High-efficiency multifunctional power tiller

A multi-functional micro-tiller technology, applied in the field of micro-tillers, can solve the problems of time-consuming and labor-intensive operation, poor effect, and easy rollover of micro-tillers, etc., and achieve the effect of saving time, effort and light operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

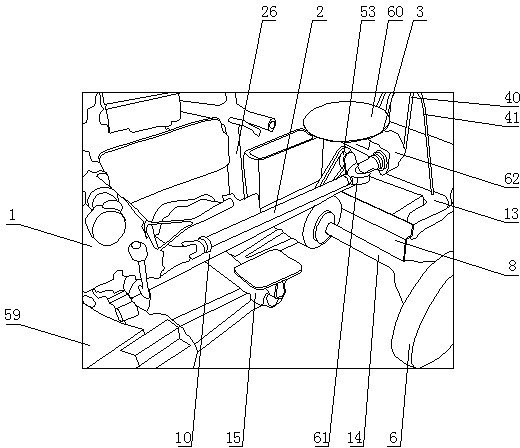

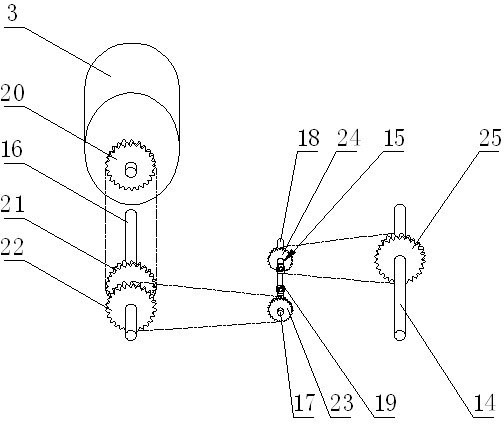

[0030] Such as Figure 1-7As shown, the high-efficiency multifunctional tiller includes engine 1 (gasoline engine is adopted in this embodiment), transmission shaft 2, speed reducer 3, front wheel 4, frame, rotary tiller shaft 5, steering mechanism, rear wheel 6 , wheel driving mechanism, rotary tiller group lifting mechanism, lifting locking mechanism and a vibration-proof mechanism that prevents rotary tiller shaft 5 from vibrating up and down during travel. The engine 1 drives the transmission shaft 2, and the transmission shaft 2 is connected with the worm 63 of the worm gear 62 through the steering universal joint 61, and the worm gear 64 of the worm gear 62 drives the power input shaft 65 of the speed reducer 3. The transmission shaft 2 drives the rotary tiller shaft 5 to rotate through the rotary tiller transmission part. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com