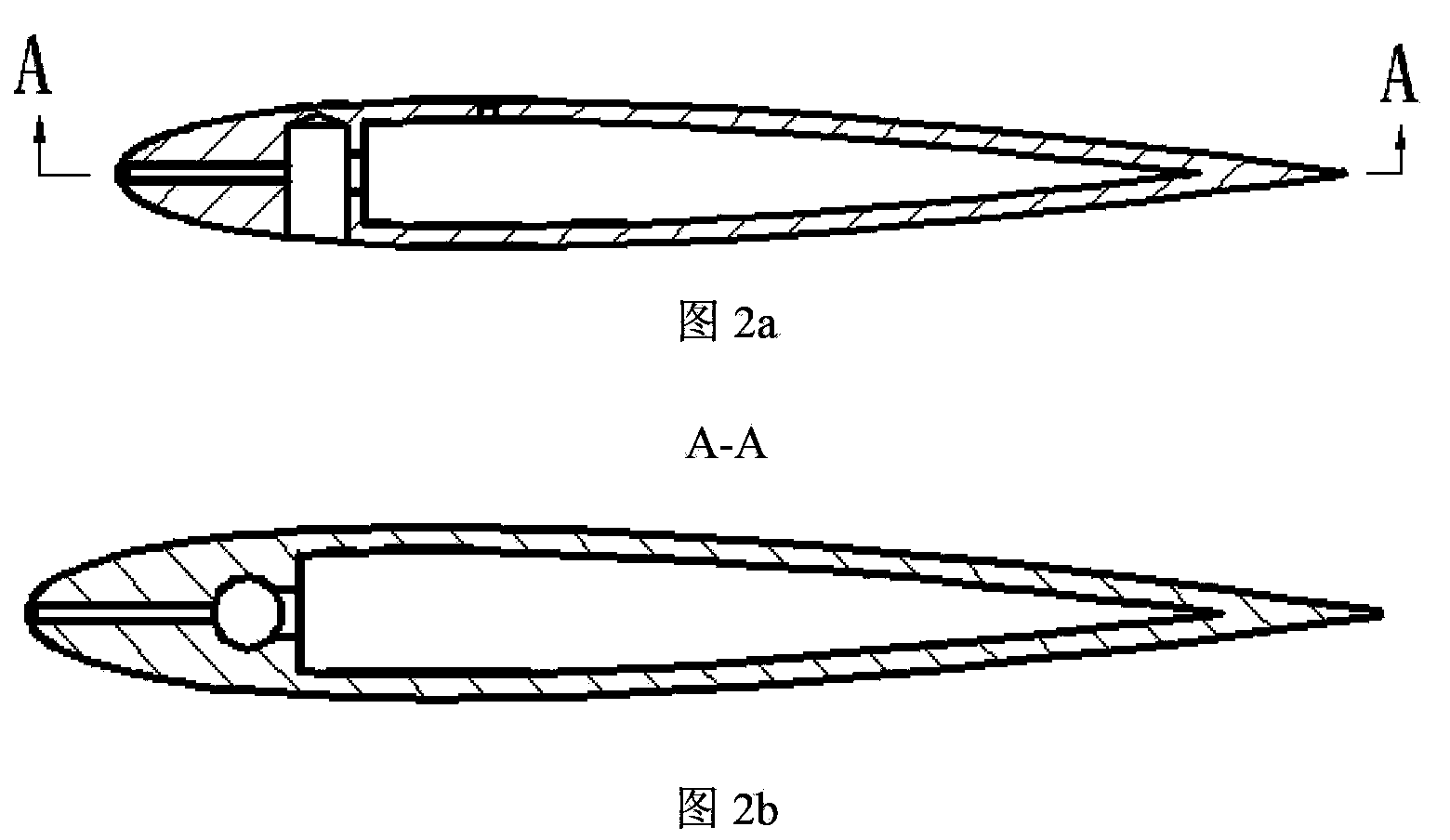

[0035] This embodiment includes a beam 1, a bracket 2, and 20 pressure measuring cones 3, and a rotating shaft 5 matching the 20 pressure measuring cones 3, an angle sensor 4, an eccentric ball bearing 8, a gland 6, a total pressure pipe 9, a static pressure Tube 10 and hollow pin 11.

[0036] Both ends of the beam 1 are fixed on the top of the bracket 2 . A plurality of pressure measuring cones 3 are installed on the upper surface of the beam 1, the number of the pressure measuring cones is determined according to the range and measurement accuracy of the test model wake area, so that the test model wake area is between the pressure measuring cones at the most ends. In this embodiment, the width of the wake area of the test model is 300mm, and the number of pressure measuring cones is 20. Each of the pressure measuring cones 3 is installed above the beam 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com