Component mounting apparatus

A technology for installing machines and components, which is applied to electrical components, electrical components, etc., and can solve problems such as time-consuming, poor processing, and it is extremely difficult for users to change the operation sequence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

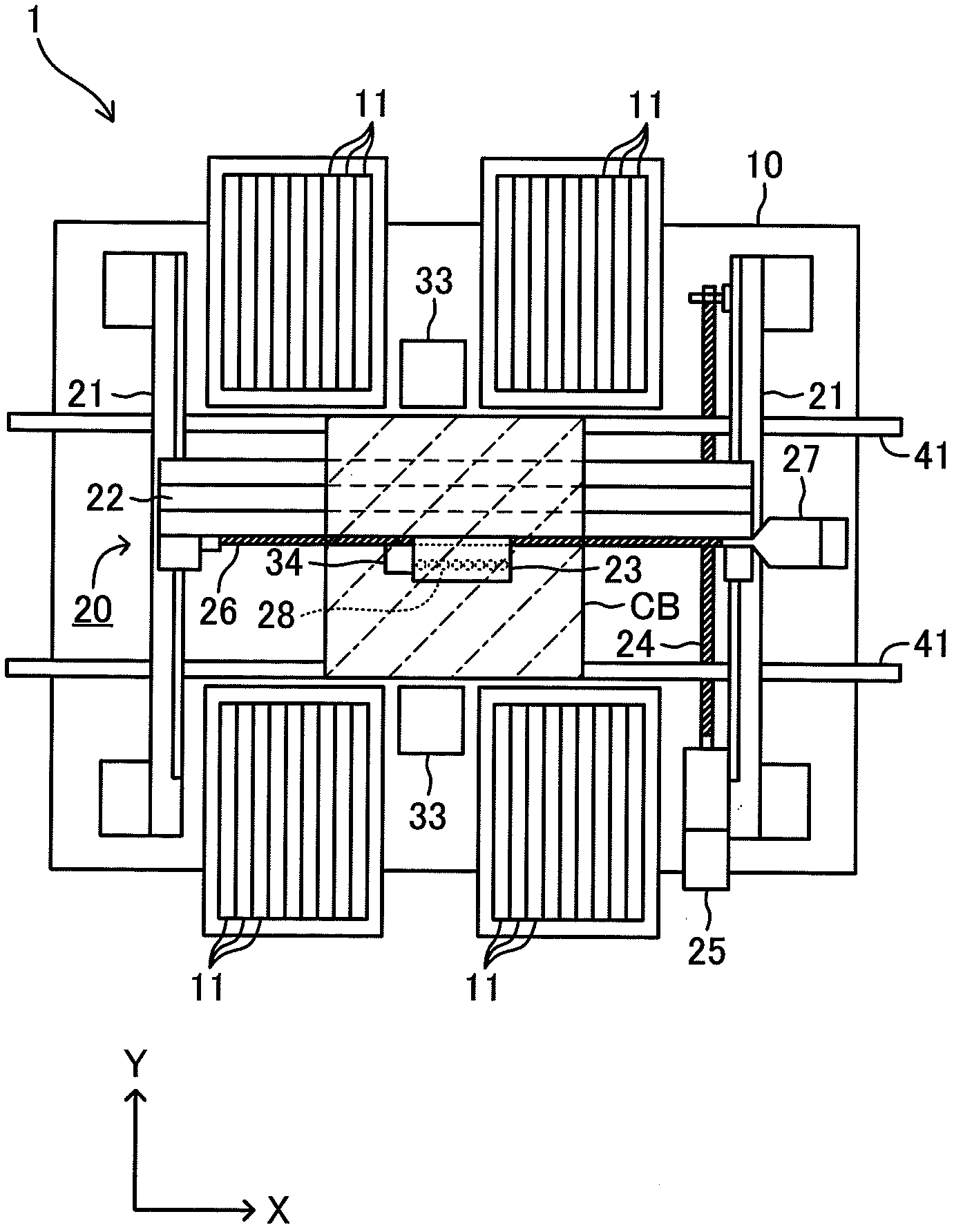

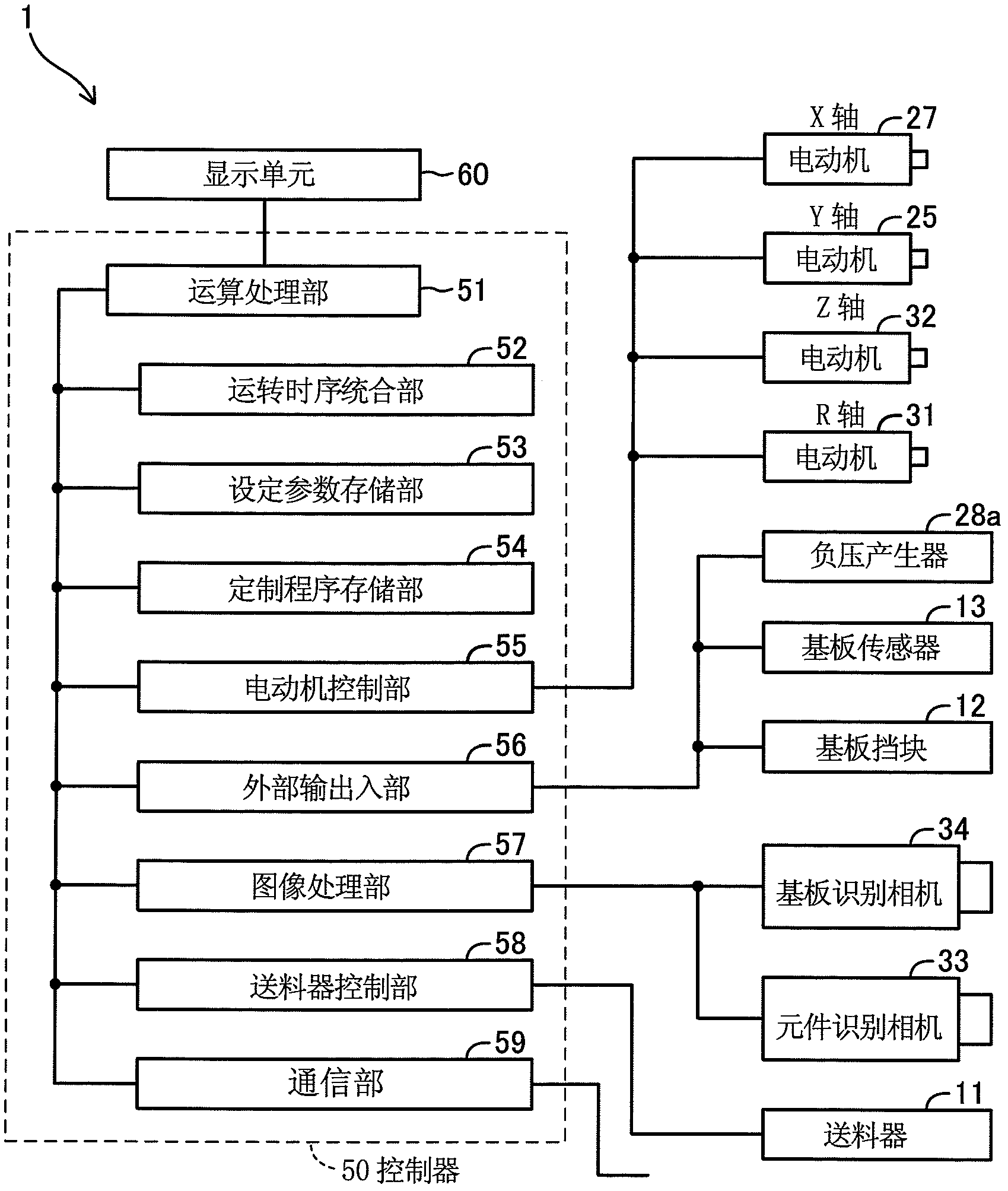

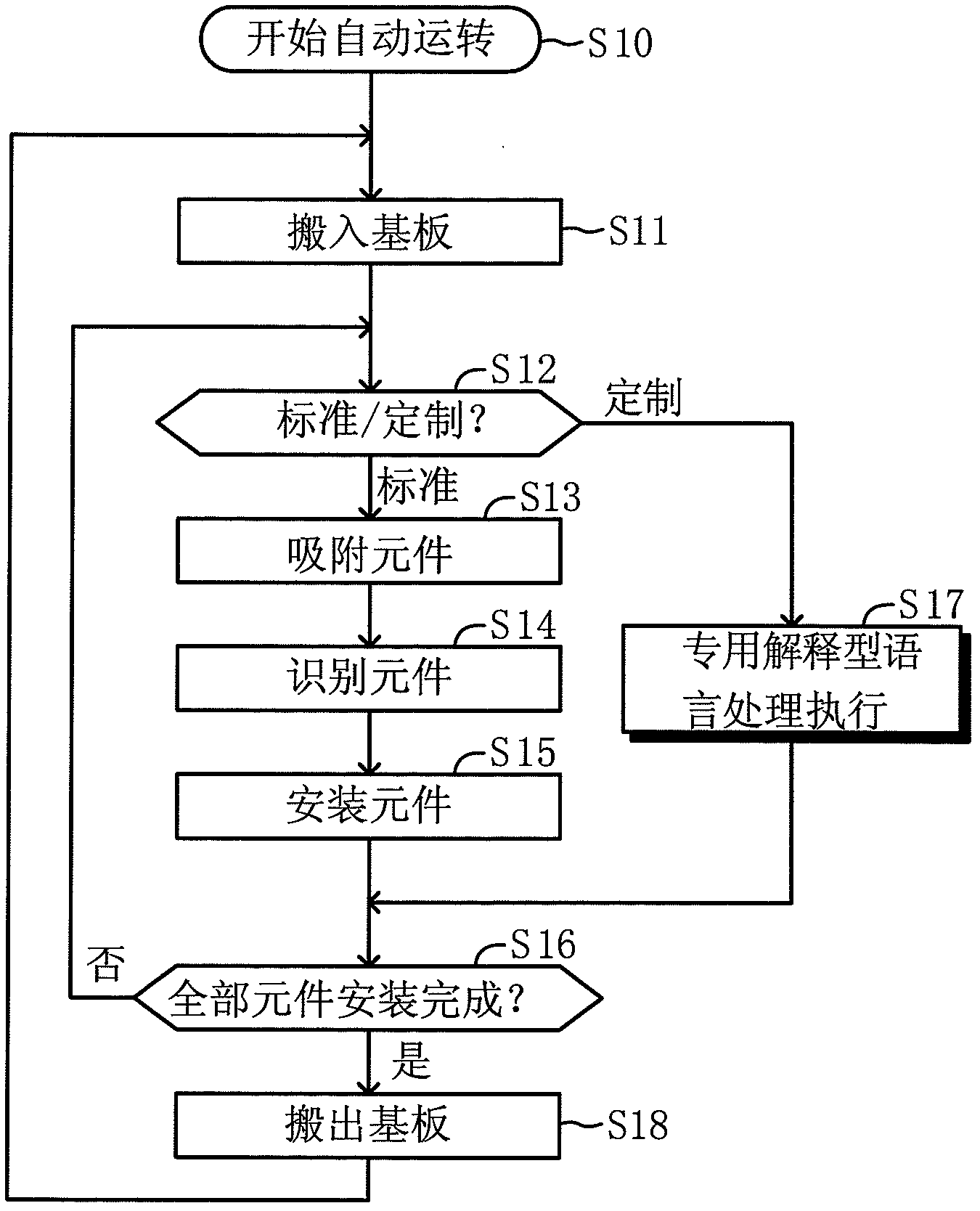

[0048] Next, a first embodiment of the present invention will be described. The structure of the component mounting machine 1 according to the first embodiment is the same as that described above. figure 1 , 2 have the same structure. In the first embodiment, the component mounting machine 1 includes Figure 4 "Specialized Interpreted Language Processing Execution Subroutines" of image 3 The operation sequence integration unit 52 of the operation sequence. The operation sequence integration unit 52 is written in a compiled language, and integrates a sequence for causing the component mounting machine 1 to repeatedly execute standard sequence operations basically including suction, recognition, and