Slowly-dropping escape device

A slow-descent escape device and escape device technology, applied in life-saving equipment, building rescue, etc., can solve the problems that the descending speed cannot be effectively controlled at the end of the descent, the performance of centrifugal friction damping is reduced, and the danger is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

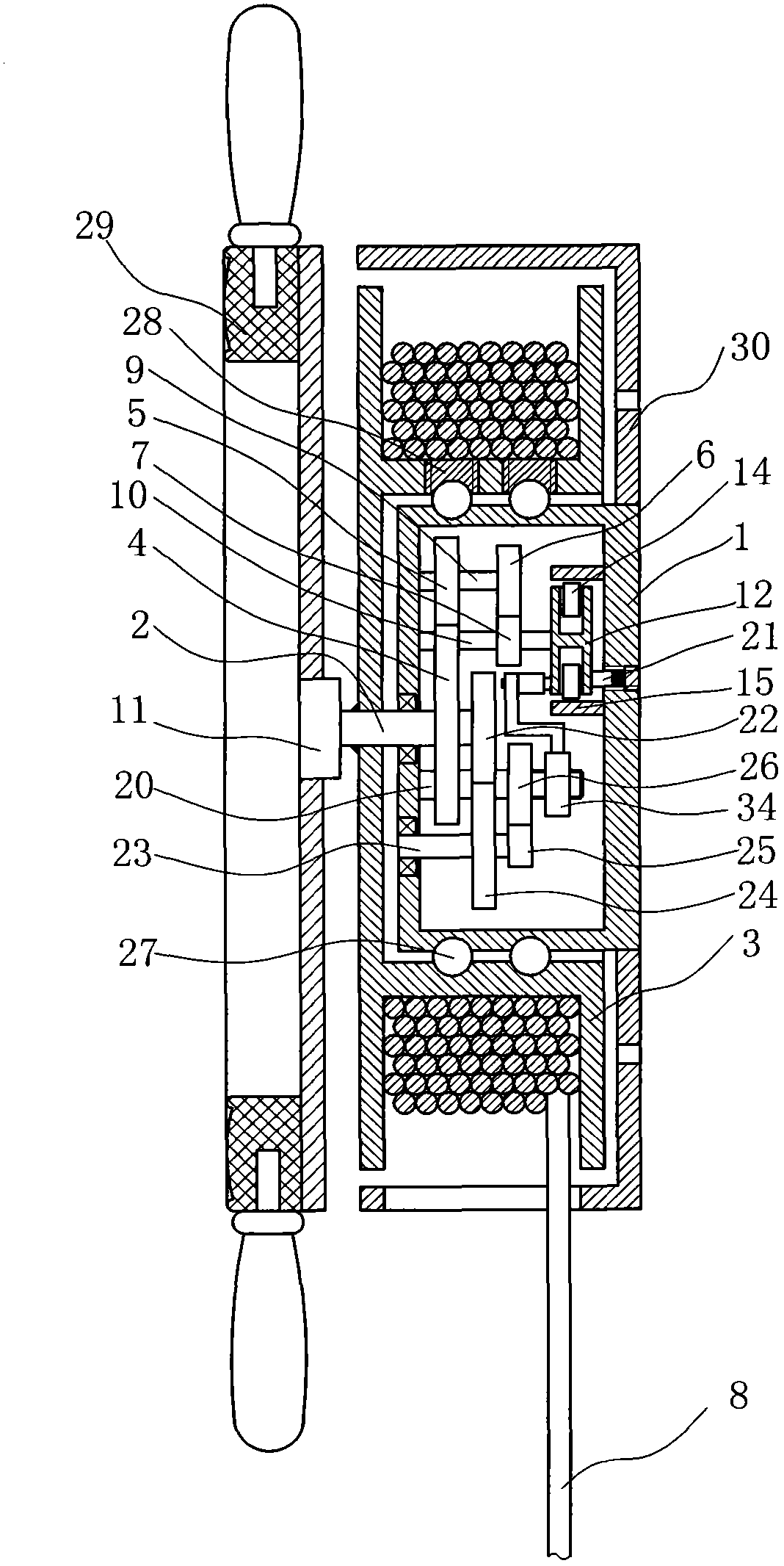

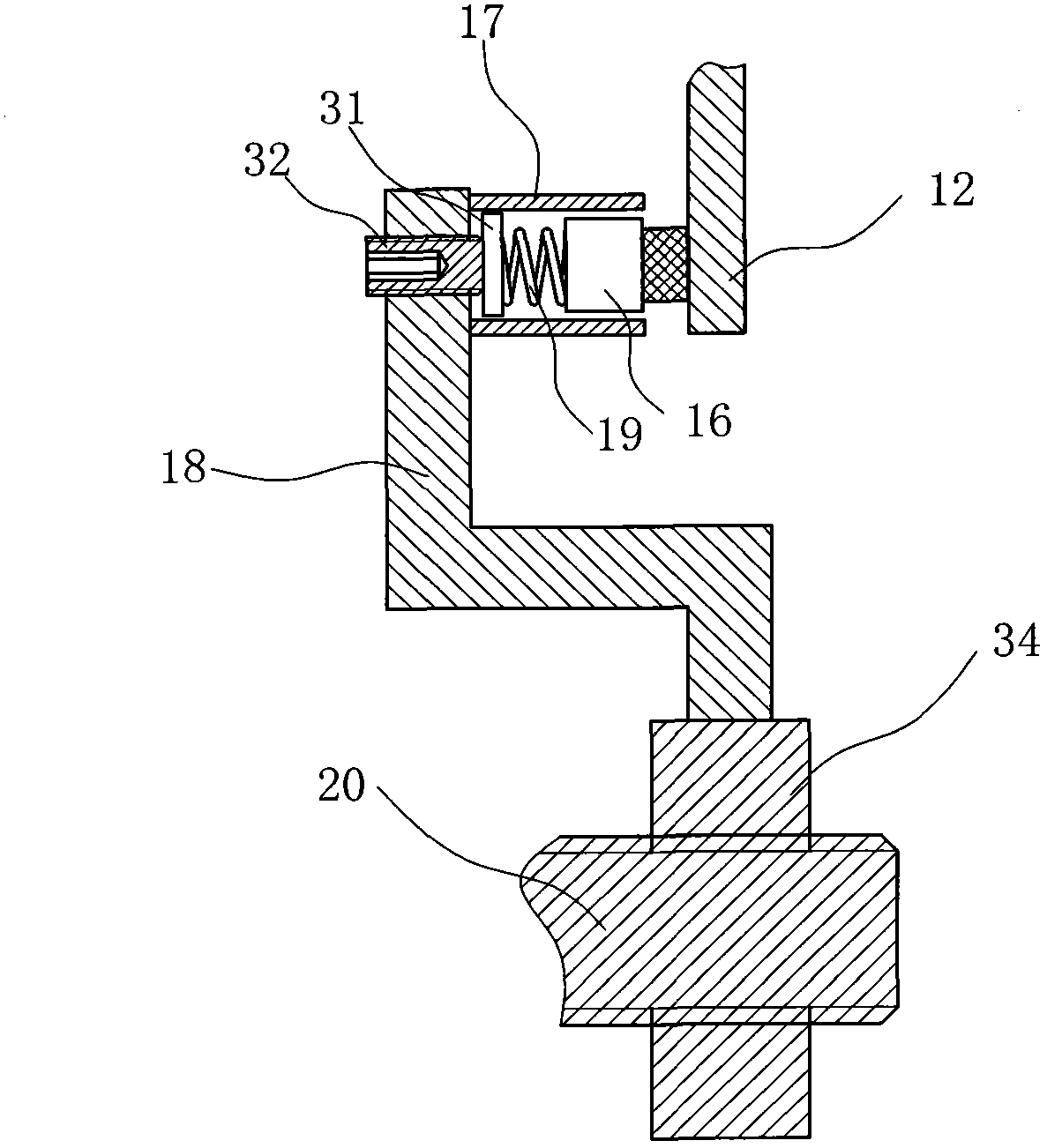

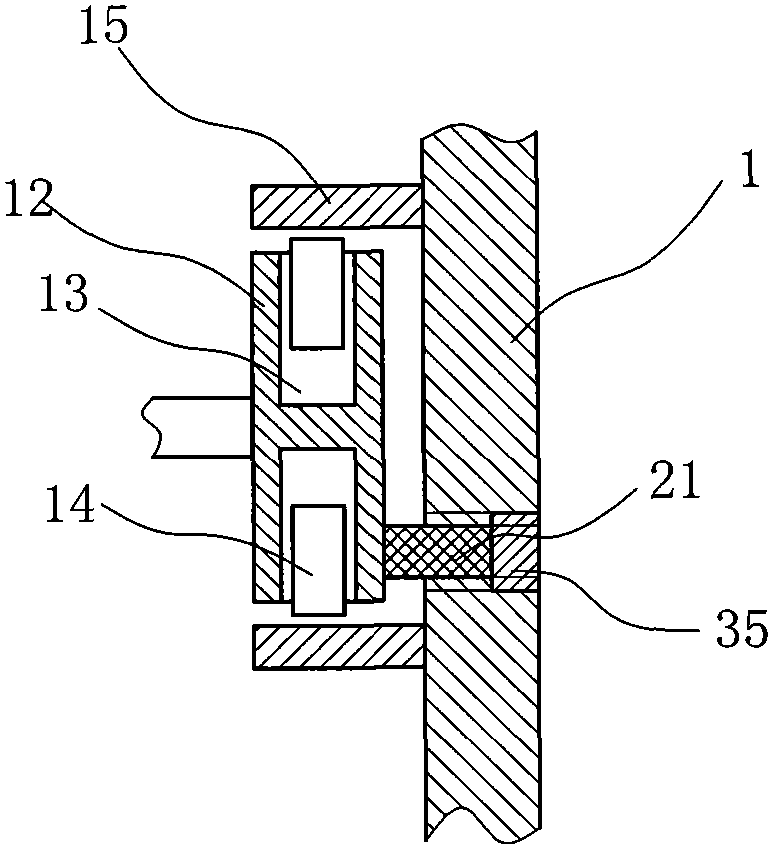

[0023] Such as figure 1 and figure 2 As shown, the slow descent escape device includes a base 30 on which a damping device housing 1 is installed, and the damping device housing 1 is a cylinder whose axis is perpendicular to the plane of the base 30. A central shaft 2 is installed in rotation on the damping device housing 1, and one end of the central shaft 2 protruding from the damping device housing 1 is fixedly installed with a cylindrical rope winding roller 3, and a lifesaving rope is wound on the rope winding roller 3 8. The rope winding roller 3 is rotatably set on the damping device housing 1, and the outer end of the rope winding roller 3 is equipped with a rope receiving device, and the damping device housing 1 and the rope winding roller 3 Ball grooves are arranged between the cover surfaces of the ball grooves, steel balls 27 are installed in the ball grooves, ball holes communicating with the ball grooves are arranged on the rope winding roller 3, and ball plugs...

Embodiment 2

[0030] Such as Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the rope-receiving steering wheel 29 is directly fixed on the rope winding roller 3, and the rope-receiving steering wheel 29 and the rope winding One-way clutches are no longer provided between the rollers 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com