Suction jig

A fixture and product technology, applied in the direction of layered products, lamination auxiliary operation, lamination, etc., can solve the problems that affect the quality of the attached surface, the attachment of large areas is not easy to be flat, the surface is prone to bubbles, wrinkles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

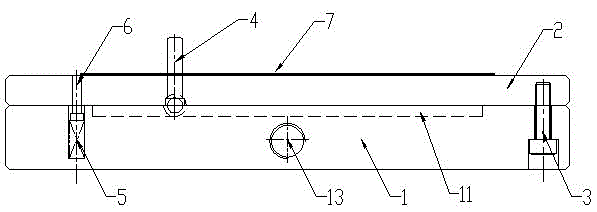

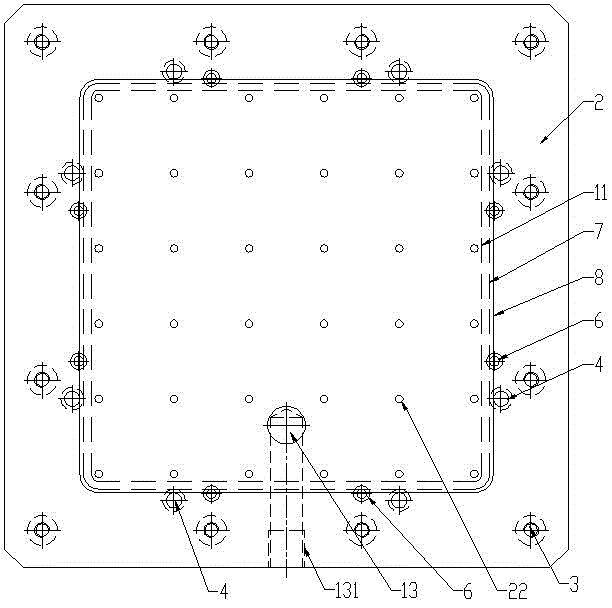

[0023] Such as figure 1 , figure 2 As shown, the suction fixture of the present invention includes a lower mold 1 with the same outer frame shape and an upper mold 2 placed on the lower mold 1 . The product 7 and its attachments are all placed on the upper mold 2 . The sticker can be a film or an adhesive tape 8 . The film or glued paper 8 attached on the product 7 is slightly smaller than the product 7.

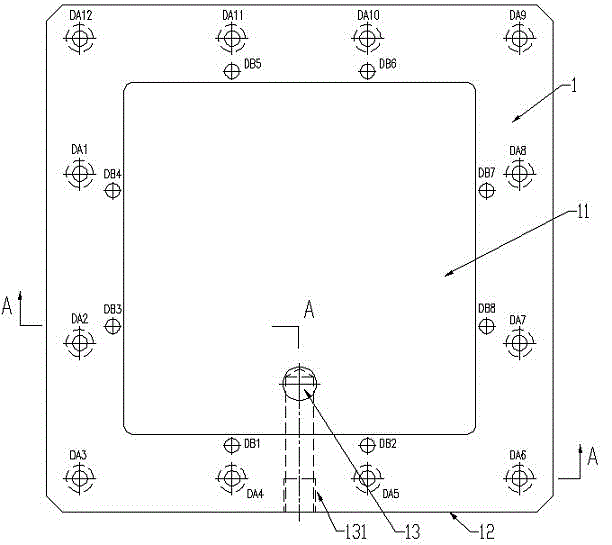

[0024] The structure of the lower mold 1 is as follows image 3 , Figure 4 As shown, the lower mold 1 is a square plate, and the upper surface 10 has a groove that is the same shape as the adhesive tape 8 but is smaller than the outer frame of the adhesive tape 8 by a circle. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com