Friction device for external rail of rotary platform

A technology of rotating platform and friction device, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of high repair cost, high manufacturing cost, difficult to repair, etc., and achieves small deviation error, stable rotation, and structure. Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

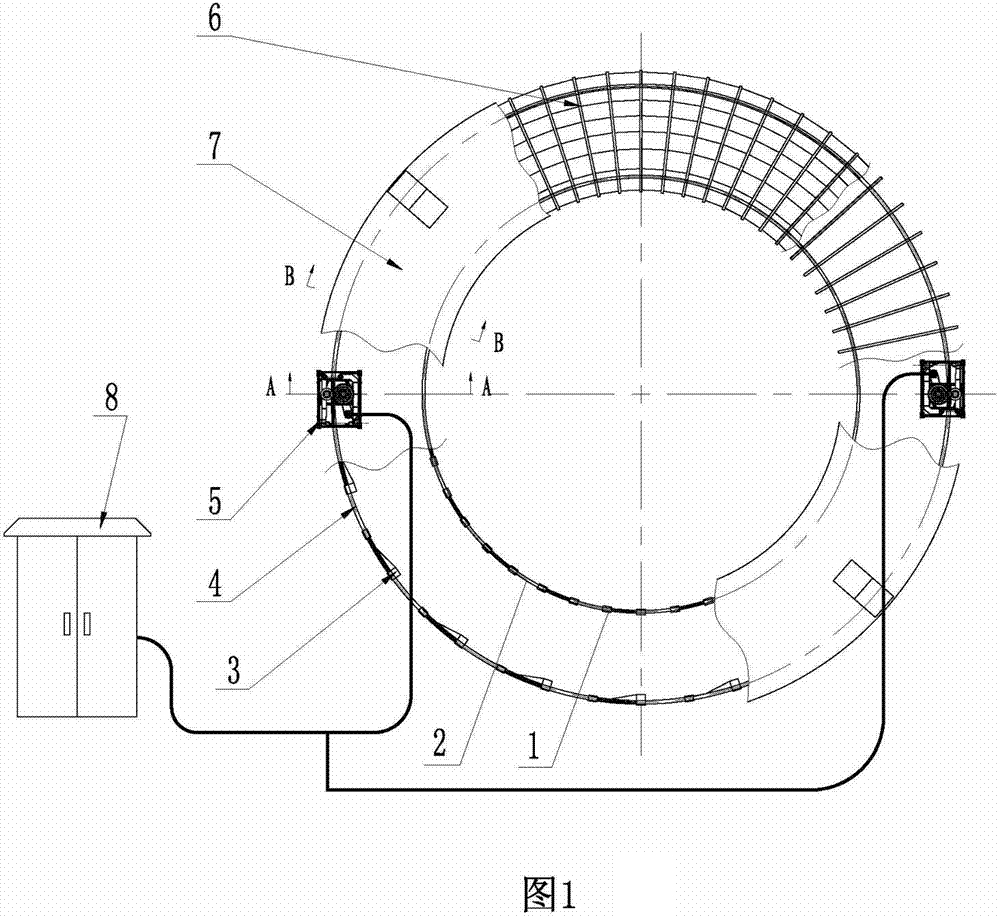

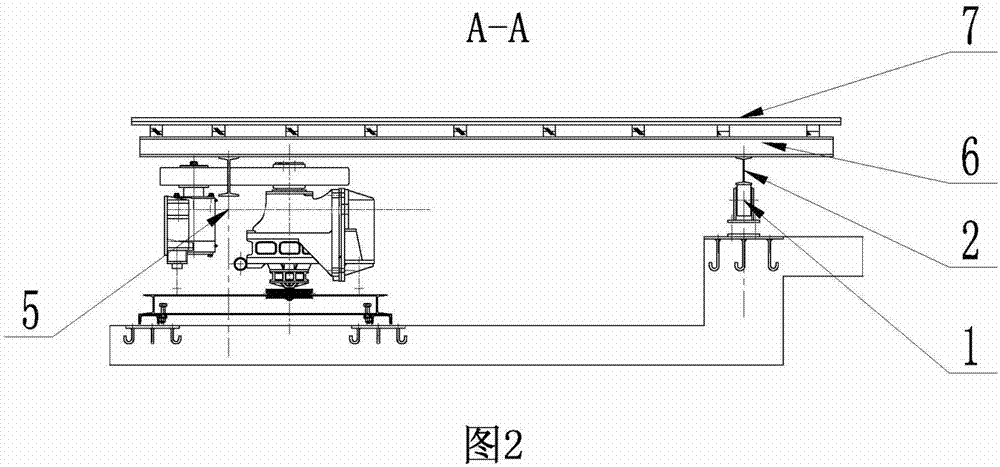

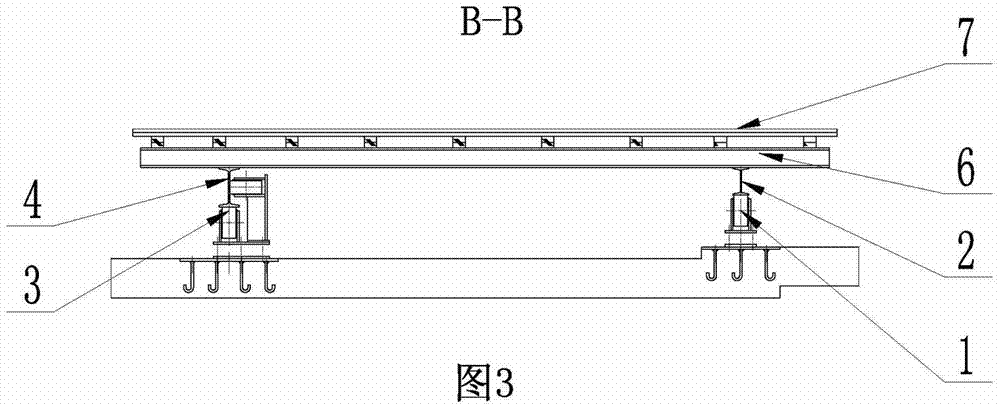

[0020] Such as figure 1 , figure 2 , image 3 As shown, the outer rail friction device of the rotary platform of the present invention is an improvement on the existing rotary platform technology. The outer rail friction device of the rotating platform of the present invention includes a rotating platform skeleton 6 and an annular inner rail 2 and an outer rail 4 fixed on the lower surface of the rotating platform skeleton 6, and is attached to the lower surface of the inner rail 2 and anchored on the ground foundation The inner support wheel set 1. The lower surface of the outer track 4 of the present invention fits and connects several centripetal support wheel sets 3 anchored on the ground foundation. The web of the outer rail 4 is connected to a friction drive mechanism 5 .

[0021] Such as Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, two friction drive mechanisms 5 are provided symmetrically, and each friction drive mechanism 5 includes a friction dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com