Inner-film bag with vertically-fitted adhesive tapes

A tape and film bag technology, applied in the field of container bags, can solve the problems of easy generation of air flow, affecting the usage, affecting the quality of materials in the bag, and avoiding moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

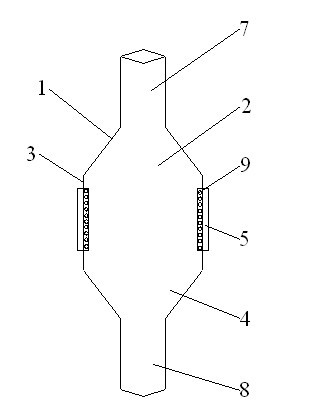

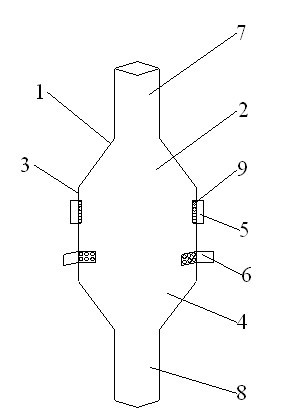

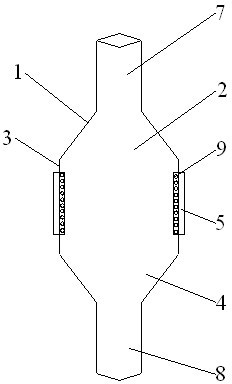

[0016] see Figure 1 to Figure 2 , the embodiment of the present invention includes:

[0017] A kind of upper and lower fitting adhesive tape inner film bag, comprising: inner bag body 1, inner bag body 1 includes interconnected top panel 2, side block 3 and bottom panel 4, the slope structure of top panel 2 and bottom panel 4 and the outer bag The fit setting between the inner and outer bags reduces the connection gap between the inner and outer bags and avoids the leakage of materials.

[0018] There is a feed pipe 7 vertically above the top panel 2, a discharge tube 8 vertically below the bottom panel 4, tapes are connected to the side frames...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com