Insulated Composite Fabric

A composite fabric and fabric technology, applied in fabric surface trimming, textile and paper making, transportation and packaging, etc., can solve the problems of loss of heat insulation performance, poor air permeability, low air permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

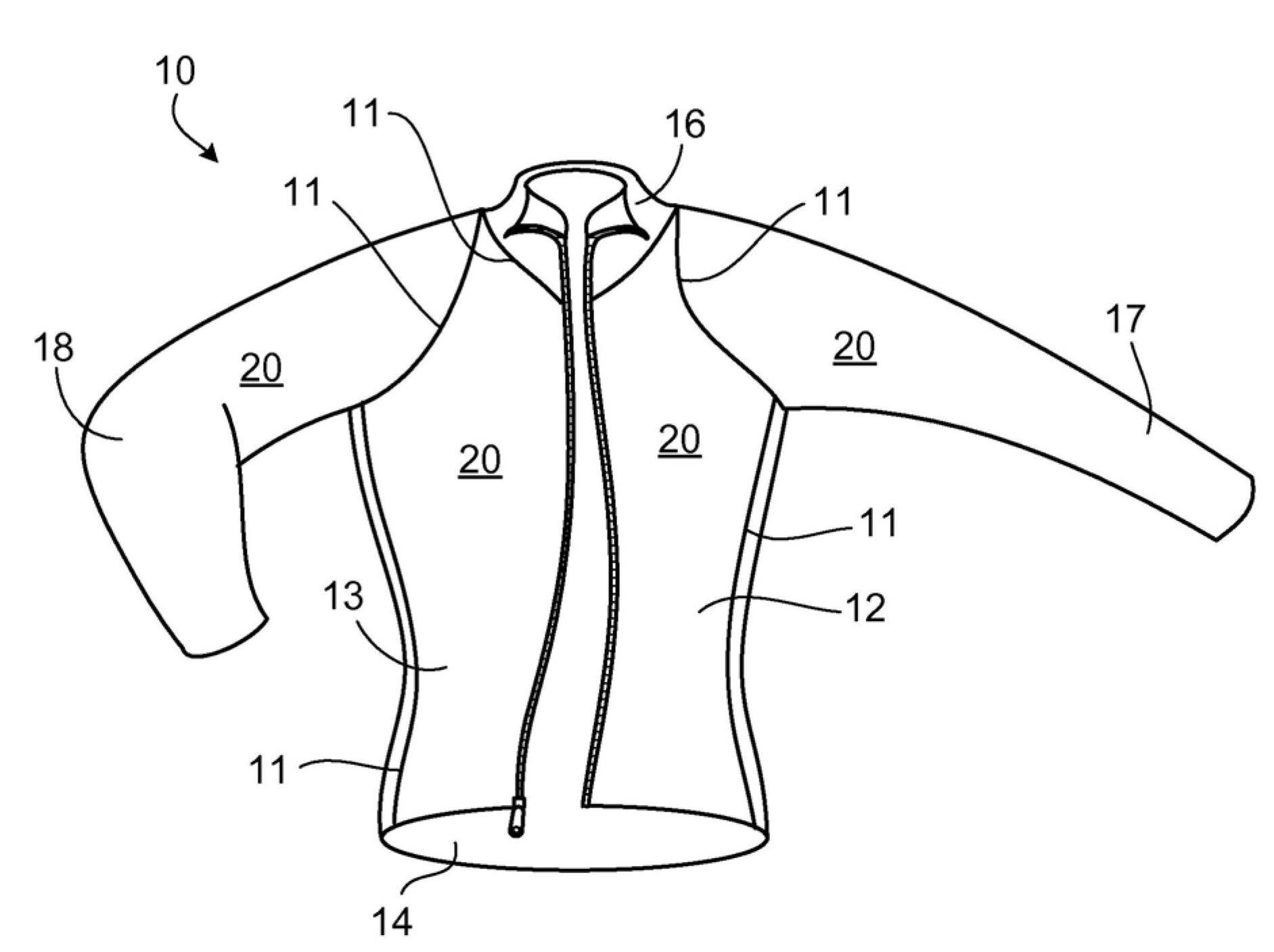

[0059] Figure 6An example of an insulating composite fabric 20' having a lightweight construction is shown. The fabric comprises an inner fabric layer 21', an outer fabric layer 22', and an insulating filler fabric layer 23' enclosed therebetween. Both the inner fabric layer 21' and the outer fabric layer 22' are composed of a knitted fabric having a mesh structure. The mesh structure of the inner and outer fabric layers 21', 22' has a plurality of openings 25. The heat-insulating filler fabric layer 23' is made of double-sided knitted fabric (such as double-sided warp knitted fabric, double-sided knitted fabric with pile loop sinker arc structure, or double-sided back pile knitted fabric), and its weight From about 1 ounce per square yard to about 4 ounces per square yard, with a bulk (thickness) of about 0.1 inch to about 0.2 inch. The insulating-fill fabric layer 23' is sewn (e.g. quilted) to one or both of the inner and outer fabric layers 21', 22'. The ligh...

example 2

[0061] Figure 7 The figure shows a heat-insulating composite fabric 20" of a medium structure. The heat-insulating composite fabric 20" of the medium structure includes an inner fabric layer 21" made of a knitted fabric with a mesh structure, and an outer fabric layer 21" made of a woven fabric. layer 22", and an insulating-filler fabric layer 23" enclosed therebetween. The insulating-filler fabric layer 23" is made of a double-knitted fabric (such as a double-sided warp-knitted fabric with pile loop settlement Double-knit fabric of raised sinker terry loop construction, or double-sided back pile knitted fabric (sliver knit)), having a weight of about 3 ounces per square yard to about 8 ounces per square yard, and a bulk density ( thickness) from about 0.15 inches to about 0.4 inches. The insulating filler fabric layer 23" is sewn (e.g., quilted) to one or both of the inner and outer fabric layers 21", 22". The insulating properties provided by the intermediate insulating co...

example 3

[0063] Figure 8 The figure shows a heavy-duty construction insulated composite fabric 20"'. The heavy-duty construction insulated composite fabric 20"' includes an inner fabric layer 21"', an outer fabric layer 22"', and Insulating filler fabric layer 23"'. In this heavy-duty construction, both the inner fabric layer 21"' and the outer fabric layer 22"' are constructed of woven fabric. The insulating filler fabric layer 23" 'Consisting of double-knit fabrics (such as double-knit warp knit, double-knit with pile loop sinker arc construction, or double-back pile knit) weighing from about 4 ounces per square yard to about 12 Ounces per square yard, with a bulk (thickness) of about 0.2 inches to about 1.0 inches. The insulating-fill fabric layer 23"' is sewn (eg, quilted) to one or both of the inner and outer fabric layers 21"', 22"'. The heavy-duty insulating composite fabric 20"' provides The thermal insulation performance is about 1.0clo / oz 2 to about 3.0clo / oz 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com