mounting of electronic components. The operation sequence integration unit 52 also determines the execution of the "dedicated interpreted language processing execution subroutine" during the repeated execution of the standard sequence operation. The "dedicated interpreted lang...

no. 2 Embodiment approach

[0070] Next, a second embodiment of the present invention will be described. The structure of the component mounting machine 1 according to the second embodiment is also the same as that described above. figure 1 , 2 have the same structure. This second embodiment includes Figure 4 "Specialized Interpreted Language Processing Execution Subroutines" of Figure 8 integrated processing of the operation sequence. In the present embodiment, the operation sequence integration process is also written in a compiled language to integrate the sequence for causing the component mounter 1 to repeatedly execute the standard sequence operations basically including the adsorption, recognition, and mounting of electronic components, and in the standard sequence In the repeated execution process of , the execution of the "dedicated interpreted language processing execution subroutine" is determined instead of each processing of adsorption, recognition, and mounting of electronic componen...

no. 3 Embodiment approach

[0084] Next, a third embodiment of the present invention will be described. The structure of the component mounting machine 1 according to the third embodiment is also the same as that described above. figure 1 , 2 have the same structure. This third embodiment includes Figure 4 "Specialized Interpreted Language Processing Execution Subroutines" of Figure 12 integrated processing of the operation sequence. In the present embodiment, the operation sequence integration process is also written in a compiled language to integrate the sequence for causing the component mounter to repeatedly execute the standard sequence operations basically including the adsorption, recognition, and mounting of electronic components, and in the standard sequence In the repeated execution process, the execution of the "dedicated interpreted language processing execution subroutine" is determined as needed before or after each processing of adsorption, recognition, and mounting of electronic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com