Electrical connector assembly

A technology of electrical connectors and components, which is applied in the direction of network connectors, connections, components of connection devices, etc., can solve the problems of insufficient space and detachment from the docking part, and achieve good results and good anti-electromagnetic interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

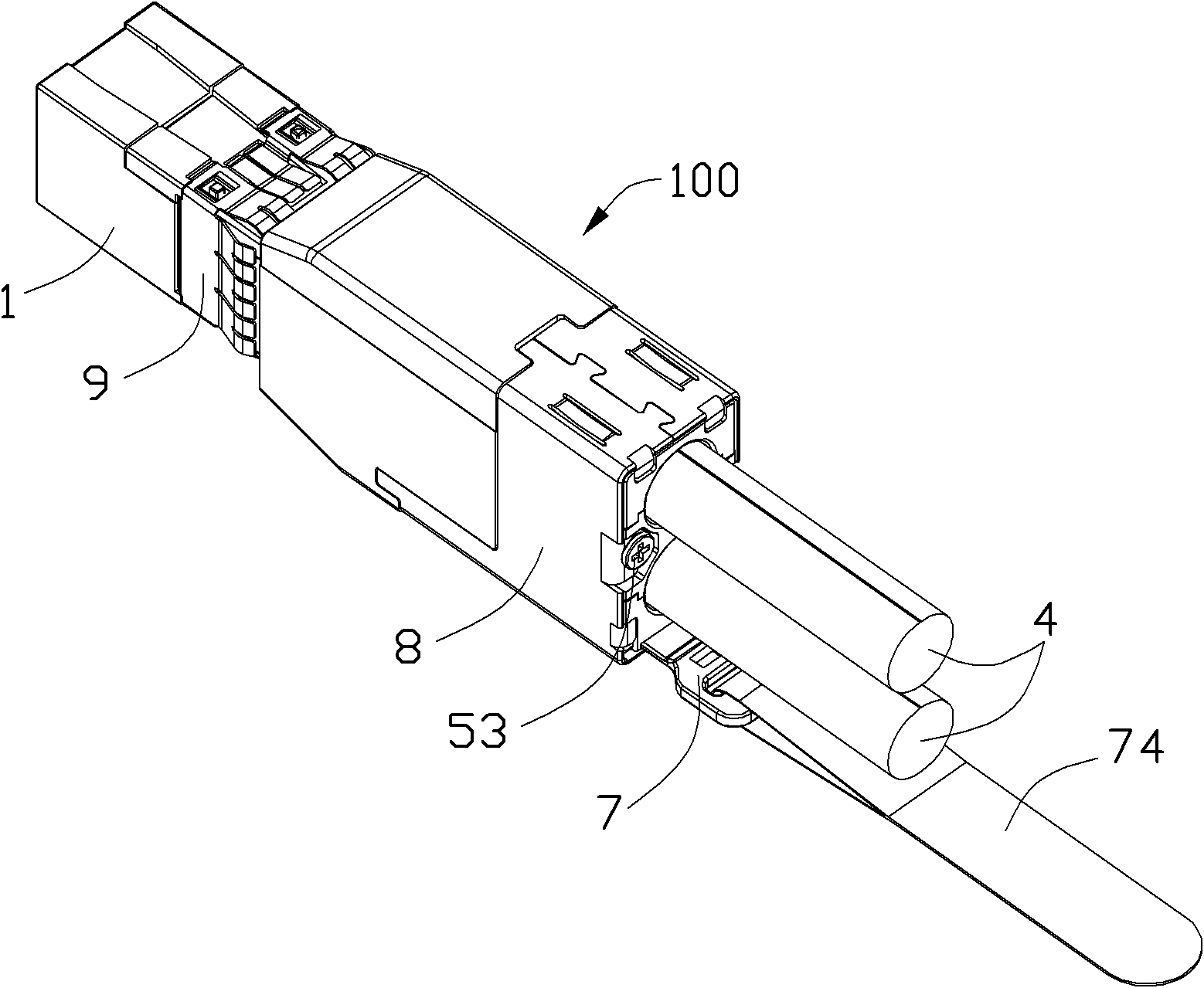

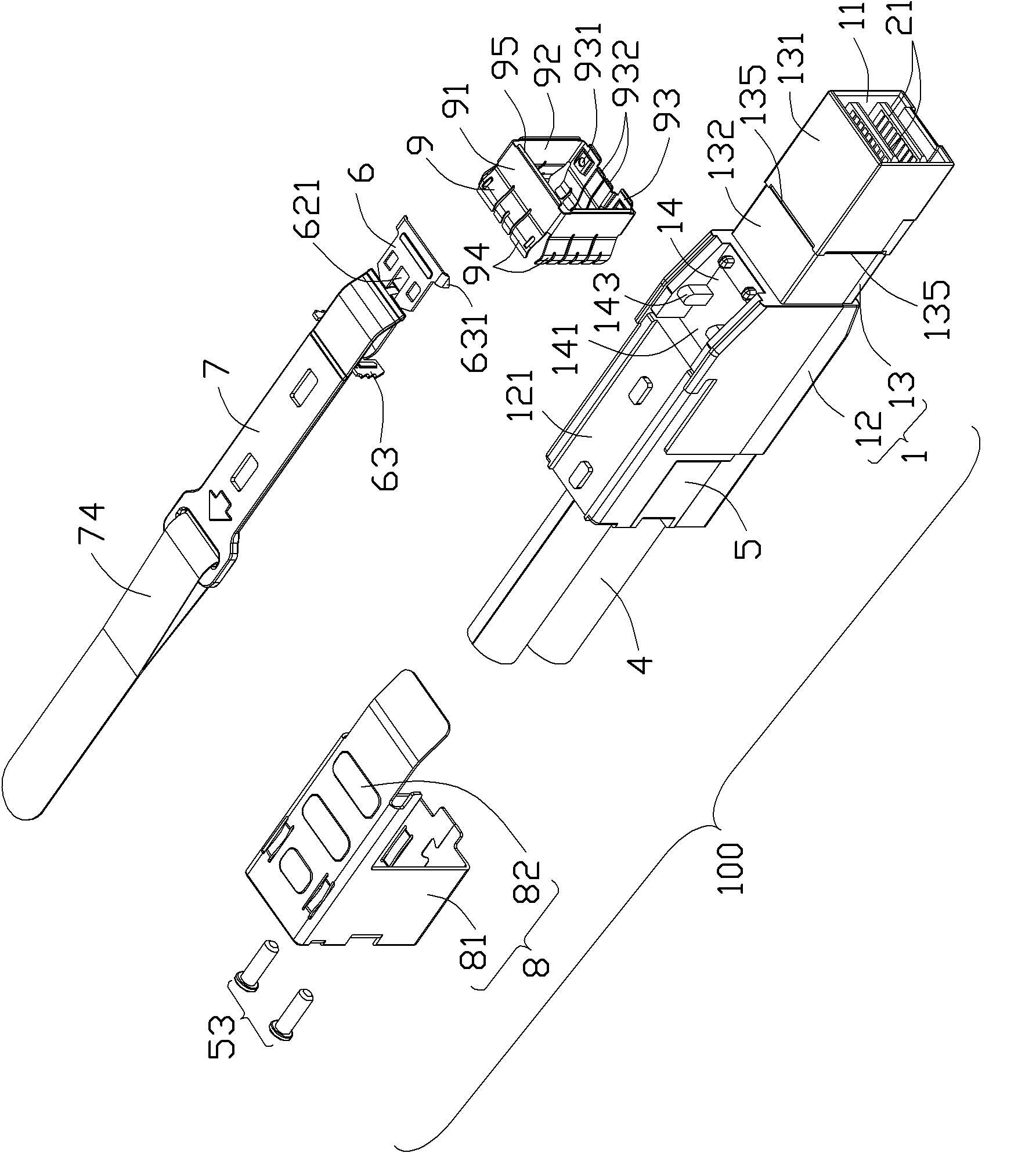

[0024] see Figure 1 to Figure 4 and combine Figure 7 to Figure 10 The electrical connector assembly 100 of the present invention includes a main body 1 having a receiving space 11, two printed circuit boards 2 arranged in parallel and spaced apart in the receiving space 11 of the main body 1, arranged between the two printed circuit boards 2 and The partition plate 3 that is positioned and matched with the body 1, and the two cables 4 that extend into the body 1 and are electrically connected to the rear ends of the two printed circuit boards 2 are assembled in the body 1 and connect the two cables. 4 spaced apart stress relief blocks 5 . In addition, the electrical connector assembly 100 also includes a locking device assembled on the body 1, the locking device includes a locking piece 6 and a puller 7 connected to each other, and the puller 7 is placed on the locker 6 Above, the horizontal movement of the puller 7 can drive the vertical movement of the front end of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com